Scheelite flotation collecting agent and preparation method thereof

A technology of scheelite and collector, which is applied in flotation, solid separation, etc., can solve the problems that collectors are easy to form micelles, high flotation temperature requirements, and poor indicators of concentrators, etc., and achieve good market promotion prospects , Improve mineral processing technical indicators, good effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

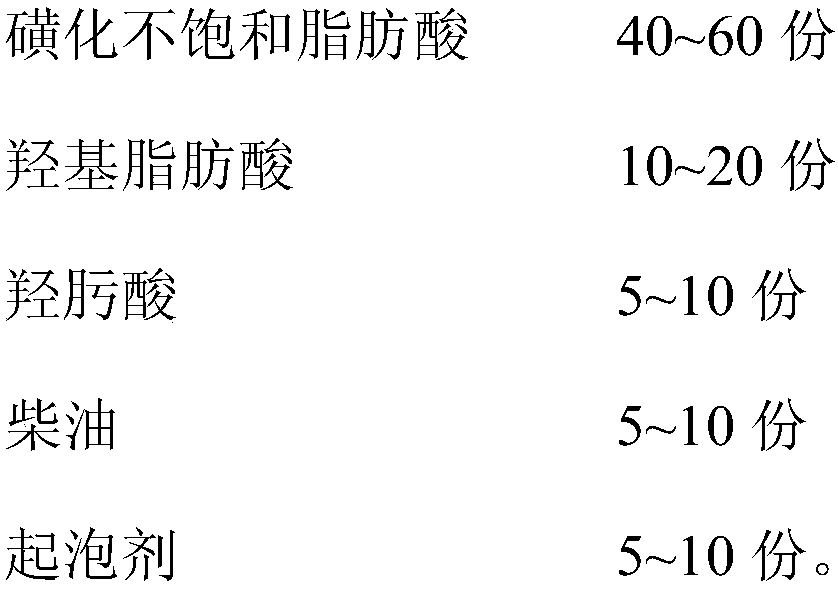

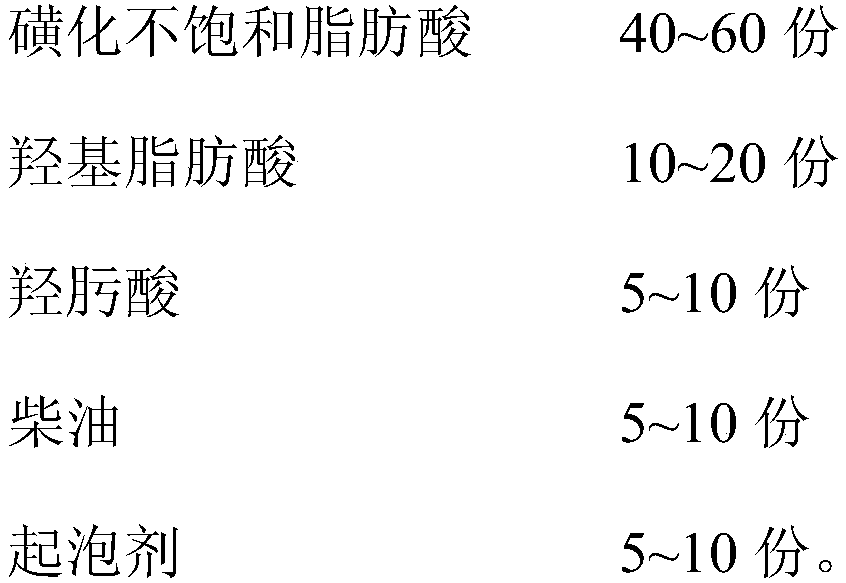

[0043] The preparation method of scheelite flotation collector of the present invention, described preparation method comprises the steps:

[0044] 1) In parts by weight, add 10 to 20 parts of hydroxy fatty acid, 5 to 10 parts of hydroxamic acid, 5 to 10 parts of diesel oil and 5 to 10 parts of Foaming agent, stir evenly to obtain compound mixture;

[0045] 2) Add lye to the compound mixture obtained in step 1), stir and undergo saponification reaction to obtain the scheelite flotation collector.

Embodiment 1

[0047] In parts by weight, weigh 45 parts of sulfonated oleic acid, 15 parts of hydroxy oleic acid, 5 parts of benzyl hydroxamic acid and 5 parts of -20# diesel oil, mix and stir at room temperature for 20 minutes, then add 7 parts of foaming agent pine Alcohol oil, after continuing to stir for 20 min, a homogeneous mixture was obtained. Dissolve 15 parts of sodium hydroxide in 100 parts of water, then slowly add it to the above mixture, stir evenly at 30°C and react for 90 minutes to fully saponify it to obtain a scheelite flotation collector.

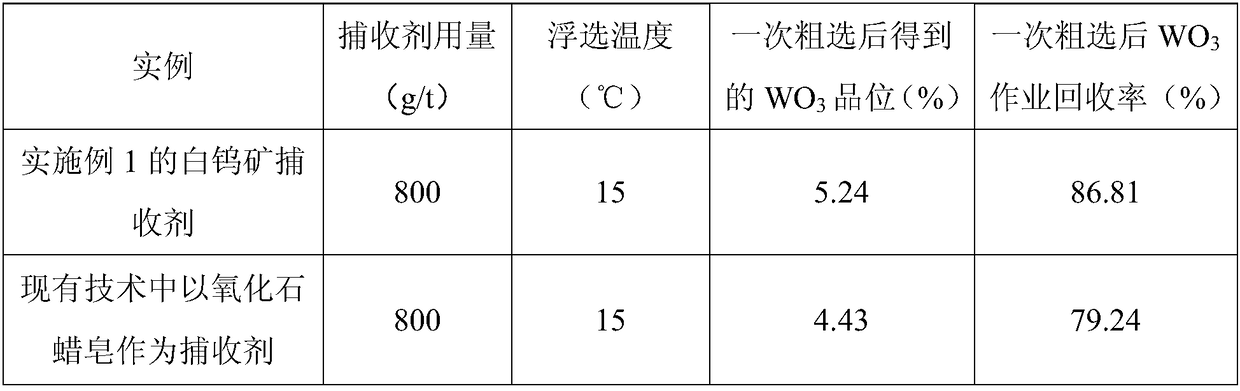

[0048] Using the scheelite flotation collector provided in Example 1 of the present invention and the technical scheme of using oxidized paraffin wax soap as the collector in the prior art to carry out comparative tests: the ore sample WO 3 The grade is 0.39%, and sodium carbonate is used to adjust the pH of the pulp to 9.5-10.0, and then 3000 g / t of water glass is added to suppress the gangue. The performance and effect comparison be...

Embodiment 2

[0054] In parts by weight, weigh 50 parts of sulfonated oleic acid, 10 parts of hydroxystearic acid, 10 parts of naphthalene hydroxamic acid and 10 parts of -10# diesel oil, mix and stir at room temperature for 20 minutes, and then add 10 parts of foaming agent MIBC , and continue to stir for 20 min to obtain a homogeneous mixture. Dissolve 17 parts of sodium hydroxide in 100 parts of water, then slowly add it to the above mixture, stir evenly at 32°C and react for 75 minutes to fully saponify it to obtain a scheelite flotation collector.

[0055] Using the scheelite flotation collector provided in Example 2 of the present invention and the technical scheme using oleic acid as the collector in the prior art to carry out a comparative test: the selected ore sample WO 3 The grade is 0.67%, and sodium carbonate is used to adjust the pH of the pulp to 9.5-10.0, and then 3000g / t of water glass is added to suppress the gangue. The performance and effect of the two are compared as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com