Novel anti-yellowing agent and preparation method thereof

An anti-yellowing agent, adamantane carbohydrazide technology, applied in fiber types, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of high impurity content in by-products, affecting finished products, human injury, etc., and achieve anti-yellowing effect Good, effective, high purity, and the effect of eliminating by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A novel anti-yellowing agent, described anti-yellowing agent comprises by mass parts:

[0042] 20 parts of N-(chloroacetyl)-adamantane carbohydrazide, 8 parts of alcoholamine, 4 parts of benzotriazole, 6 parts of o-acetylsalicylic acid, 6 parts of lauryl polyoxyethylene ether, 30 parts of urea and 40 parts of distilled water.

[0043] The preparation method of above-mentioned novel anti-yellowing agent, comprises the following steps:

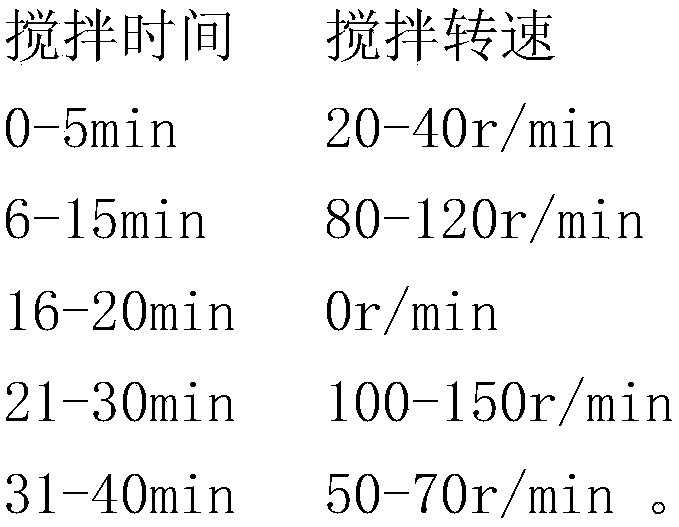

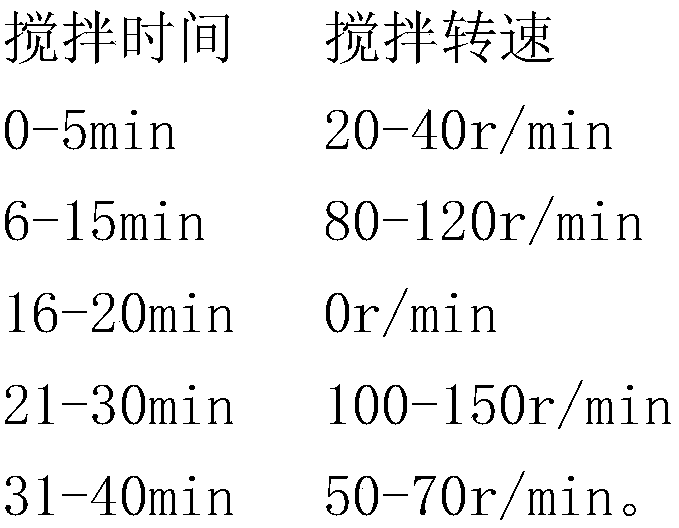

[0044] S1: Put N-(chloroacetyl)-adamantane carbohydrazide, alcohol amine, benzotriazole, and o-acetylsalicylic acid into a stainless steel emulsification stirring tank with a heating jacket, and use steam to heat and stir;

[0045] S2: Add urea and distilled water to continue stirring;

[0046] S3: Add lauryl polyoxyethylene ether, stir and homogenize;

[0047] S4: heat the solution obtained in S3 to reflux for 1.5-3h;

[0048] S5: Remove the solvent after the reaction, extract 2-5 times with absolute ethanol, collect the organic phas...

Embodiment 4

[0066] A novel anti-yellowing agent, described anti-yellowing agent comprises by mass parts:

[0067] 13 parts of N-(chloroacetyl)-adamantyl hydrazide, 3 parts of alcohol amine, 2 parts of benzotriazole, 3-15 parts of o-acetylsalicylic acid, 1 part of polyoxyethylene lauryl ether, 10 parts of urea and 30 parts of distilled water;

[0068] The preparation method is the same as in Example 1.

Embodiment 5

[0070] A novel anti-yellowing agent, described anti-yellowing agent comprises by mass parts:

[0071] 45 parts of N-(chloroacetyl)-adamantyl hydrazide, 12 parts of alcohol amine, 8 parts of benzotriazole, 15 parts of o-acetylsalicylic acid, 10 parts of lauryl polyoxyethylene ether, 40 parts of urea and 60 parts of distilled water;

[0072] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com