Partially hydrolyzed acrylamide polymer suitable for serving as supermolecule coating agent with high temperature resistance, water-based drilling fluid, and application of water-based drilling fluid

A technology for hydrolyzing acrylamide and water-based drilling fluid, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature resistance (not exceeding 150°C, narrow applicable surface, difficult to meet on-site construction, etc.) , to achieve the effect of excellent inhibition of drill cuttings dispersion, improvement of temperature resistance, and excellent high temperature resistance coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The second aspect of the present invention provides a method for preparing a partially hydrolyzed acrylamide polymer, the method comprising:

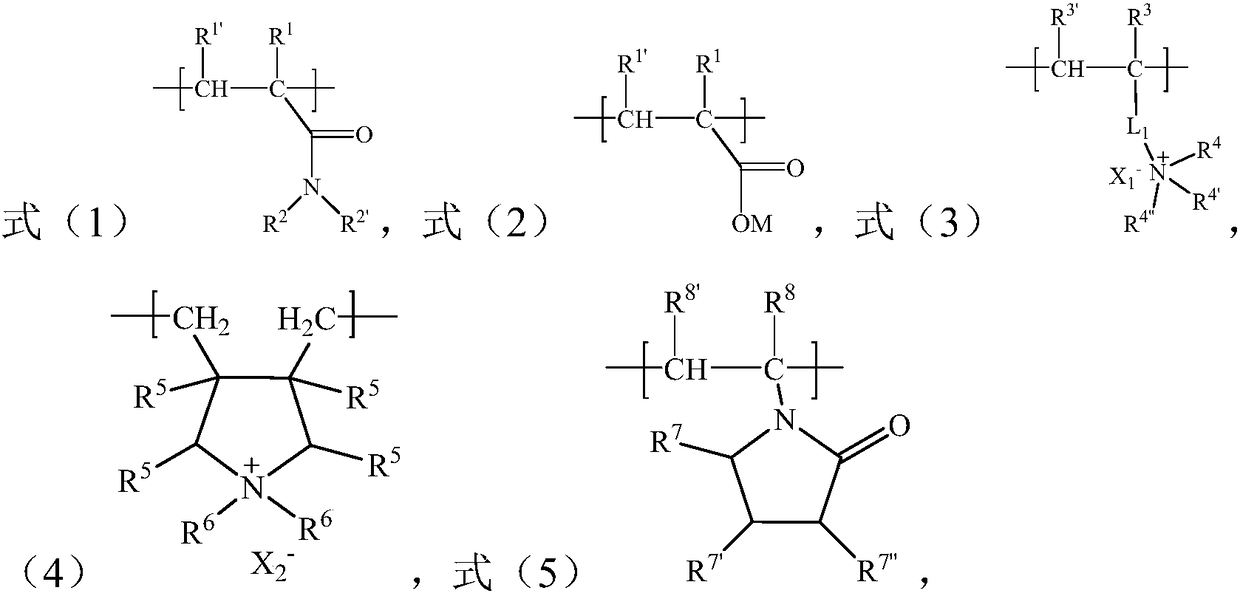

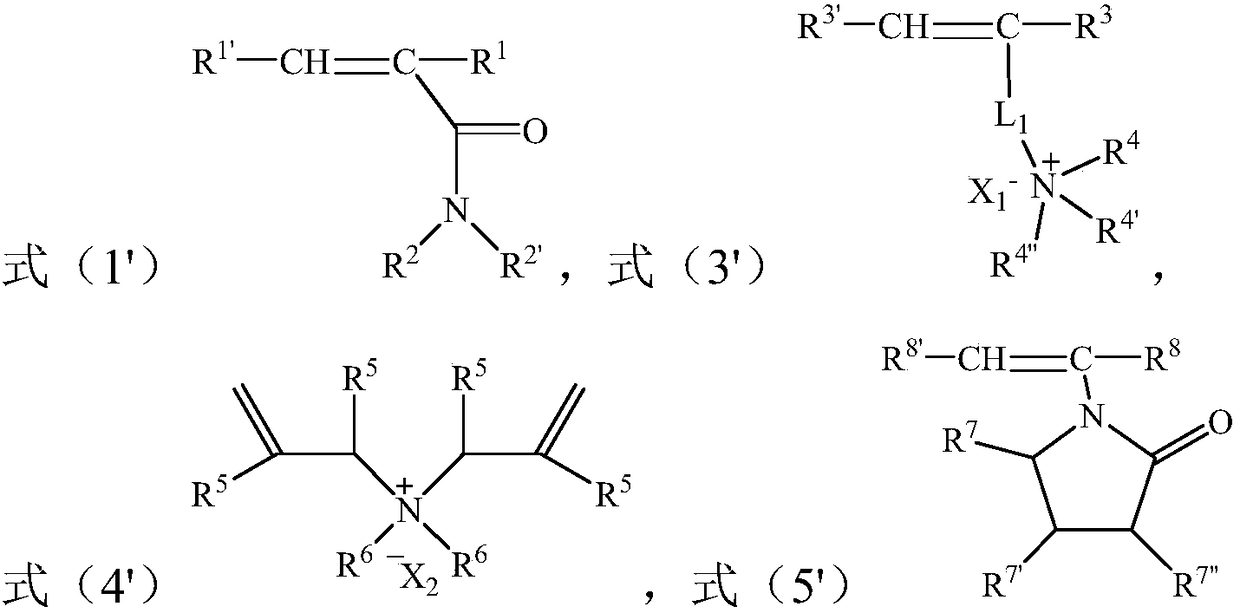

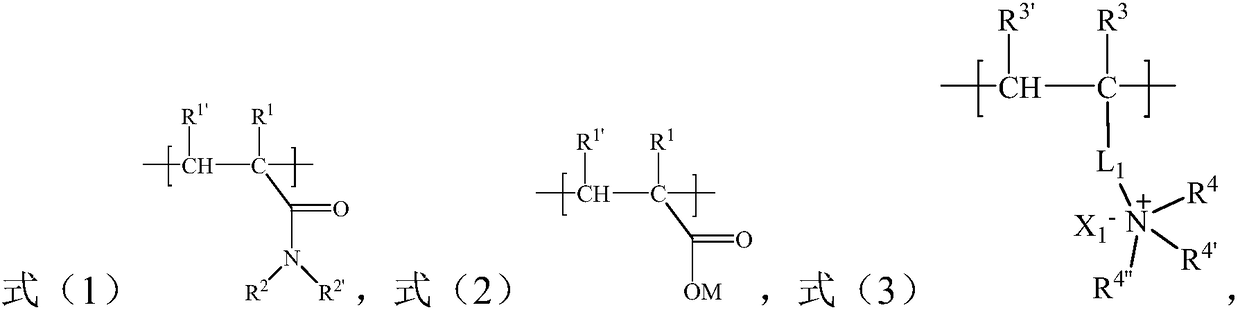

[0035] (1) In an aqueous solvent, in the presence of a free radical initiator, the compound shown in formula (1'), the cationic monomer and the compound shown in formula (5') are subjected to free radical polymerization; The cation-containing monomer is a compound represented by formula (3') and / or a compound represented by formula (4');

[0036] (2) In an aqueous solution of alkali metal hydroxide, the product of the radical polymerization reaction is hydrolyzed to obtain a partially hydrolyzed acrylamide polymer;

[0037] Wherein, the method makes the obtained partially hydrolyzed acrylamide polymer have a number average molecular weight of 5 million to 10 million;

[0038]

[0039] Among them, R 1 , R 1 ', R 2 , R 2 ', R 3 , R 3 ', R 5 , R 8 and R 8 ' each independently selected from H and C1-C6 alkyl; R 4 , R 4...

Embodiment 1

[0126] This example is used to illustrate the partially hydrolyzed acrylamide polymer of the present invention and its preparation method.

