Method for preparing high-capacity battery anode material

A battery negative electrode and electrode material technology, applied in the field of materials science, can solve the problems of poor rate performance and low electrochemical performance, and achieve the effects of increased rate performance, increased diffusion rate, and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

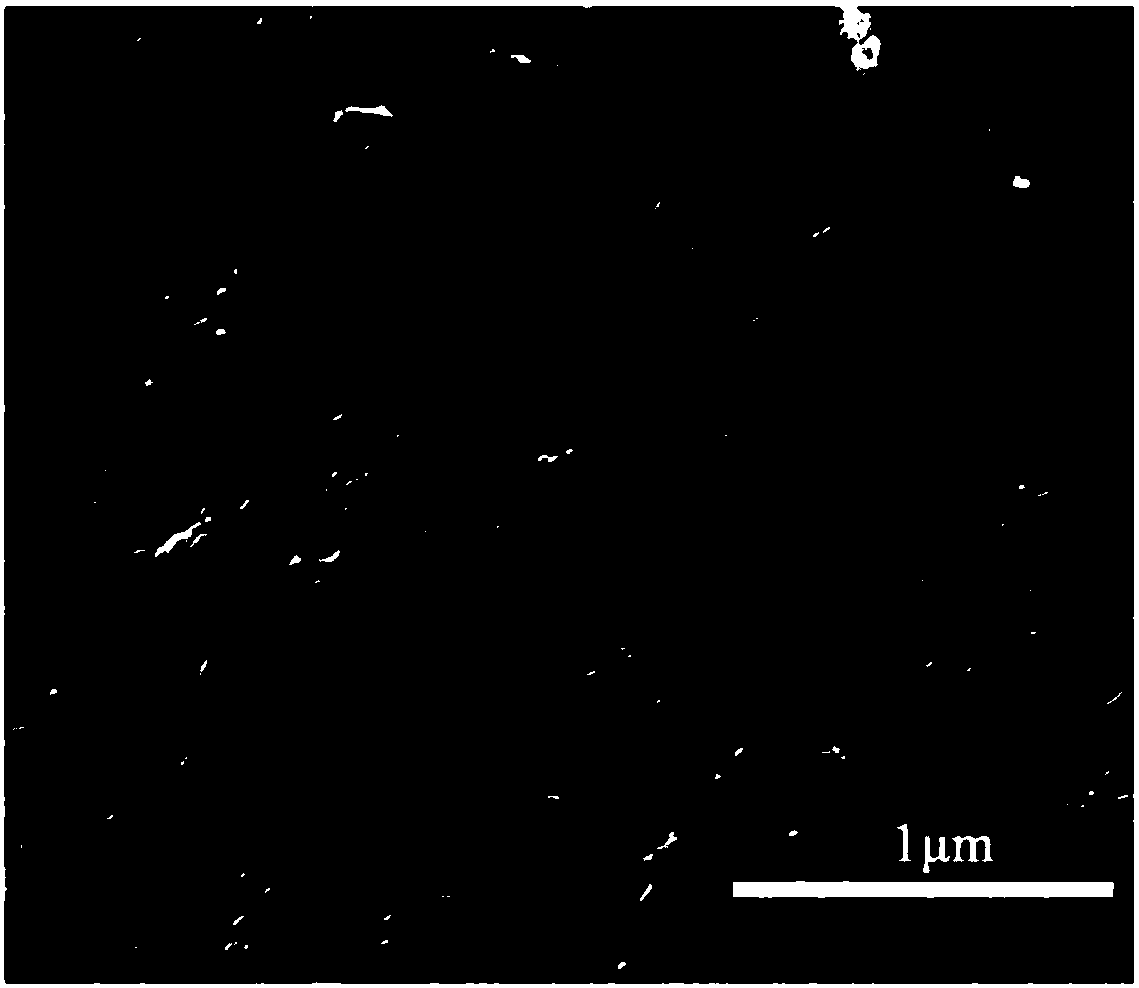

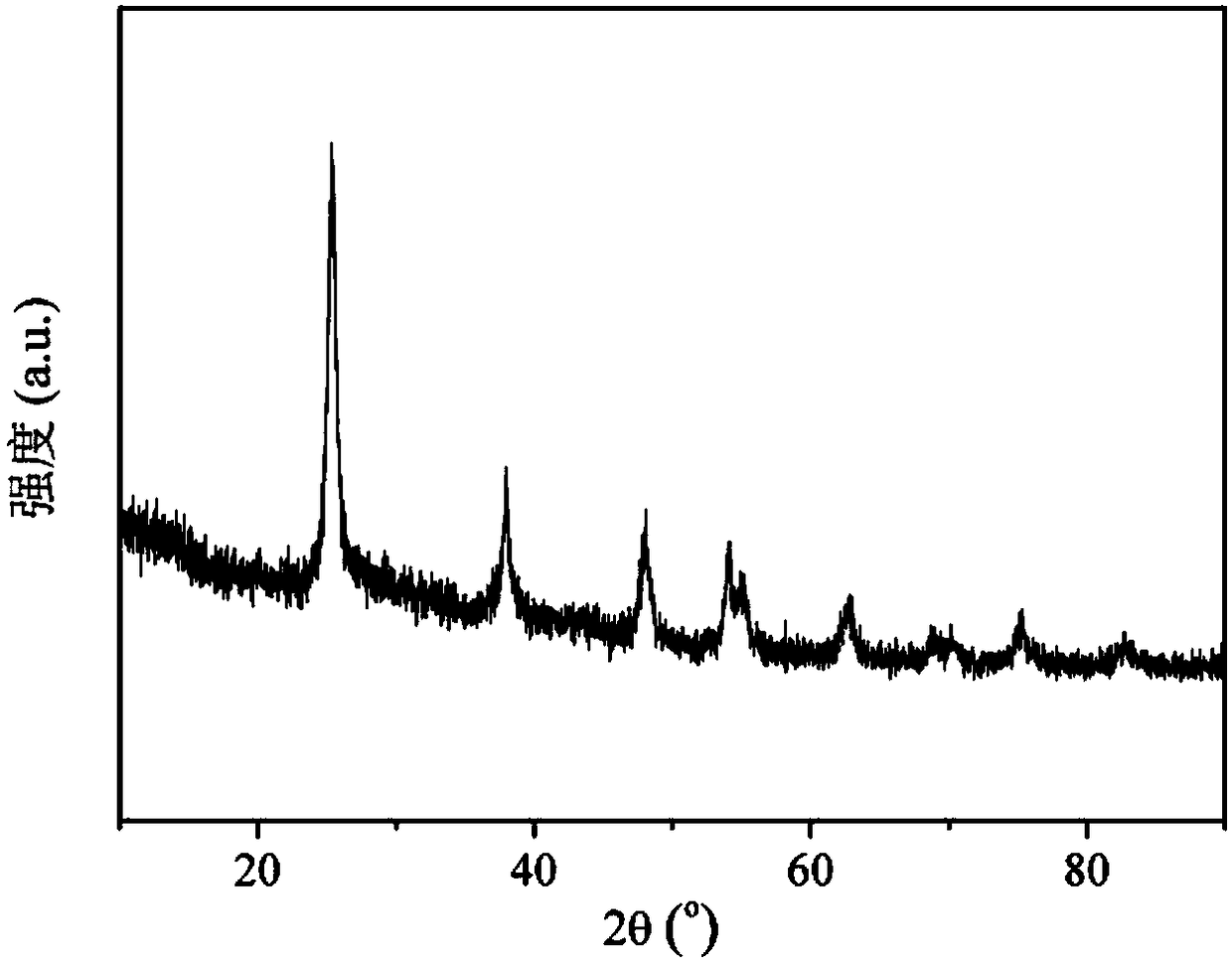

[0035] The prepared metal oxide material with high-performance three-dimensional carbon nanotubes as the skeleton, the structural test of the material and the electrochemical performance test of the assembled lithium-ion simulated battery.

[0036] 1) Disperse 0.12g of oxidized multi-walled carbon nanotubes in 20mL of deionized water, sonicate for 30min to disperse evenly, then add 0.1mL of pyrrole liquid, and continue sonicating for 30min to obtain a dispersed suspension;

[0037] 2) Transfer the dispersed oxidized multi-walled carbon nanotube solution to a 75mL polytetrafluoroethylene liner, put it into a reaction kettle, and react at 180°C for 24h to obtain a gel-like nitrogen-rich carbon nanotube, and then freeze-dry 48h, obtain nitrogen-rich carbon nanotube aerogel;

[0038] 3) Add 5.68 g of titanium tetraisopropoxide solution into 5 mL of isopropanol, disperse it evenly by ultrasonication for 30 minutes, then add multi-walled carbon nanotube aerogel, and fully infiltrate...

Embodiment 2

[0044] The prepared metal oxide material with high-performance three-dimensional carbon nanotubes as the skeleton, the structural test of the material and the electrochemical performance test of the assembled lithium-ion simulated battery.

