Self-dry type waterborne alkyd resin and preparation method thereof

A water-based alkyd resin, self-drying technology, used in coatings, polyester coatings, etc., can solve the problems of poor heat resistance, slow drying speed, etc., and achieve good stability, good impact resistance, and quick-drying paint film. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

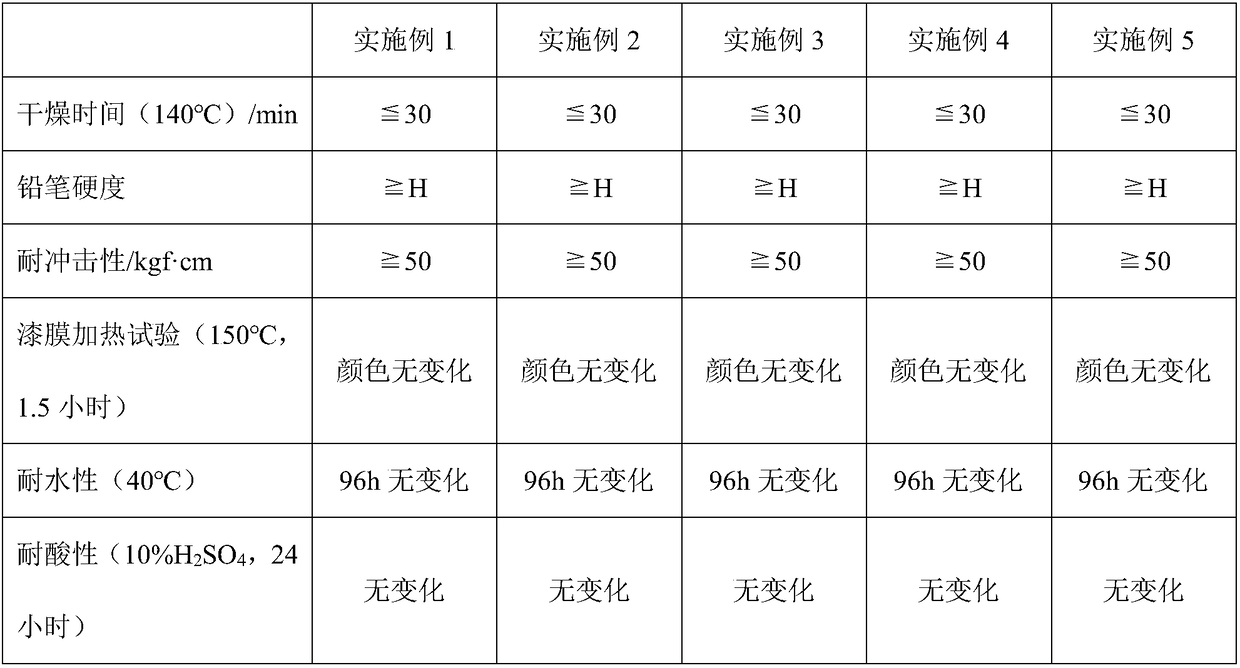

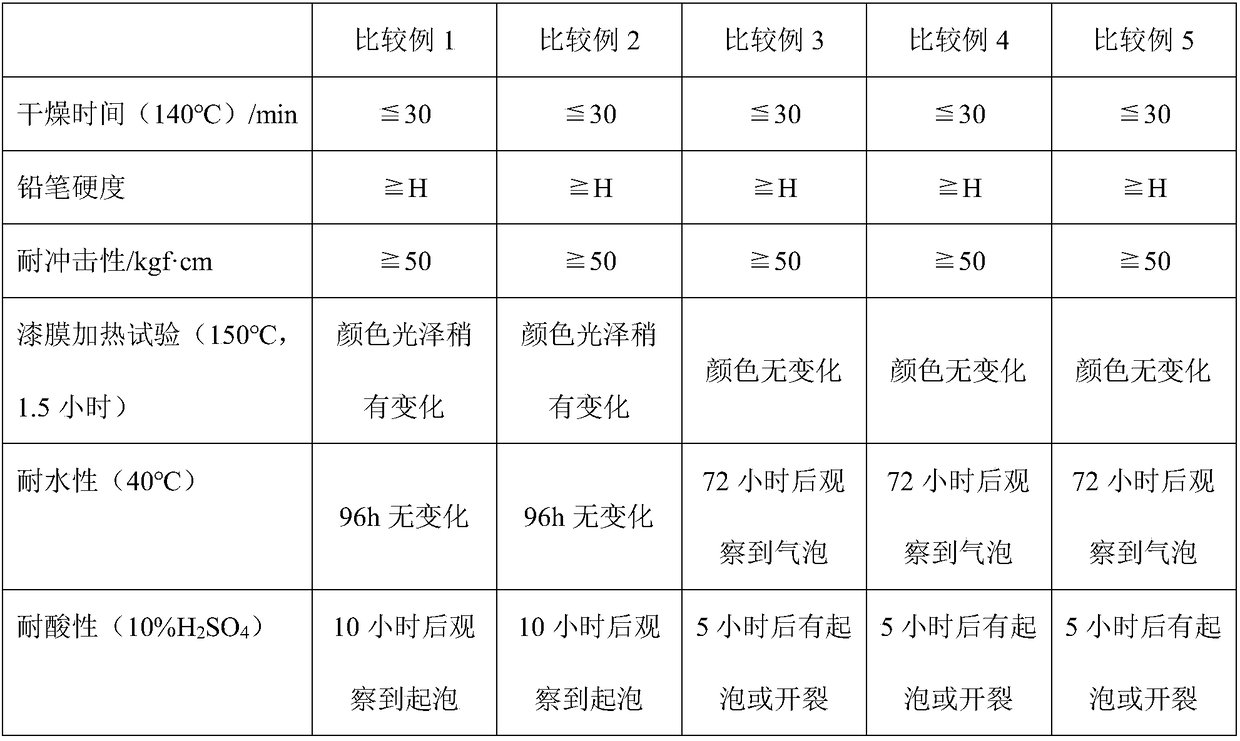

Examples

Embodiment 1

[0026] The raw materials of this embodiment are: coconut oleic acid: 20wt%, neopentyl glycol: 12wt%, trimethylolpropane: 13wt%, isophthalic acid: 8wt%, diethylene glycol isophthalate-5 - Sodium sulfonate: 5 wt%, glycidyl methacrylate: 3.0 wt%, organofunctional silica: 3.0 wt%, triethylamine: 5.0 wt%, ethylene glycol monobutyl ether: the balance.

[0027] Add coconut oleic acid, neopentyl glycol and trimethylolpropane to a four-necked flask equipped with a thermometer, a stirrer, a condenser and a thermocouple, raise the temperature to 150°C and start stirring, and slowly raise the temperature (below 5°C / min) Heat the reaction at 220°C, stop heating when the acid value is less than 10mgKOH / g; add isophthalic acid, diethylene glycol isophthalate-5-sulfonate, methacrylic acid when the temperature drops to 150°C Glycidyl esters and organofunctional silica, N-passed 2 , Stir and gradually heat up to 200°C and keep warm for reaction. When the acid value is 45-60mgKOH / g, stop heatin...

Embodiment 2

[0029] The raw materials of this embodiment are: linoleic acid: 18wt%, ethylene glycol: 4wt%, neopentyl glycol: 10wt%, trimethylolpropane: 12wt%, isophthalic acid: 8wt%, isophthalic acid Sodium diethylene glycol ester-5-sulfonate: 5 wt%, glycidyl methacrylate: 3.0 wt%, organofunctional silica: 3.0 wt%, triethylamine: 4.0 wt%, ethyl acetate: 8 wt% %, ethylene glycol monobutyl ether: balance.

