Preparation method for manganous silicate/carbon water system button-type supercapacitor

A supercapacitor, manganese silicate technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc. performance and other issues, to achieve the effect of simple structure, increased cycle life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

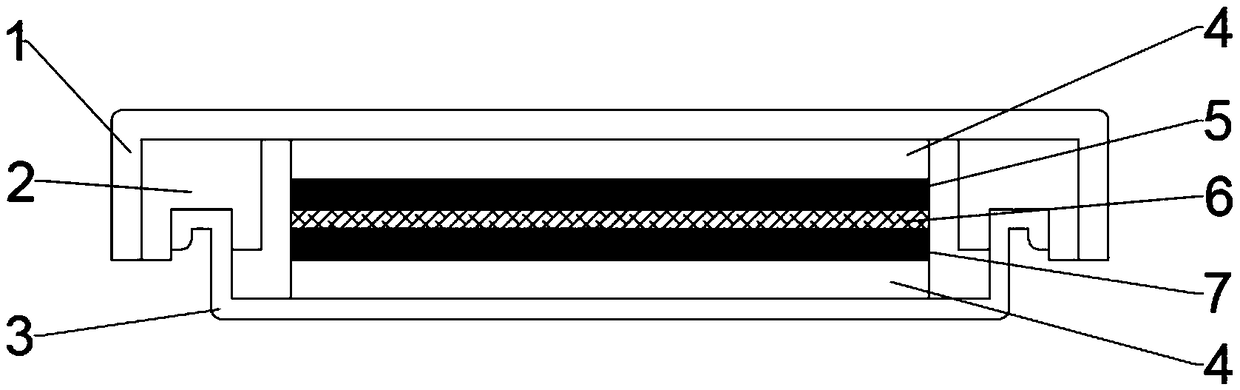

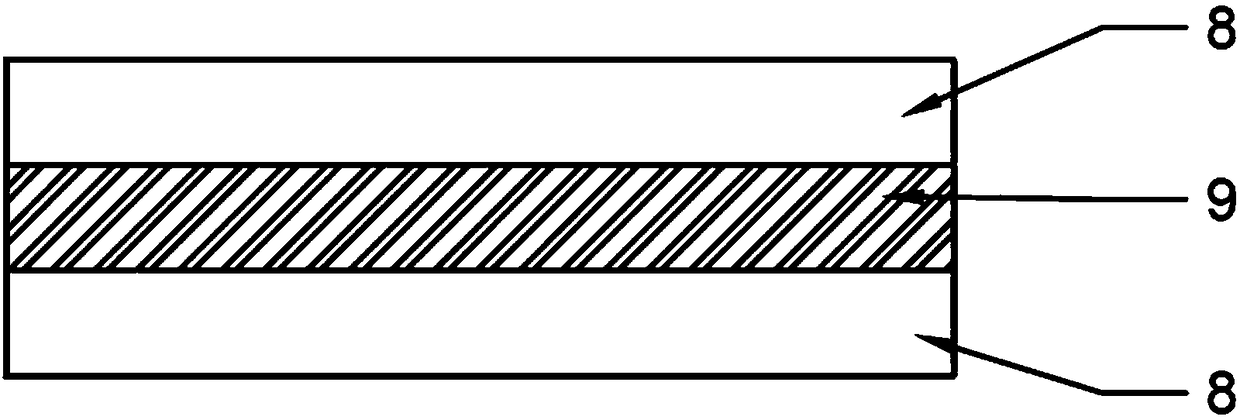

[0020] 1. After dispersing the manganese silicate / carbon (10% carbon mass percentage) material with a mass ratio of 8.5:1:0.5, acetylene black and PTFE, adding a dispersant absolute ethanol, stirring for 30 minutes, ultrasonication for 10 minutes, Grind for 10 minutes and mix evenly to form a black positive electrode slurry; put the positive electrode slurry in a blast oven at 105°C and completely dry (drying time is determined according to the actual weight of the mixture) to obtain a black powder positive electrode material mixture ;

[0021] 2. After dispersing the activated carbon material, acetylene black and PTFE with a mass ratio of 8.5:1:0.5, add dispersant absolute ethanol, stir for 30 minutes, ultrasonic for 10 minutes, grind for 10 minutes, and mix evenly to form a black negative electrode slurry Put the negative electrode slurry into a blast oven at 105°C and completely dry (drying time is determined according to the actual weight of the mixture) to obtain a black ...

Embodiment 2

[0026] The negative electrode material loading in step 3 is about 8 mg cm -2 ; In step 4, pre-soak the positive electrode sheet (5) and the negative electrode sheet (7) with 1M potassium hydroxide electrolyte for 20 minutes, and pre-soak the cellulose diaphragm (6) with potassium hydroxide electrolyte for 1 minute to make them fully wet; All the other are with embodiment 1.

[0027] The supercapacitor device assembled by this method has a rated voltage of 1.4V and a maximum capacitance of 0.6F; based on the mass of the electrode material, the maximum energy density reaches 4Wh kg-1 , the maximum power density reaches 1000W kg -1 ; 1000 laps capacitor retention rate is 60%.

Embodiment 3

[0029] In step 1, the mass proportion of manganese silicate / carbon material (carbon mass percent is 10%), acetylene black and PTFE is 8:1:1; In step 2, the mass proportion of activated carbon material, acetylene black and PTFE is 8: 1:1; All the other are with embodiment 1.

[0030] The supercapacitor device assembled by this method has a rated voltage of 2.0V and a maximum capacitance of 1.3F; based on the mass of the electrode material, the maximum energy density reaches 16Wh kg -1 , the maximum power density reaches 6000W kg -1 ; 1000 laps capacitor retention rate is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com