[0045] 1) Disperse 0.12g of oxidized multi-walled carbon nanotubes in 20mL of deionized water, sonicate for 30min to disperse evenly, then add 0.1mL of pyrrole liquid, and continue sonicating for 30min to obtain a dispersed suspension;

[0046] 2) Transfer the dispersed carbon dioxide multi-wall nanotube solution to a 75mL polytetrafluoroethylene liner, put it in a reaction kettle, and react at 180°C for 24h to obtain a gel-like nitrogen-rich carbon nanotube, and then freeze-dry 48h, obtain nitrogen-rich carbon nanotube aerogel;

[0047] 3) 5.4g of FeCl 3 ·6H 2 O solution was added to 5 mL of deionized water, ultrasonically dispersed for 30 minutes to make it evenly dispersed, and then carbon nanotube aerogel was added to fully infiltrat...

Embodiment 3、 Embodiment 4

[0053]

[0054]

[0055] Referring to the method of Example 1 or Example 2 according to the above experimental parameters, 0.02 mol corresponding metal oxide electrode materials with high-performance three-dimensional carbon nanotubes as the skeleton can be obtained respectively.

[0056] The metal oxide material of the present invention uses nitrogen-containing carbon nanotubes as the carbon skeleton. During the high-temperature crystallization process, N atoms combine with C and metal atoms to form an electron cloud, so that the self-assembled metal oxide on the carbon skeleton The material has excellent electrochemical properties, and has the advantages of environmental friendliness, simplicity, high yield, good controllability, etc., and is suitable for large-scale industrial production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com