[0030] In a four-neck flask equipped with a thermometer, stirrer, condenser and thermocouple, add linoleic acid, ethylene glycol, neopentyl glycol and trimethylolpropane, raise the temperature to 150°C and start stirring, slowly heat up (5°C / min) to 220°C for heat preservation reaction, when the acid value is less than 10mgKOH / g, stop heating; when the temperature drops to 150°C, add isophthalic acid, diethylene glycol isophthalate-5-sodium sulfonate , glycidyl methacrylate and organofunctionalized silica, N 2 , stir and gradually heat up to 200°C and keep warm for reaction. When the a...

Embodiment 3

[0032]The raw materials of this embodiment include: soybean oil fatty acid: 25wt%, diethylene glycol: 8wt%, neopentyl glycol: 8wt%, trimethylolpropane: 12wt%, 2,6-naphthalene dicarboxylic acid: 6wt%, Diethylene glycol isophthalate-5-sodium sulfonate: 3 wt%, Glycidyl methacrylate: 5.0 wt%, Organofunctional silica: 5.0 wt%, Triethylamine: 3.5 wt%, Acetic acid Isobutyl ester: 10 wt%, diethylene glycol monobutyl ether: balance.

[0033] In a four-neck flask equipped with a thermometer, a stirrer, a condenser and a thermocouple, add soybean oil fatty acid, diethylene glycol, neopentyl glycol and trimethylolpropane, raise the temperature to 150°C and start stirring, and slowly heat up (5 ℃ / min) to 220℃ for heat preservation reaction, when the acid value is less than 10mgKOH / g, stop heating; when the temperature drops to 150℃, add 2,6-naphthalene dicarboxylic acid, diethylene glycol isophthalate-5 -Sodium sulfonate, glycidyl methacrylate and organofunctional silica, N-passed 2 , st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com