Enzyme-driven bottle-shaped nano-motor and preparation method thereof

A bottle-shaped, nano-technology, applied in the field of medical biomaterials, can solve the problems of poor biological practicability, difficult positioning and control, and toxic and side effects of bubble-driven motors, and achieve strong controllability, good biocompatibility, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

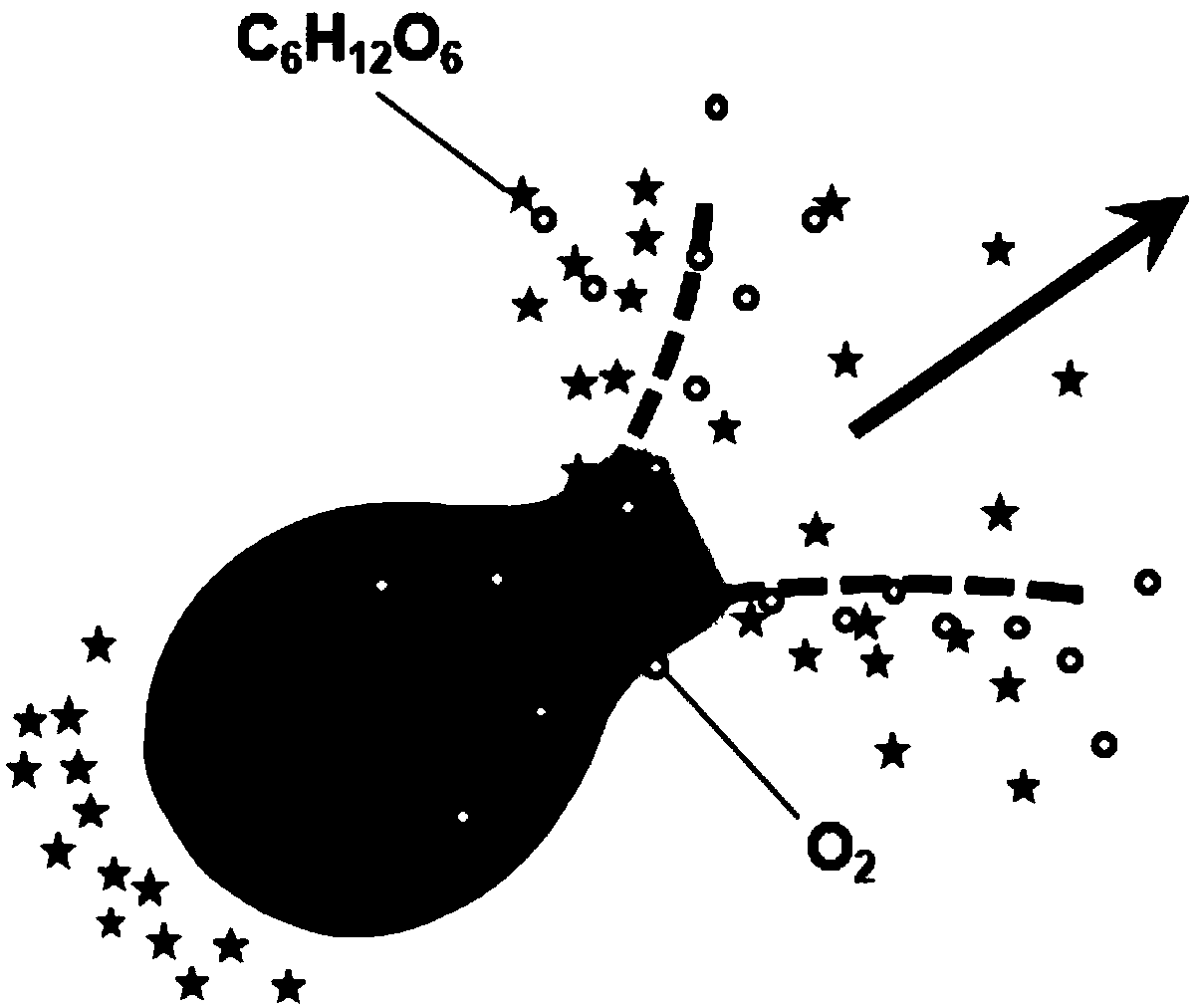

[0037] See figure 1 , figure 2 , image 3 ,

[0038] figure 1 It is the schematic diagram of the enzyme-driven bottle-shaped nanomotor swimming in this embodiment;

[0039] figure 2 It is an optical microscope photo of enzyme-driven bottle-shaped nanomotor moving under chemical drive in the present embodiment;

[0040] image 3 It is an optical microscope photo of the enzyme-driven bottle-shaped nanomotor chemotactic movement under the glucose concentration gradient prepared in this example.

[0041] This embodiment provides an enzyme-driven bottle-shaped nanomotor, which includes a bottle-shaped nanoparticle skeleton and two enzymes inside the skeleton. Wherein the bottle-shaped nanoparticles are hydrothermally carbonized carbon-based polymers, and the two enzymes are glucose oxidase and catalase. Moreover, the glucose oxidase and catalase used in this example are commercially available products, wherein the glucose oxidase can decompose glucose, convert the chemica...

Embodiment 2

[0049] See Figure 4 , Figure 5 ,

[0050] Figure 4It is a schematic diagram of step 3 and step 4 in the preparation method of the enzyme-driven bottle-shaped nanomotor in this embodiment;

[0051] Figure 5 It is a transmission electron microscope photo and an energy dispersive X-ray detection photo of the enzyme-driven bottle-shaped nanomotor prepared in this example.

[0052] In this example, using bottle-shaped nanoparticles, glucose oxidase, and catalase as materials, glucose oxidase and catalase are simultaneously loaded inside the bottle-shaped nanoparticles by vacuum infusion and ultrasonic infusion to prepare a Enzyme-driven bottle-shaped nanomotors. Specifically include the following steps:

[0053] Step 1. Preparation of bottle-shaped nanoparticles:

[0054] a. Add 0.0435g polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) and 0.0365g sodium oleate (SO) into 20mL deionized water to obtain mixed solution A, and Stir at 100rp...

Embodiment 3

[0070] In this example, using bottle-shaped nanoparticles, glucose oxidase, and catalase as materials, glucose oxidase and catalase are simultaneously loaded inside the bottle-shaped nanoparticles by vacuum infusion and ultrasonic infusion to prepare a Enzyme-driven bottle-shaped nanomotors. Specifically include the following steps:

[0071] Step 1. Preparation of bottle-shaped nanoparticles:

[0072] a. Add 0.0435g polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) and 0.0365g sodium oleate (SO) into 10mL deionized water to obtain mixed solution A, and Stir at a speed of 100rpm / min in a water bath at 25°C for 0.5h;

[0073] b. Dissolve 2g of ribose in 20mL of deionized water, add it to the mixed solution A, and stir in a water bath at a temperature of 25°C for 20min at a speed of 100rpm / min to obtain a mixed solution B;

[0074] c. Transfer the mixed solution B to a 75mL reaction kettle, put it in an oven, keep it at 160°C for 8-20h, and ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com