Preparation method and application of porous carbon material

A porous carbon material and reaction technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of secondary pollution, weak binding force, etc., and achieve enhanced adsorption capacity, optimized pore size and pore volume, Effects that enhance separation selectivity and binding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

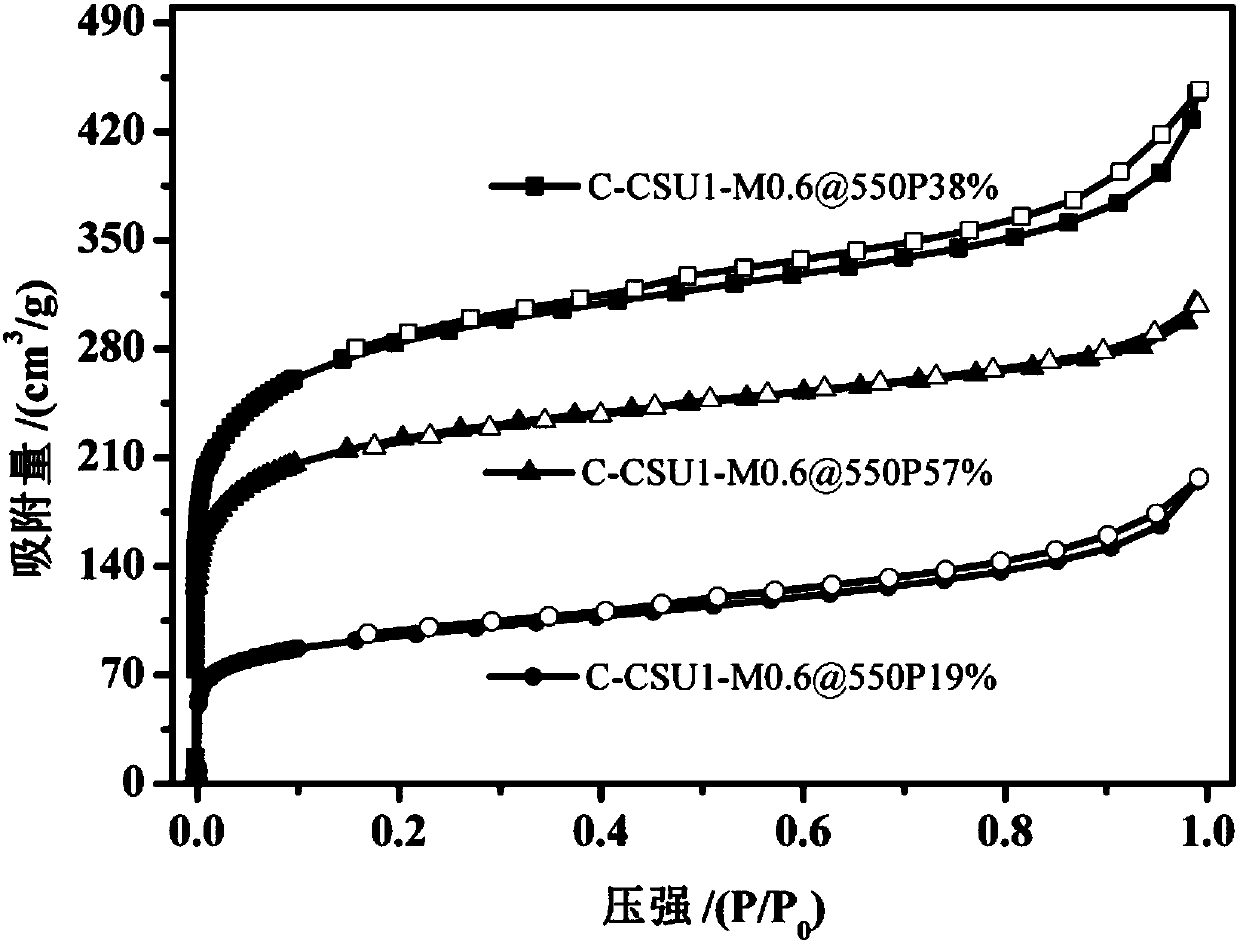

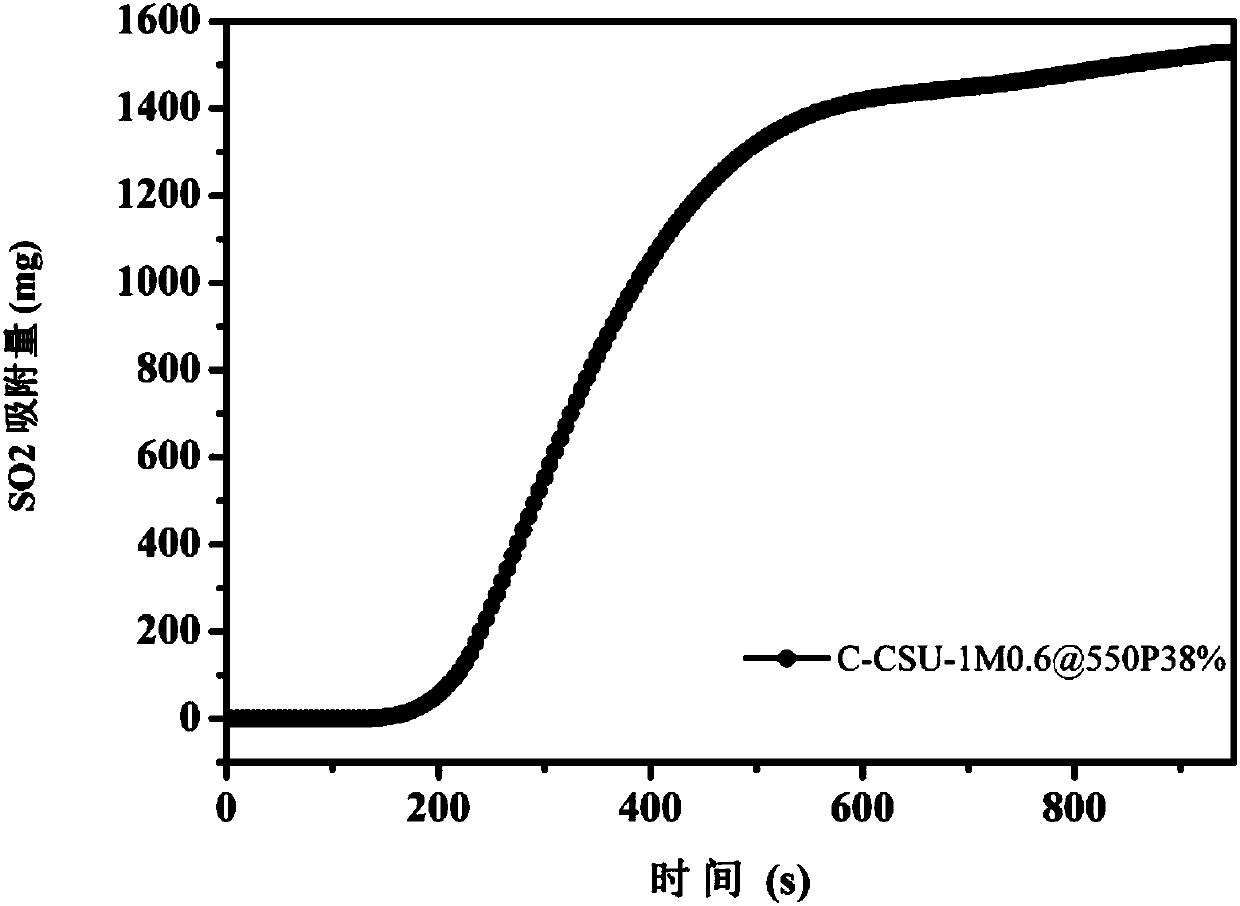

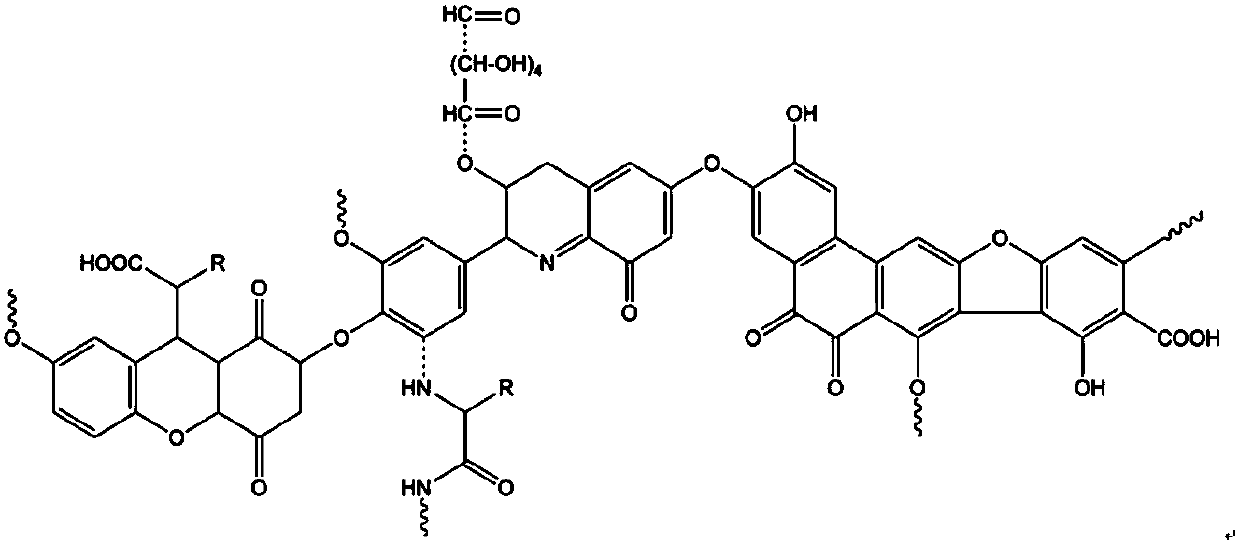

[0025] Get 15ml volume ratio and be the mixed solvent of ethanol / water of 2:1, add the humic acid 1.0g in lignite wherein, then add melamine 0.6g, after stirring and mixing, dropwise add PluronicP123 surfactant 0.5g wherein, The reaction was stirred for 0.5h to obtain a black mixture. The black mixture was dried in a vacuum oven at 80° C. for 12 hours. After the solvent was removed, a black solid was obtained.

[0026] 2.1 g of black solid was placed in 25 ml of KOH solution with a pH of 6M, and then the whole solution was placed in a vacuum oven and heated at 80° C. for 2 h to obtain a solid. Put the solid into a clean porcelain boat, in N 2 Under protection, activate