Straw bioreactor as well as preparation method thereof and greenhouse vegetable cultivation method

A straw biology and cultivation method technology, applied in the field of bioreactors, can solve the problems of less obvious reactor effects, easy to produce fruits and vegetables, and poor effects, and achieve the effects of improving disease resistance, promoting transformation, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

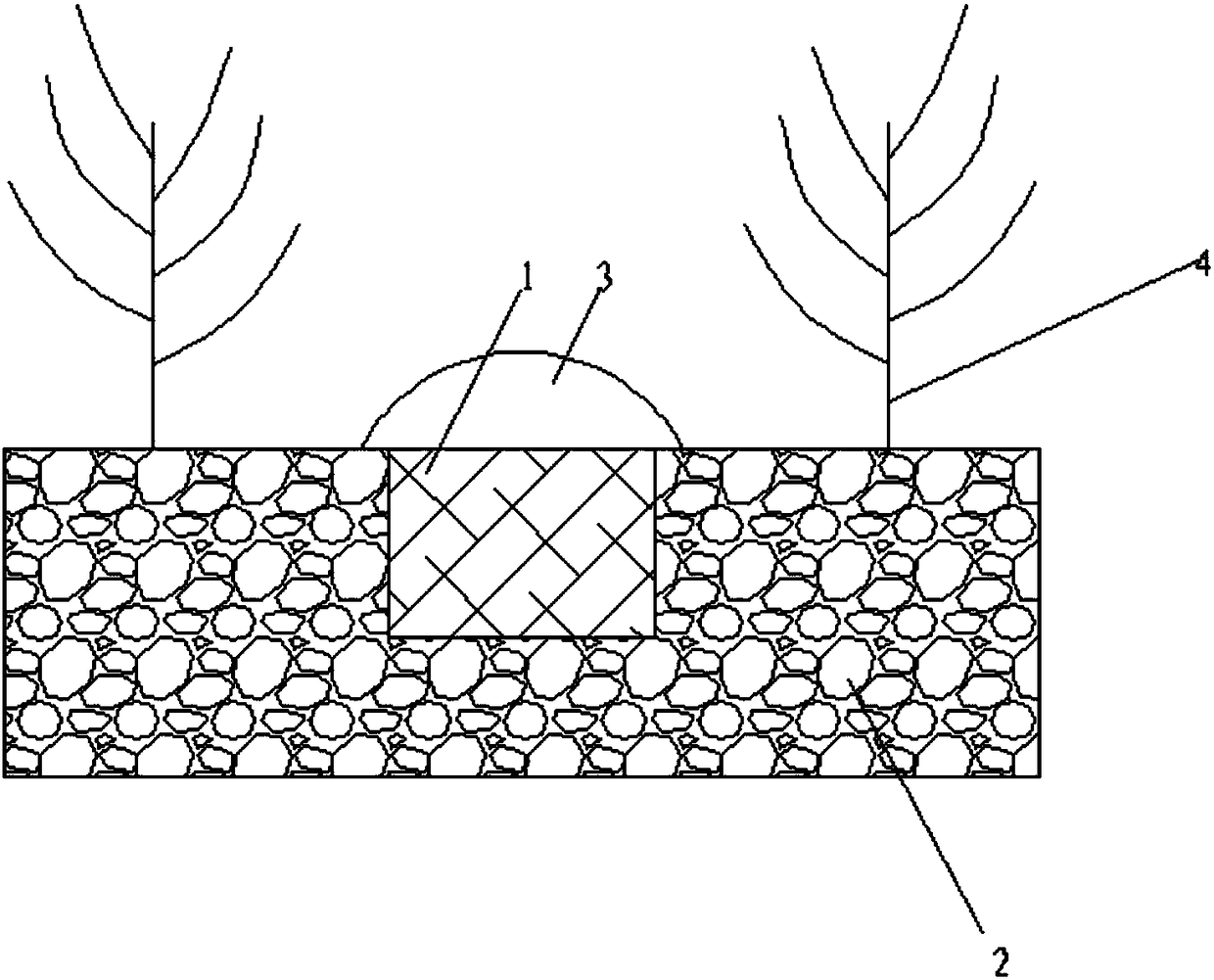

[0036] Such as Figure 1 to Figure 2 As shown, a straw bioreactor, the straw bioreactor 1 is arranged in the groove of the greenhouse soil 2 in a strip shape, including straw, organic materials, fermentation bacteria agents, and amino acid additives; including 100 parts by weight of straw, organic 10-30 parts of materials, 0.1-0.3 parts of fermentation bacteria agent, 0.2-0.5 parts of amino acid-containing additive; the amino acid-containing additive contains seaweed polysaccharide and chitosan extracted from marine organisms.

