Ester-ether mixed structure mud-resistant polycarboxylate superplasticizer and preparation method thereof

A mixed structure, mud-resistant technology, applied in the field of concrete admixtures, can solve the problems of single molecular structure, long synthesis time, poor mud resistance, etc., and achieve the effect of simple process, easy control of reaction conditions, and good slump performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

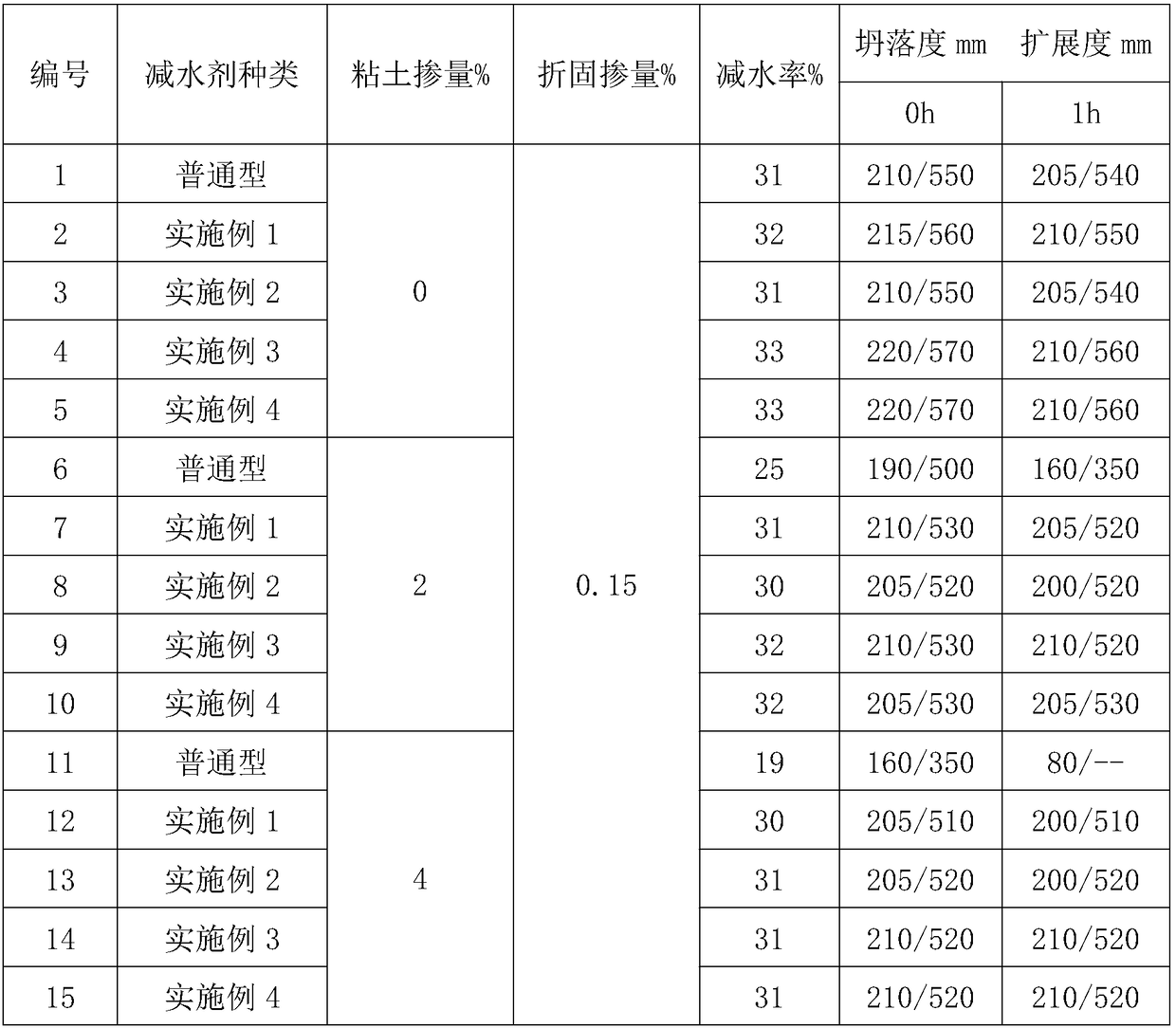

Examples

Embodiment 1

[0027] Example 1: Preparation of mud-resistant polycarboxylate superplasticizer with ester-ether mixed structure