[0127] (1) Dissolve 222mmol of acrylamide, 56mmol of allyltrimethylammonium chloride and 22mmol of a compound represented by formula (5'-1) (purchased from Mobe Chemical, the same below) in 200mL of deionized water, Stirring at 300r / min, blow nitrogen for 30min to remove oxygen, add 0.36mmol ammonium persulfate, continue nitrogen blowing for 10min, then add 0.24mmol sodium bisulfite, polymerize at 30°C for 7h;

[0128] (2) Add 2 mol / L sodium hydroxide aqueous solution (the amount of sodium hydroxide is 89mmol) to the polymerization reaction system, stir evenly, then raise the temperature to 80°C and stir and react at 300r / min for 8h until no gas is released in the system, stop the reaction , cooled to room temperature, dried and crushed to obtain partially hydrolyzed acrylamide polymer P1.

Embodiment 2

[0131] This example is used to illustrate the partially hydrolyzed acrylamide polymer of the present invention and its preparation method.

[0132] (1) Dissolve 387mmol of N,N-dimethylacrylamide, 135mmol of allyltrimethylammonium chloride and 78mmol of the compound shown in formula (5'-1) in 200mL of deionized water, at 300r / Under stirring for 1 min, blow nitrogen for 30 min to remove oxygen, add 0.9 mmol of azobisisobutylamidine dihydrochloride, and polymerize at 50°C for 6 h;

[0133] (2) Add 2 mol / L sodium hydroxide aqueous solution (the amount of sodium hydroxide is 194 mmol) to the polymerization reaction system, stir evenly, then raise the temperature to 70°C and stir and react at 300r / min for 9h until no gas is released in the system, stop the reaction , cooled to room temperature, dried and pulverized to obtain partially hydrolyzed acrylamide polymer P2.

[0134] Through infrared, hydrogen nuclear magnetic resonance spectrum and carbon spectrum analysis detection, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com