Preparation method of nano modified polypropylene board

A polypropylene sheet, nano-modification technology, applied in the field of preparation of nano-modified polypropylene sheet, can solve the problems of low impact strength, poor aging resistance, poor wear resistance, etc., to improve flame retardancy, enhance dispersion, Effect of increasing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

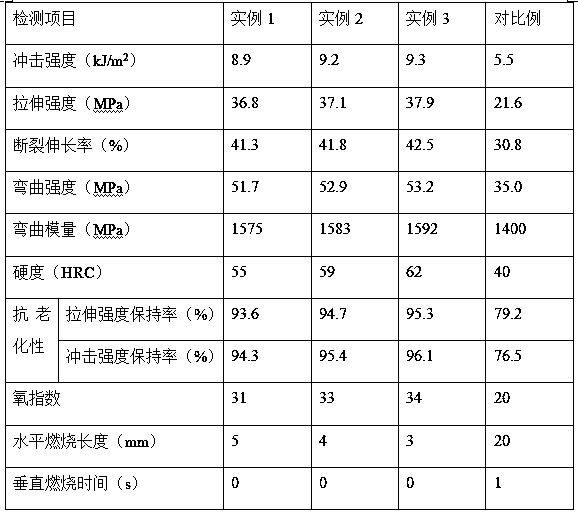

Examples

Embodiment Construction

[0024]Weigh 75-85g of polypropylene and heat up to 165-175°C to soften it, add 2-4g of antimony trioxide and 3-5g of red phosphorus to the softened polypropylene in turn, continue to keep warm and mix and stir for 35-45min to obtain Modified polypropylene melt; Weigh 11-13g sycamore leaves and place them in a beaker with 40-45mL deionized water, and place the beaker in an ultrasonic oscillator at a temperature of 65-70°C and a frequency of 10- Under the condition of 12kHz, ultrasonically extract for 16-20min, remove the filter residue by filtration, collect the filtrate, and distill the filtrate under reduced pressure for 8-10min to obtain the self-made plant extract. The extracts were mixed and placed in an ultrasonic disperser, and ultrasonically dispersed for 16-20 minutes under the conditions of power 85-100W and frequency 4-6kHz to obtain a modified polypropylene dispersion; measure 16-20mL butyl titanate and dissolve in Put in a beaker with 75-80mL of absolute ethanol an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com