at 200°C for 2 hours and at 550°C for 2 hours. After the activation is completed, add hydrochloric acid with a concentration of 3M to the solid until no gas is generated, then carry out vacuum filtration, and wash the filter residue with ion water for 3 times. And after drying, the nitrogen-doped porous carbon...

Embodiment 2

[0029] Get 15ml volume ratio and be the mixed solvent of ethanol / water of 2:1, add the humic acid 1.0g in lignite wherein, then add melamine 0.6g, after stirring and mixing, dropwise add PluronicP123 surfactant 1.0g wherein, The reaction was stirred for 0.5h to obtain a black mixture. The black mixture was dried in a vacuum oven at 80° C. for 12 hours. After the solvent was removed, a black solid was obtained.

[0030] 2.6 g of black solid was placed in 25 ml of pH 6M KOH solution, and then the whole solution was placed in a vacuum oven, and heated at 80° C. for 2 h to obtain a solid. Put the solid into a clean porcelain boat, in N 2 Under protection, activate at 200°C for 2 hours and at 550°C for 2 hours. After the activation is completed, add hydrochloric acid with a concentration of 3M to the solid until no gas is generated, then carry out vacuum filtration, and wash the filter residue with ion water for 3 times. And after drying, the nitrogen-doped porous carbon material...

Embodiment 3

[0033] Get 15ml volume ratio and be the mixed solvent of the ethanol / water of 2:1, add the humic acid 1.0g in lignite wherein, then add melamine 0.6g, after stirring and mixing, dropwise add PluronicP123 surfactant 1.5g wherein, The reaction was stirred for 0.5h to obtain a black mixture. The black mixture was dried in a vacuum oven at 80° C. for 12 hours. After the solvent was removed, a black solid was obtained.

[0034] 3.1 g of the black solid was placed in 25 ml of a pH 6M KOH solution, and then the whole solution was placed in a vacuum oven, and heated at 80° C. for 2 h to obtain a solid. Put the solid into a clean porcelain boat, in N 2 Under protection, activate at 200°C for 2 hours and at 550°C for 2 hours. After the activation is completed, add hydrochloric acid with a concentration of 3M to the solid until no gas is generated, then carry out vacuum filtration, and wash the filter residue with ion water for 3 times. And after drying, the nitrogen-doped porous carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com