Double-layer jam sour-milk and production technology thereof

A production process and jam technology, which is applied in the fields of milk preparations, food science, dairy products, etc., can solve the problems of less jam flavor and inability to adjust the degree of jam flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

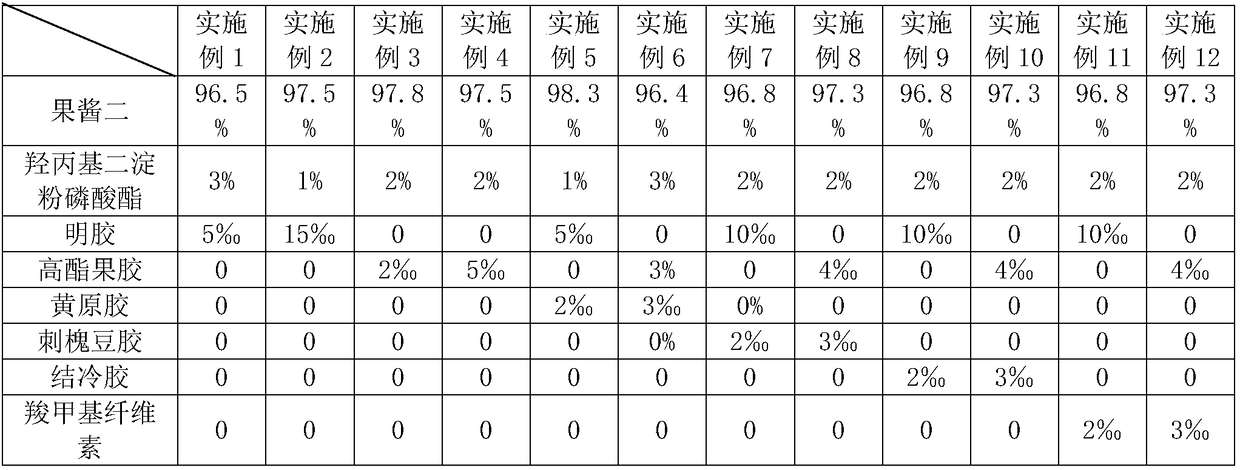

[0029] Embodiment 1: A double-layer jam yogurt, comprising an upper base material layer and a lower jam layer. The base material layer includes yogurt and fruit material, and the fruit material is jam. The jam layer is jelly-like, and the components and contents in the raw materials of the jam layer are shown in Table 1, and the contents of each component in Table 1 are mass ratios.

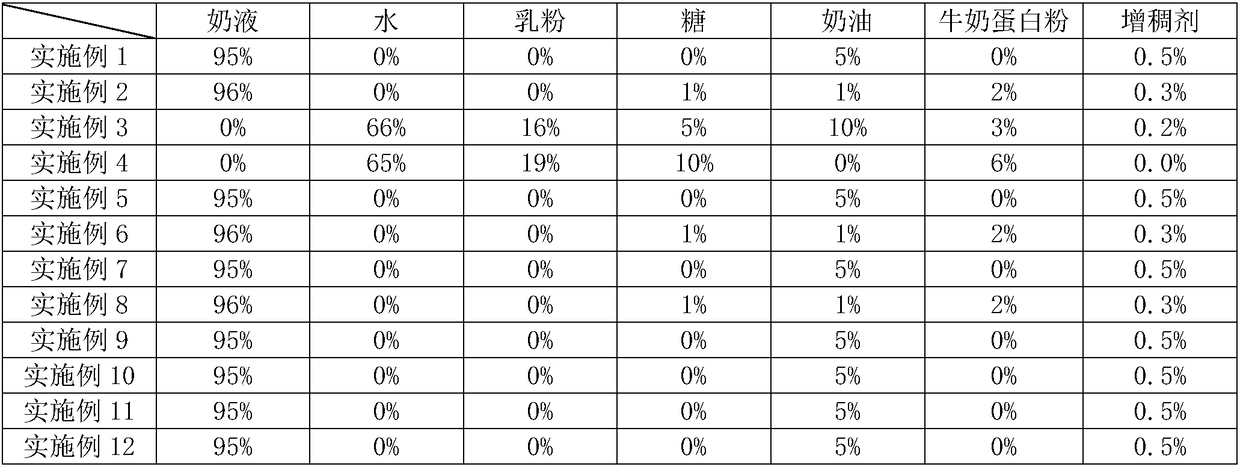

[0030]The production process of double-layer jam yoghurt includes the following steps, step (1) chemical material, heating the milk liquid to 60-80 ℃, putting in sugar, cream, milk protein powder, thickener, cutting for 5 minutes, and obtaining the material; material The mass ratio of each component in is as shown in table 2, and thickening agent is agar; Step (2) constant volume, standardization, the material importing batching tank of step (1), constant volume, carry out standardization, control temporary storage temperature 4 -18°C; step (3) homogeneous sterilization, heat exchange the materi...

Embodiment 2

[0031] Embodiment 2: A double-layer jam yogurt, comprising an upper base material layer and a lower jam layer. The base material layer includes yogurt and fruit material, and the fruit material is jam. The jam layer is jelly-like, and the components and contents in the raw materials of the jam layer are shown in Table 1, and the contents of each component in Table 1 are mass ratios.

[0032] The production process of double-layer jam yogurt includes the following steps. Step (1) Chemical material, heating the milk liquid to 60-80°C, putting in sugar, cream, milk protein powder, thickener, cutting for 15 minutes, and obtaining the material; material The mass ratio of each component in is as shown in table 2, and thickener is gelatin; Step (2) constant volume, standardization, the material of step (1) is imported batching tank, constant volume, carry out standardization, control temporary storage temperature 4 -18°C; step (3) homogeneous sterilization, heat exchange the materia...

Embodiment 3

[0033] Embodiment 3: A double-layer jam yogurt, the difference from Example 1 is that the components and contents in the jam layer raw materials are shown in Table 1, and the contents of each component in Table 1 are mass ratios.

[0034] In the production process of double-layer jam yogurt, step (1) heat water to 40-50°C, put in milk powder, cut for 5 minutes, hydrate for 25 minutes, then heat up to 60°C, put in sugar, cream, milk protein powder, thicken agent, cut for 5min to obtain the material, the ratio of each component in the material is as shown in Table 2, and the thickener is pectin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com