[0037] As preferably, in the present embodiment: fermenting agent is aerobic fermenting agent, and it comprises cellulomonas, Pseudomonas, Aspergillus niger, Trichoderma viride, Trichoderma aculeatus, Phanerochaete chrysosporium, Mycelium fermentum, Bacillus, Thermomonospora, Streptomyces, Clostridium thermocellum, Lactic acid bacteria.

[0038] As a preference, in this embodiment: the amino acid-containing additive is made of deep-sea fish and shrimp...

Embodiment 2

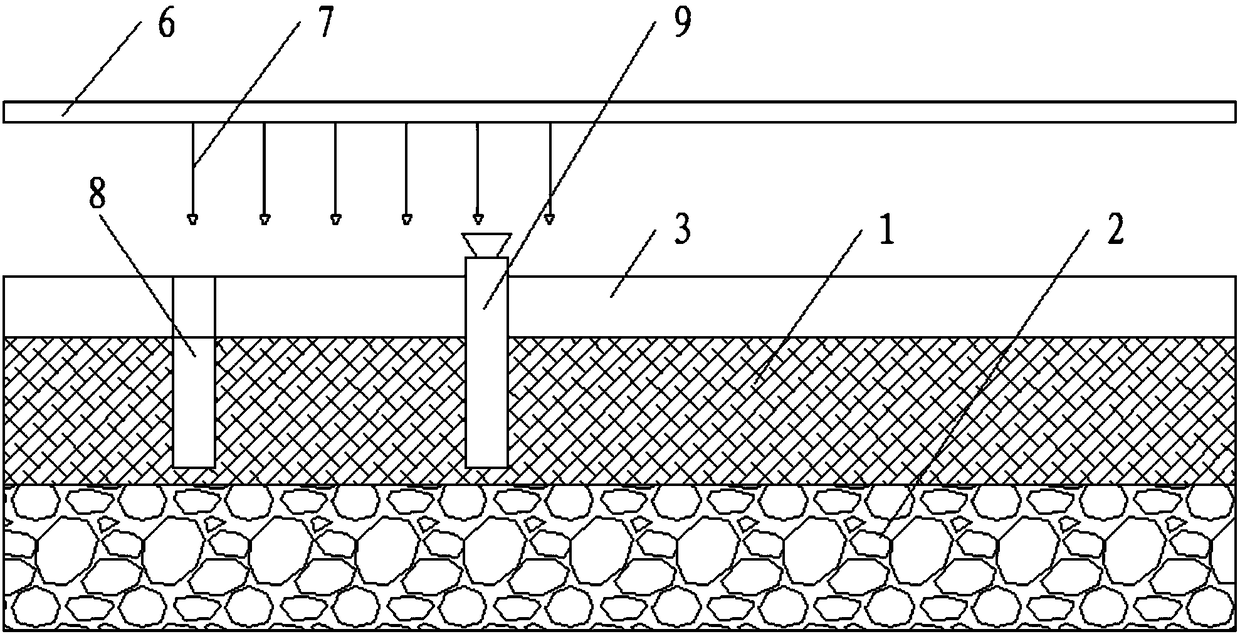

[0053] In combination with Example 1 and Figure 1 to Figure 2 , a straw bioreactor greenhouse vegetable cultivation method, when greenhouse vegetables are cultivated, at least one straw bioreactor and reaction auxiliary equipment are vertically arranged in the greenhouse soil, greenhouse vegetables or melons and fruits are planted on both sides of the straw bioreactor 4, and the reaction auxiliary equipment is used To water or add liquid fertilizer to the biological reactor, the reaction auxiliary equipment includes a drip irrigation pipe 6 and a drip irrigation head 7 .

[0054] Preferably, in this embodiment: greenhouse vegetables are planted about 7-10 days after the completion of the straw bioreactor, and the planted vegetables are raised in nutrient pots and transplanted with soil. When transplanting, the roots of the seedlings should be greater than or equal to 5cm away from the straw reactor.

[0055] Preferably, in this embodiment: vegetables are mainly solanaceous cr...

Embodiment 3

[0058] In combination with Example 2 and image 3 , In this embodiment, the lamp tube in the reaction auxiliary equipment is also used to promote the reaction of photosynthetic bacteria and add photosynthetic bacteria. This embodiment is mainly applied to greenhouse planting bases with relatively high technical level and scale. Combined with the equipment of this embodiment, higher yields can be obtained.

