A method to realize enhanced III-V HEMT devices using all-solid-state batteries

A III-VHEMT, all-solid-state battery technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as depletion, difficulty in precise control, and reliability, and achieve high Performance, Effect of High Electron Mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

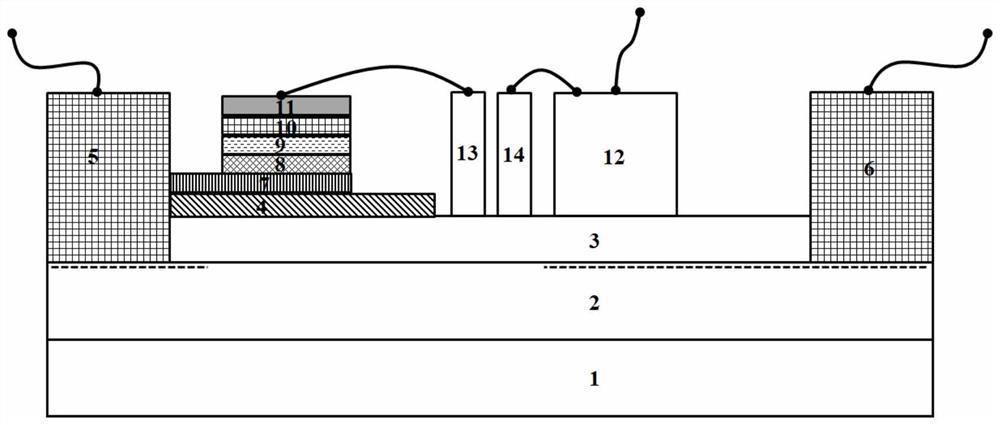

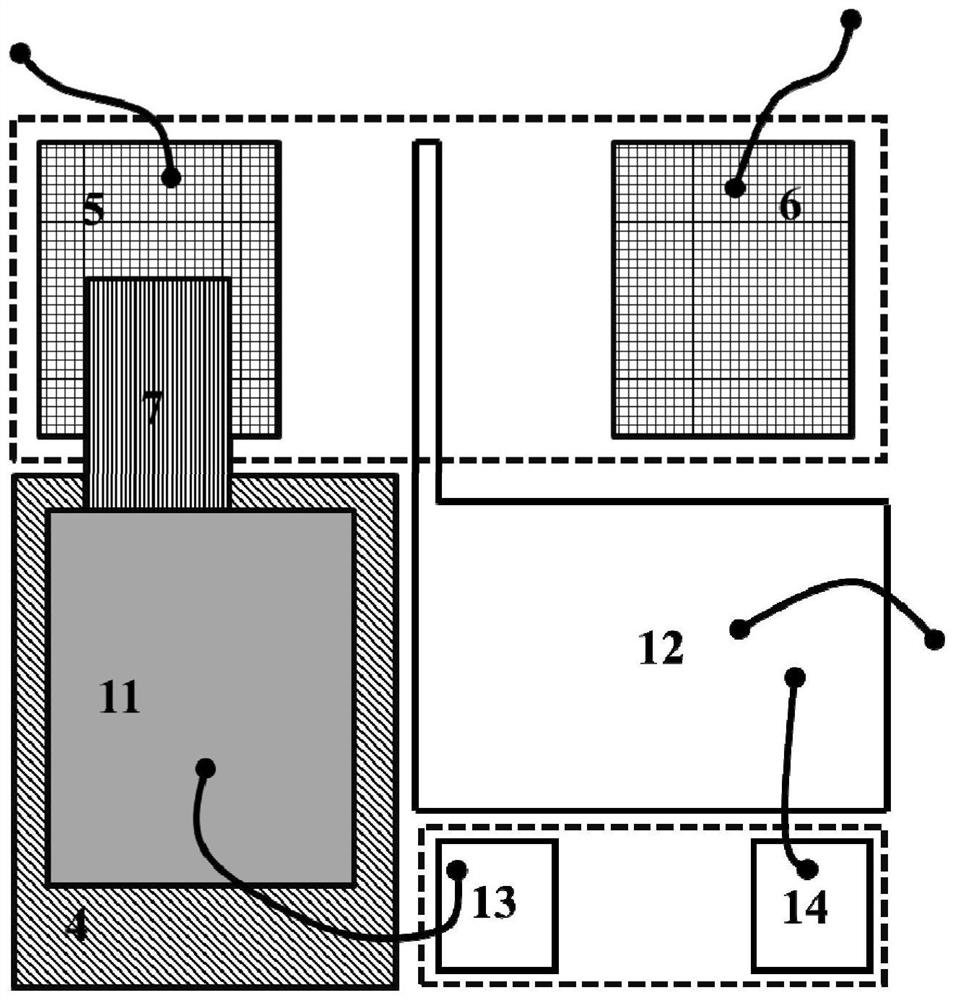

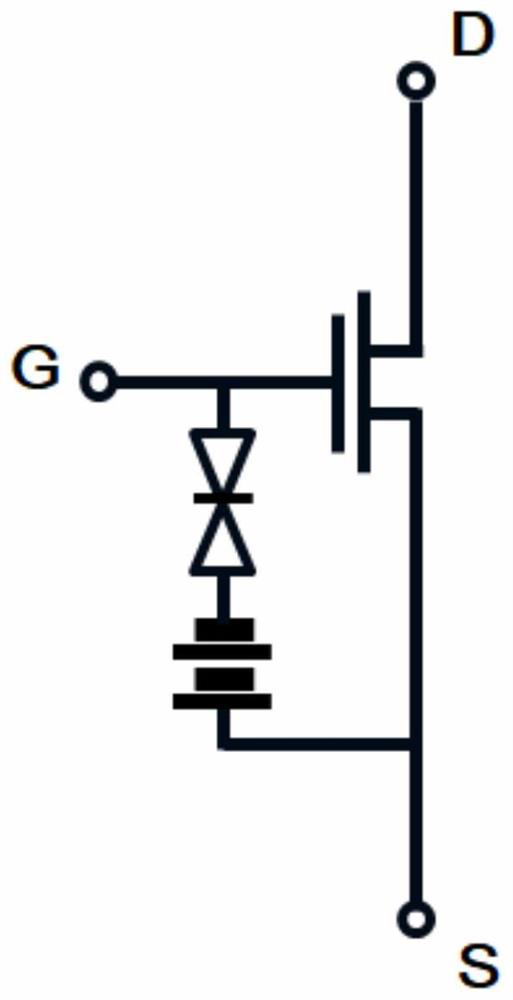

[0059] refer to figure 1 , the basic HEMT of the device is AlGaN / GaN HEMT. Its isolation insulating layer is Si 3 N 4 , with a thickness of 100-200nm, prepared by LPCVD process.

[0060] Si by electron beam evaporation 3 N 4 A 150nm Ni metal layer is sputtered on the top, and then a lithium phosphate ceramic target is used as a sputtering source, and a 500-2000nm LiPON thin film is prepared on the Ni metal by radio frequency magnetron sputtering. Second, 250nm LiCoO was sputtered on the LiPON film 2 film. After that in LiCoO 2 Evaporate Ti / platinum Pt metal with a thickness of 10 / 200nm on the film, and finally make a gate electrode and a diode pair on the surface of AlGaN. The anode metal of the diode is Ni / Au (50 / 200nm), and the turn-on voltage of the single-stage diode is about 1~ 1.5V, and finally the basic HEMT device is electrically connected to the all-solid-state battery and the diode pair through wire bonding technology.

[0061] Further, the area occupied by ...

Embodiment 2

[0063] The base HEMT for this device is an AlN / GaN HEMT. Its isolation insulating layer is Si 3 N 4 , with a thickness of 300nm, prepared by LPCVD process.

[0064] Using radio frequency magnetron sputtering method on 300nm thick Si 3 N 4 250nm Ti metal was deposited on it, followed by LiMn 2 o 4 The target is a sputtering source, and 800nm LiMn is prepared on Ti metal by radio frequency magnetron sputtering. 2 o 4 film, then with Li 3 PO 4 As the sputtering source, in LiMn 2 o 4 A 500nm LiPON film is prepared on the film as an all-solid electrolyte, followed by a 450nm ZnO film on the LiPON film, then a 250nm Ti metal on the ZnO film layer, and finally a gate electrode and a diode pair on the AlN surface, the anode metal of the diode Using Ni / Au (50 / 200nm), the turn-on voltage of the single-stage diode is about 1-1.5V. Finally, the basic HEMT device, the all-solid-state battery and the diode pair are electrically connected by wire bonding technology.

[0065] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com