Modified soybean isolate protein blasting bead material and preparation method thereof

A technology for soybean protein and soybean protein isolate, applied in the fields of modified polymer materials, explosive bead materials and their preparation, can solve the problems of poor brittleness, easy moisture absorption, polluted cigarette holder interface, etc. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Disperse soybean protein isolate in 2.4mol / L urea solution under nitrogen atmosphere. Stir for 2 hours under the condition of 35° C. water bath, then raise the temperature to 85° C., react for 1 hour, adjust the pH to 8 with sodium hydroxide solution, and perform the soybean protein isolate activation treatment.

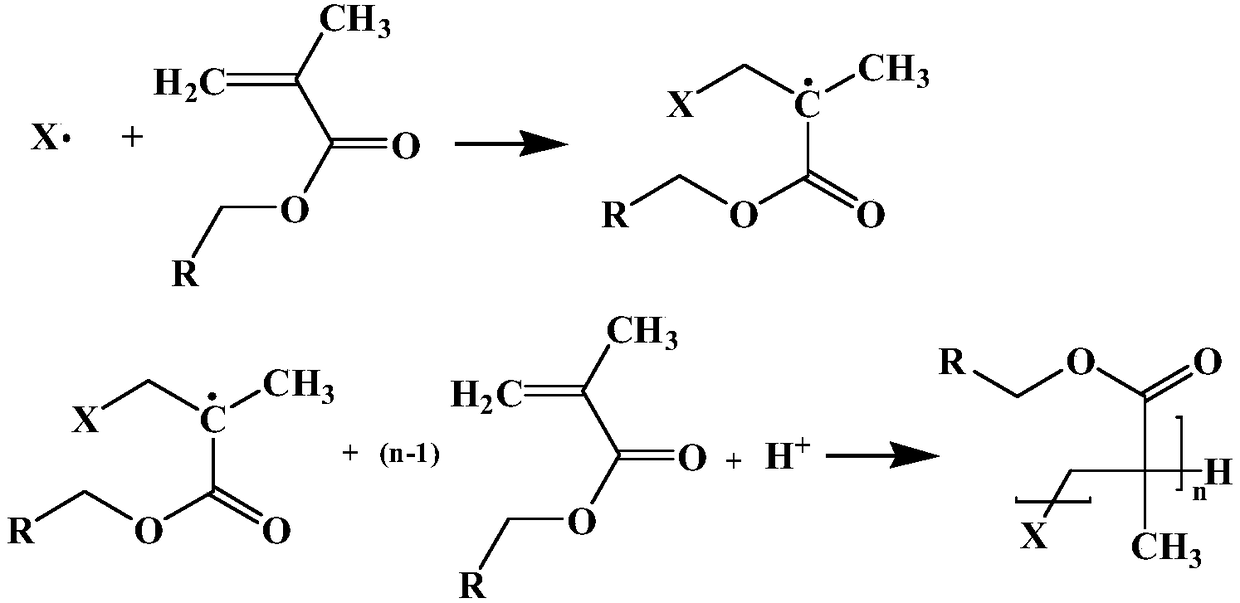

[0036] 2) Adjust the grafting reaction temperature to 70°C. After the temperature stabilizes, add ammonium persulfate and sodium bisulfite, stir for 10 minutes, add methyl methacrylate dropwise, and the grafting reaction time is 4 hours. A water-insoluble copolymerized product is generated, the product is removed, washed repeatedly, and vacuum-dried to complete the graft modification of soybean protein isolate.

[0037] 3) each component and mass ratio:

[0038] Modified soybean protein: 95 parts;

[0039] Butanediol: 2 parts;

[0040] Propylene glycol: 2 parts;

[0041] Antioxidant 1010: 0.7 parts;

[0042] Antioxidant 1076: 0.3 parts;

[0043] Mix a...

Embodiment 2

[0047] 1) Disperse soybean protein isolate in 3.5mol / L urea solution under nitrogen atmosphere. Stir for 1.5 h under the condition of 35° C. water bath, then raise the temperature to 85° C., react for 1.5 h, adjust the pH to 8 with sodium hydroxide solution, and perform the soybean protein isolate activation treatment.

[0048] 2) Adjust the grafting reaction temperature to 75°C. After the temperature is stable, add potassium persulfate and anhydrous sodium sulfite, stir for 10 minutes, add the grafting monomer methyl methacrylate dropwise, and the grafting reaction time is 5 hours. 2% hydroquinone is added dropwise to terminate the reaction, and a water-insoluble copolymer product is generated. The product is removed, washed repeatedly, and vacuum-dried to complete the graft modification of soybean protein isolate.

