A solid welding process for heat dissipation chips

A welding process and chip body technology, applied in welding equipment, electrical solid devices, manufacturing tools, etc., can solve the problems of high void rate and a large number of voids in chip bonding, reduce void rate, eliminate voids, and improve inherent reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

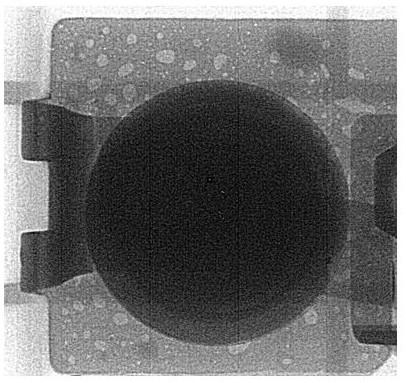

[0040] Refer to attached Image 6 Shown, the technology in the present embodiment is as follows:

[0041] The first step is to select the chip body 1 and the first heat dissipation device that matches the chip body 1; there can be one or more first heat dissipation devices. In this embodiment, there is one first heat dissipation device. When it is placed, It can be arranged on any side of the chip body 1 .

[0042] The second step is to install the heat dissipation chip; specifically, place the chip body 1 and the first heat dissipation device in the sealed cabin of the hot isostatic press at the same time, and perform vacuuming operation on the sealed cabin; Injecting an inert gas, using a hot isostatic pressing process to connect the chip body 1 to the first heat sink in a solid phase;

[0043] In the hot isostatic pressing process, the heating temperature is 0.3-0.8 times the melting point temperature of the first heat sink.

[0044]In this embodiment, the heating temper...

Embodiment 2

[0051] Refer to attached Figure 6-7 As shown, the present invention discloses a solid welding process for a heat dissipation chip. In this embodiment, the chip body 1 is provided with first heat dissipation devices above and below, and the first heat dissipation devices are respectively a first heat dissipation plate 4 and a second heat dissipation plate. Radiating plate 5.

[0052] Specifically include the following steps:

[0053] The first step, the formation of the first heat dissipation device: the chip body 1, the first metal sheet 2, the first heat dissipation plate 4 and the second heat dissipation plate 5, the finished chip is arranged according to the first heat dissipation plate 4, the first metal sheet from top to bottom 2. The chip body 1 , the second metal sheet 3 and the second heat dissipation plate 5 are stacked in order to form a chip with the first heat dissipation device.

[0054] In this embodiment, a metal sheet is disposed between the first heat dissi...

Embodiment 3

[0064] In this embodiment, a solid welding process for a heat dissipation chip, in this embodiment, there are four heat dissipation devices, the first heat dissipation plate 4, the second heat dissipation plate 5, the copper electrode sheet 6 and the copper base 7, and its layers are arranged on The upper and lower surfaces of the chip body 1 are provided with two types of heat dissipation devices on the upper surface and the lower surface of the chip body 1 respectively in this embodiment in order to improve the heat dissipation effect.

[0065] This embodiment specifically includes the following processes:

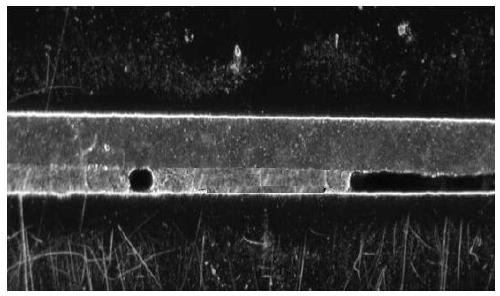

[0066] The first step, pretreatment of the chip body 1: performing impurity removal on the chip body 1;

[0067] Specifically, the chip body 1 is thinned to 270um-360um, the upper and lower surfaces of the chip body 1 are respectively polished, and at the same time, the upper and lower surfaces of the chip are bombarded by a plasma machine for 2 minutes to complete the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com