Functional ginger juice and black bean yoghourt good in flavor and production method of functional ginger juice and black bean yoghourt good in flavor

A production method and functional technology, applied in the field of production technology of soybean yogurt, can solve the problems of insignificant function, poor flavor, affecting product application value and health care efficacy, etc., achieve strong antioxidant activity, and improve product texture. , enhance the effect of antioxidant function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Screening, domestication, identification and sugar utilization test of bacterial strain ST3

[0052] (1) Inoculate XPL-1 (5 strains including Lactococcus lactis subsp.Cremoris, Lactococcus lactissubsp.Lactis, Leuconostoc mesenteorides subsp.cremoris, Lactococcus lactissubsp.lactis biovar diacetylactis, Streptococcus thermophilus) into soybean milk, activate at 42°C for 6h, and It is put into fresh sterilized soybean milk, fermented at 42°C for 12 hours, and repeated 3-4 times for domestication. Dilute the fermented soybean milk to 10 with sterile water -3 、10 -4 、10 -5 times, smeared on Elliker agar medium, cultured at 42°C for 48h, and picked a single colony. The purified strains were numbered, inoculated in soybean milk medium, cultured at 42°C for 12 hours, and the strains that curd quickly were selected. The domestication and screening steps were repeated, and finally a strain ST3 with strong milk-clotting ability in soybean milk was obtained.

[0053...

Embodiment 2

[0056] Example 2 Isolation and identification of bacterial strain L.casei No.1

[0057] (1) Lactobacillus casei No. 1 (Lactobacillus casei NO1) is isolated from Guangdong kimchi. The isolation and purification method is as follows: Take 1ml of kimchi supernatant, dilute and spread it on MRS agar medium, culture it upside down at 37°C overnight, pick Take a single colony on the plate to obtain strain No. 1.

[0058] (2) The 16s rDNA of NO1 was extracted with a DNA extraction kit and subjected to agarose gel electrophoresis, and then its 16S rDNA primers were designed for PCR amplification. The purified and recovered DNA fragments were sequenced, and the sequencing results are shown in the sequence table SEQ.ID.NO2. Then, the BLAST software was used to compare with the reported 16Sr DNA, and the comparison results showed that the similarity between the DNA sequence and Lactobacillus casei was close to 100%.

[0059] (3) The strain is preserved in the Guangdong Microbial Cultur...

Embodiment 3

[0060] Example 3 Streptococcus thermophilus ST3 combined with L.casei-01 fermented black soybean milk (comparative example)

[0061] (1) Take 100g of black beans that have been selected and removed, add 400mL of tap water, and add 2g of NaHCO 3 Soak at room temperature for 14 hours. Mix the soaked black soybeans with 800mL deionized water, grind them with hot water at 85°C, and pass through a 180-mesh sieve to obtain pure black soybean milk. Measure 600ml of black soybean milk, add 80U / g protein bromelain, and keep warm at 45°C for 5 minutes. Then boil it, add 30g of sucrose and 6g of glucose, and fully dissolve.

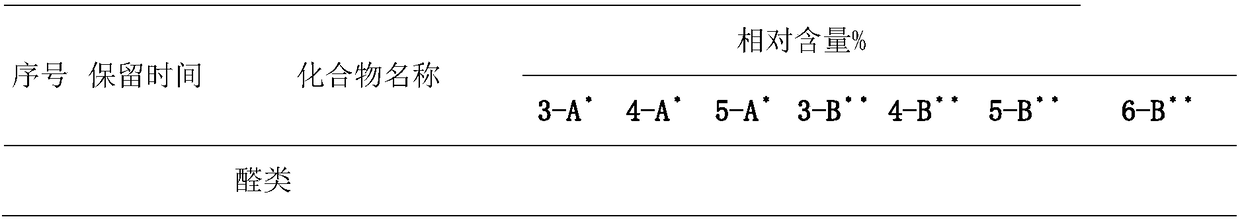

[0062] (2) The black soybean milk prepared above was subjected to normal homogenization treatment, and 400 mL was measured and placed in a 500 mL Erlenmeyer flask, and steamed at 100° C. for 15 min. Sampling and analysis of its volatile components.

[0063] (3) Measure 12ml of Streptococcus thermophilus ST3 seed culture solution and 12ml of L.casei-01 seed cultur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com