[0049] 3) each component and mass ratio:

[0050] Modified soybean protein: 98 parts;

[0051] Sorbitol: 1 part;

[0052] Antioxidant 264: 0.7 parts;

[0053...

Embodiment 3

[0056] 1) Disperse soybean protein isolate in 8mol / L urea solution under nitrogen atmosphere. Stir for 1 hour under the condition of 35° C. water bath, then raise the temperature to 80° C., react for 2 hours, adjust the pH to 8 with sodium hydroxide solution, and perform the soybean protein isolate activation treatment.

[0057] 2) Adjust the grafting reaction temperature to 80°C. After the temperature stabilizes, add ammonium cerium sulfate, stir for 10 minutes, and add the grafting monomer ethyl methacrylate dropwise. The grafting reaction time is 3 hours. A water-insoluble copolymerized product is generated, the product is removed, washed repeatedly, and vacuum-dried to complete the graft modification of soybean protein isolate.

[0058] 3) each component and mass ratio:

[0059] Modified soybean protein: 96 parts;

[0060] Polyethylene glycol: 1 part;

[0061] Propylene glycol: 1 part

[0062] Glycerin: 0.5 part;

[0063] Antioxidant 1010: 0.5 parts;

[0064] Antioxi...

PUM

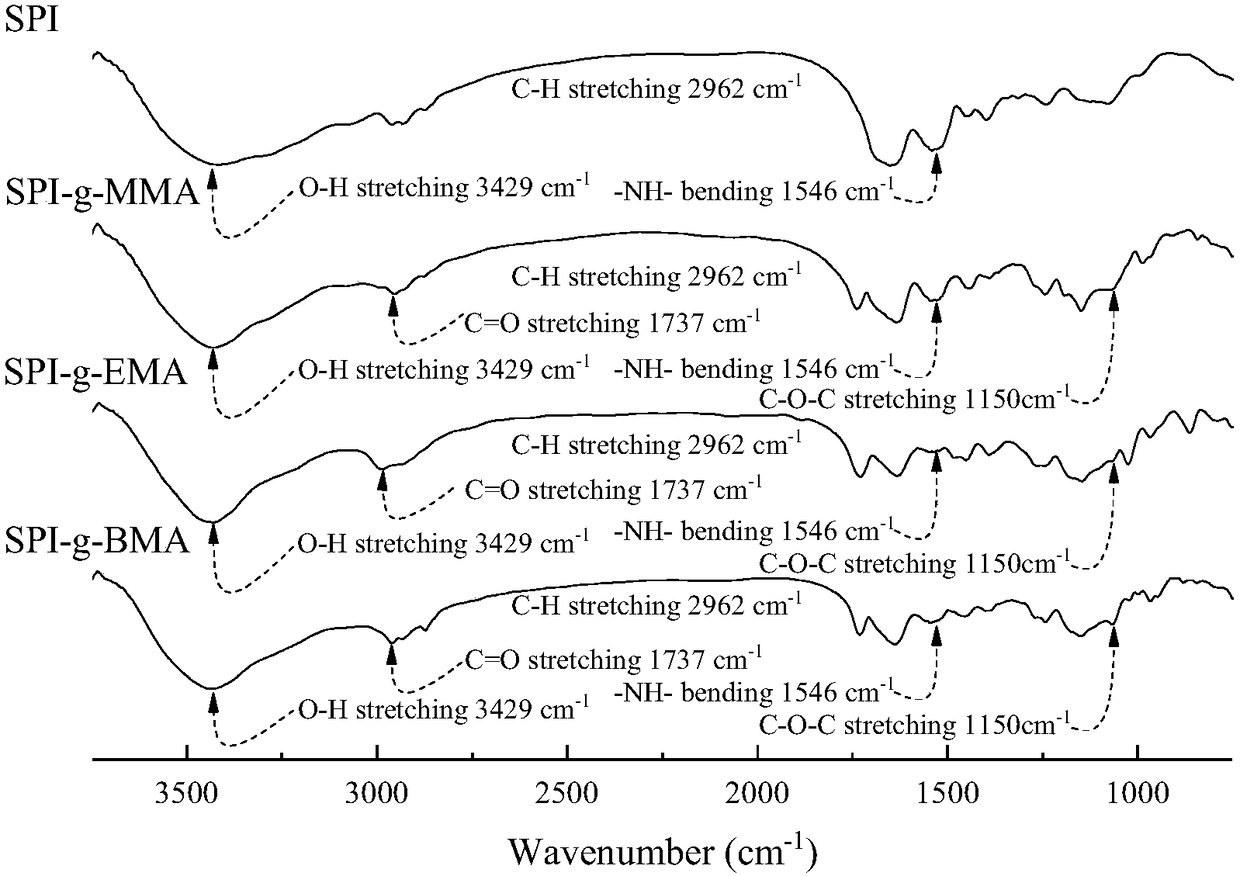

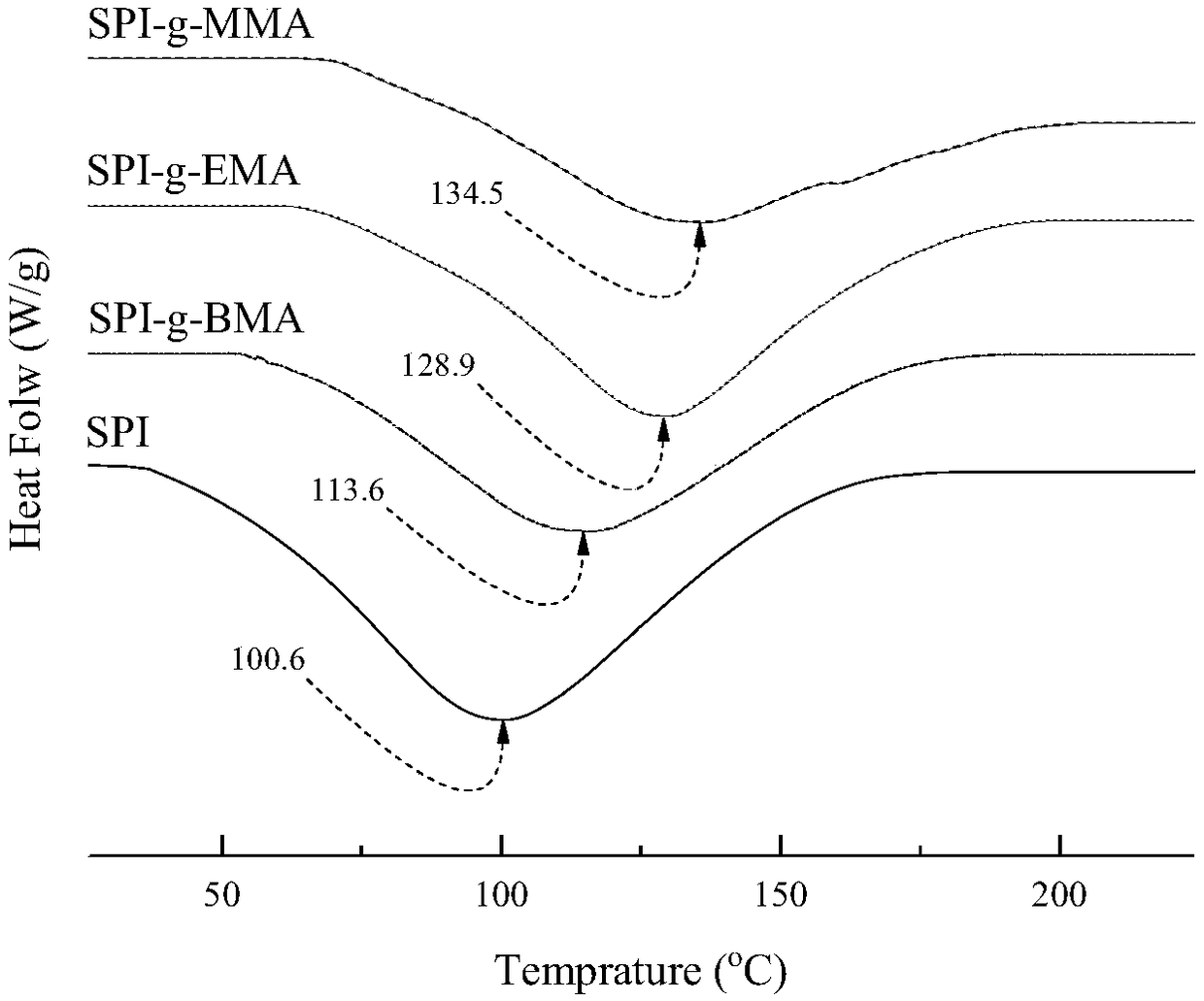

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com