Method for preparing BCZT-based leadless piezoelectric ceramics

A technology based on lead-free piezoelectric and ceramics, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of unstable work, lower Curie temperature of the system, health and survival Environmental hazards and other issues, to achieve the effect of increased filling density, increased Curie temperature, and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

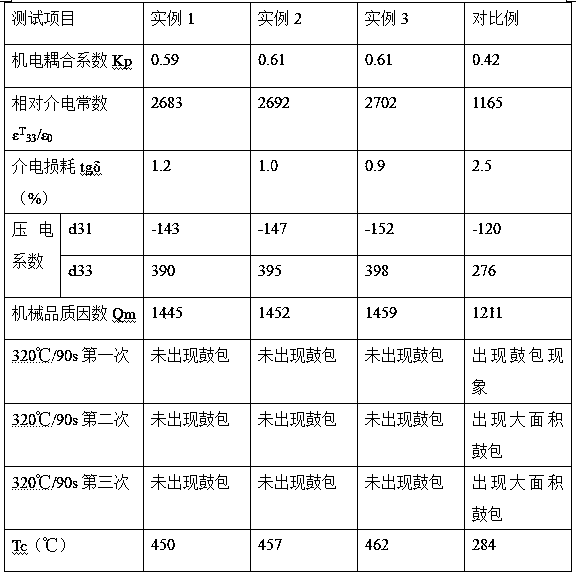

Examples

Embodiment Construction

[0024] In parts by weight, dissolve 3~4 parts of citric acid in 10~12 parts of ethylene glycol, heat to 80~90°C to obtain a mixed solution, and then use 0.5~1.0 part of tetrabutyl titanate for 5~ Diluted with 7 parts of absolute ethanol, add it to the mixed solution and stir for 2.0~2.5h to obtain a composite solution. After the composite solution is cooled to 40~50℃, continue to add 13 to 15 parts of 25% by mass to the composite solution. Barium acetate solution, stir and react for 1.0~1.5h, then add 3~4 parts of calcium nitrate solution with 10% mass fraction and 0.5~0.8 parts of zirconium nitrate solution with 20% mass fraction in sequence, and mix well to obtain BCZT-based polymer precursor The BCZT-based polymer precursor is placed in a blast dryer set at a temperature of 100~120℃, and dried for 7~8h to obtain BCZT-based gel. The BCZT-based gel is obtained in a muffle furnace at a temperature of 450~500℃. Base gel coking treatment for 4~5h to obtain black foam. Grind the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com