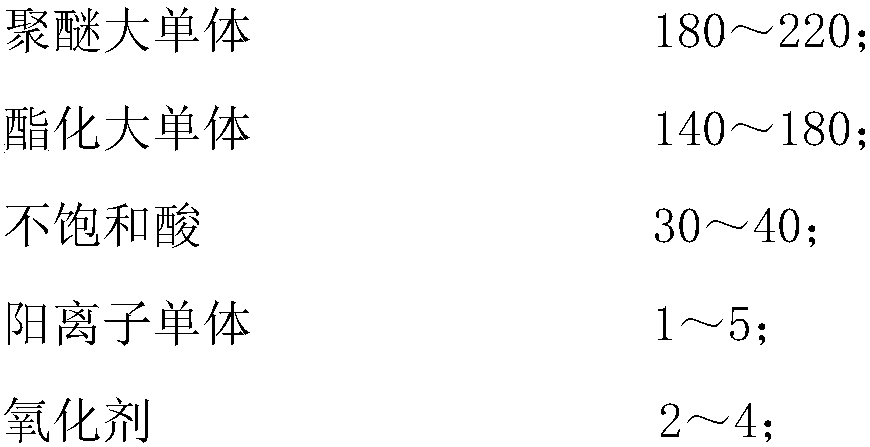

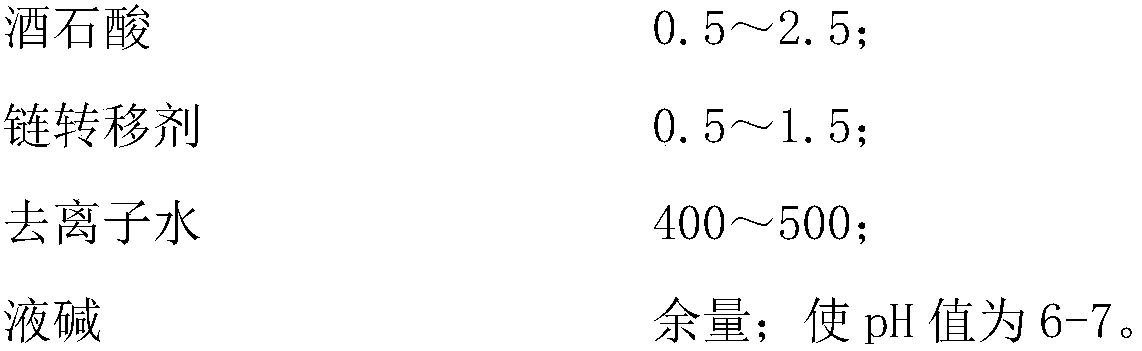

[0028] Raw materials: see Table 1. Among them, the polyether macromonomer is isobutenyl alcohol polyoxyethylene ether (molecular weight 2400); the esterification macromonomer is methoxy polyethylene glycol methyl methacrylate (molecular weight 1200); the unsaturated acid is acrylic acid; the cationic monomer It is methacryloyloxyethyltrimethylammonium chloride; the oxidizing agent is hydrogen peroxide; the chain transfer agent is mercaptoethanol.

[0029] The consumption table (parts by weight) of each composition of table 1 embodiment 1-5

[0030]

Example 1

Example 2

Example 3

Example 4

polyether macromonomer

210

200

180

220

Esterified macromonomer

150

160

180

140

unsaturated acid

33

35

30

40

cationic monomer

2

1

5

1

3

4

2

2

...

Embodiment 2

[0037] Example 2: Preparation of mud-resistant polycarboxylate superplasticizer with ester-ether mixed structure

[0038] Raw materials: see Table 1. Among them, the polyether macromonomer is isopentenol polyoxyethylene ether (molecular weight 2400); the esterification macromonomer is methoxy polyethylene glycol methyl acrylate (molecular weight 1200); the unsaturated acid is methacrylic acid; The monomer is acryloyloxyethyltrimethylammonium chloride; the oxidizing agent is ammonium persulfate; the chain transfer agent is thioglycolic acid.

[0039] Preparation method: The dropping time is 3 hours, and the temperature is maintained for 1 hour after the dropping. Other steps are all the same as in Example 1.

Embodiment 3

[0040] Example 3: Preparation of mud-resistant polycarboxylate superplasticizer with ester-ether mixed structure

[0041] Raw materials: see Table 1. The polyether macromonomer is 4-hydroxybutyl vinyl ether (molecular weight 2400); the esterification macromonomer is methoxy polyethylene glycol methyl methacrylate (molecular weight 1200); the unsaturated acid is methacrylic acid ; The cationic monomer is acryloyloxyethyltrimethylammonium chloride; the oxidizing agent is sodium persulfate; the chain transfer agent is 3-mercaptopropionic acid.

[0042] Preparation method: The dropping time is 2.5 hours, and the temperature is maintained for 1 hour after the dropping. Other steps are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com