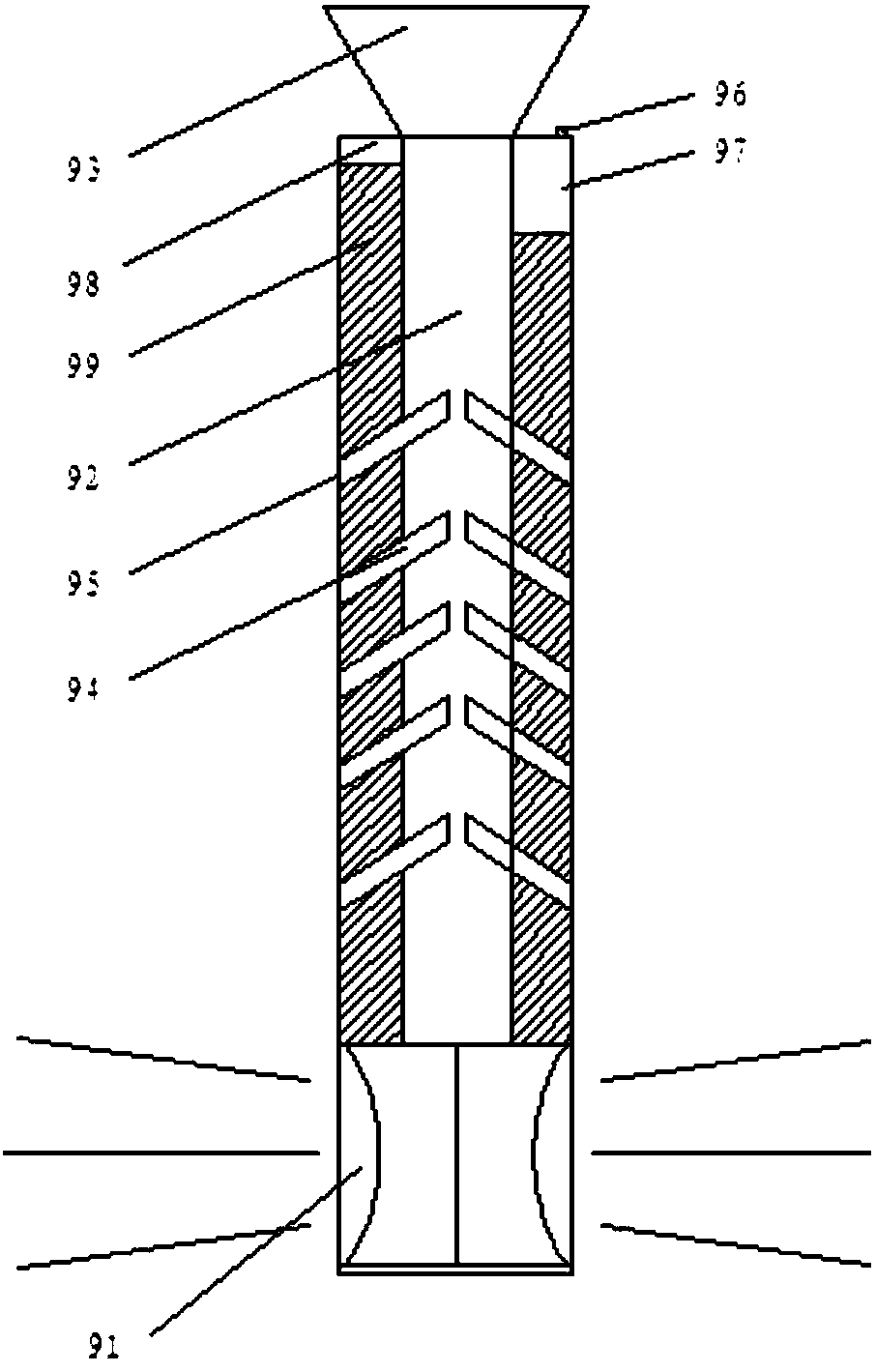

[0059] As a preference, in this embodiment: the reaction auxiliary equipment also includes an annular lamp tube 9 that can be inserted into the vent hole 8, and the two ends of the bottom of the lamp tube 9 are respectively provided with an LED direct light 91, and the lamp tube 9 is provided with a photosynthetic bacteria addition bin 92 and a funnel 93 with a switch in the center, the addition bin is connected to the bacteria release hole 95 on the outer wall of the lamp tube through a plurality of inclined tubes 94, and the top of the lamp tube 1 is provided with a swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com