Preparation of copper sulfide/bismuth vanadate double-layer film composite and its application as photoanode

A composite material, bismuth nitrate pentahydrate technology, applied in the field of preparation of CuS/BiVO4 double-layer film composite material, to achieve the effects of reducing recombination, good conductivity, and improving photoelectrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

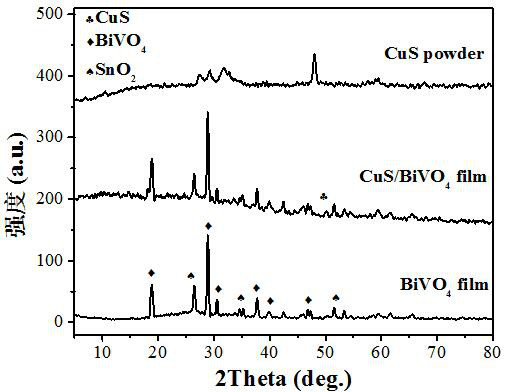

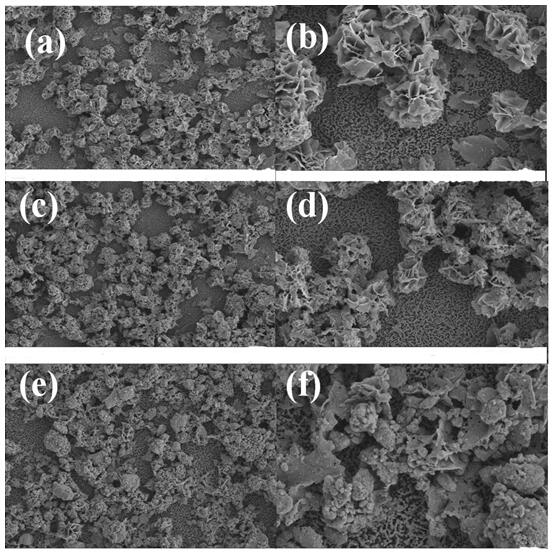

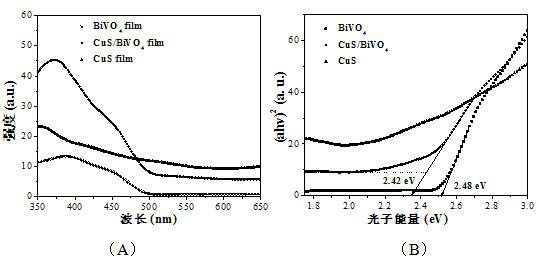

[0026] The present invention will be described below for CUS / BIVO 4 The preparation, performance and application of the double membrane further illustrates.

[0027] First, CUS / BIVO 4 Double film preparation

[0028] (1) Preparation of flower CUS

[0029] 2.046 g of copper chloride (Cucl 2 · 2h 2 O), 1.827 g of thiourea was dissolved in 28 ml of secondary distilled water and 14 ml unhydrate ethanol mixture. Then put CUCL 2 · 2h 2 O solutions were slowly added to the thiourea solution, and all the solution was added to the solution, and the suspension at this time was stirred at room temperature for 30 min. The reaction liquid after the stirring was transferred to 100 ml of polytetrafluoroethylene liner, 140 ° C heating 12 h, after completion of the reaction, naturally cooled to room temperature to give the ink green precipitate. The resulting precipitate was centrifuged, and the dried water was washed several times, and 6 h was dried at 60 ° C for several distilled water.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com