Conductive anticorrosive coating using organic silver as light curing accelerator

A technology of conductive anti-corrosion and light curing agent, applied in the field of coatings, can solve the problems of insufficient conductivity and compactness, and difficulty in obtaining raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

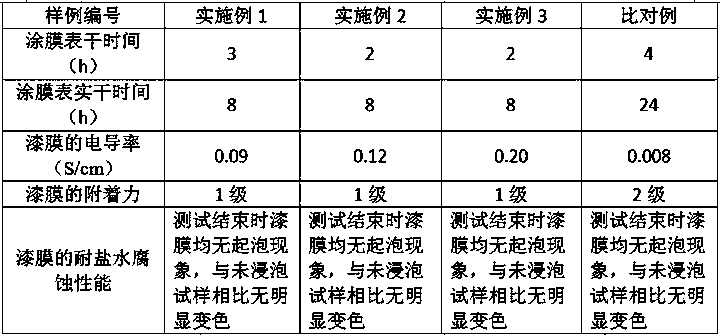

Embodiment 1

[0021] 15g of neoprene emulsion, 15ml of ethyl acetate, 6ml of butanol, 13g of surface-modified colloidal graphite, 32g of graphite powder with a surface-modified particle diameter of about 1 to 5 microns, 0.6g of organic bentonite, dispersed into Uniform slurry, 1 N-p-toluenesulfonylpyridine extracted Ag+ organic amine solution (containing 5% silver) 5ml was added and stirred for 15 minutes, the paint was painted on the steel sheet, and the performance test of the paint film coating was carried out after the film was formed and dried. .

Embodiment 2

[0023] 13g of perchlorethylene resin, 13ml of dibutyl carbitol, 6ml of butanol, 13g of surface-modified colloidal graphite, 36g of surface-modified graphite powder with a particle size of about 1-5 microns, 0.6g of organic bentonite, and disperse with high-speed grinding machine to disperse into a uniform slurry, add 5ml of organic amine solution (containing 8% silver) of 1 N-p-toluenesulfonylpyridine to extract Ag+ and stir evenly for 15 minutes, paint the paint on the steel sheet, and coat the paint film after the film is hard-dried Run performance tests.

Embodiment 3

[0025] 13g of perchlorethylene resin, 13ml of dibutyl carbitol, 6ml of butanol, 13g of surface-modified colloidal graphite, 36g of surface-modified graphite powder with a particle size of about 1-5 microns, 0.6g of organic bentonite, and disperse with high-speed grinding machine to disperse into a uniform slurry, add 5ml of organic amine solution (containing 12% silver) of N-p-toluenesulfonylpyridine to extract Ag+ and stir evenly for 15 minutes, paint on the steel sheet, and coat the paint film after the film is hard-dried Run performance tests.

[0026] Comparative example

[0027] 15g of acrylic epoxy resin, 15ml of ethyl acetate, 6ml of butanol, 13g of colloidal graphite, 32g of graphite powder with a particle size of about 1-5 microns, dispersed into a uniform slurry with a high-speed grinding disperser, and 5ml of polyethylene polyamine solution was added to stir Evenly for 15 minutes, brush the paint on the steel sheet, and perform a performance test on the paint film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com