Method for processing sludge

A sludge and mud cake technology is applied in the field of joint treatment of sludge with modified aluminum ash and acetic acid, which can solve the problems of poor economy, complicated operation, and high energy consumption, and achieve good economy, simple production process, and energy efficiency. costly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

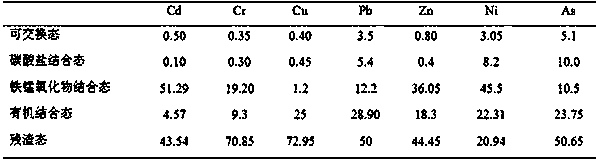

Embodiment 1

[0022]Embodiment 1: the method for this processing sludge, concrete operation is as follows:

[0023] (1) Weigh 0.1g of cetyltrimethylammonium bromide (relative molecular weight 364.45) and 0.1g of octadecyldimethylbenzyl ammonium chloride (relative molecular weight 424.15), add 100mL of deionized water, mix After homogenization, place the mixed solution in a shaker for 2 hours at normal temperature. After the reaction is completed, a homogeneous mixed solution of the two is obtained, which is stored in a brown reagent bottle for later use. Cetyltrimethylammonium bromide and octadecyl ammonium The total molar concentration of alkyl dimethyl benzyl ammonium chloride in the homogenate is 5mmol / L;

[0024] (2) Add 100mL homogeneous solution with a concentration of 5mmol / L to 10g of industrial aluminum ash, react in a mixing and stirring reactor at 20°C for 3h, filter and wash the solid-liquid mixture with distilled water at 0.025MPa, repeat 3 times , the solid is placed in a des...

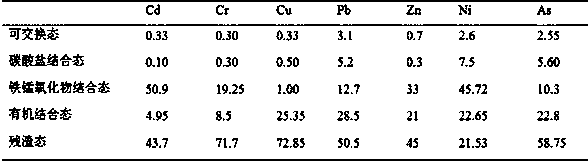

Embodiment 2

[0032] Embodiment 2: the method for this processing sludge, concrete operations are as follows:

[0033] (1) Weigh cetyl trimethyl ammonium bromide and octadecyl dimethyl benzyl ammonium chloride, add deionized water, mix well and place the mixture in a shaker at room temperature Shake for 3 hours to obtain a homogeneous mixture, which is stored in a brown reagent bottle for later use, wherein the total molar concentration of cetyltrimethylammonium bromide and octadecyldimethylbenzyl ammonium chloride in the homogeneous mixture is 10mmol / L, the mass ratio of cetyl trimethyl ammonium bromide and octadecyl dimethyl benzyl ammonium chloride is 4:1;

[0034] (2) Add 300mL of a homogenized solution with a concentration of 10mmol / L to 10g of industrial aluminum ash, react in a mixing and stirring reactor at 30°C for 3h, filter and wash the solid-liquid mixture with distilled water at 0.04MPa, repeat 3 times The second time, the solid is placed in a desiccator and dried at 110°C fo...

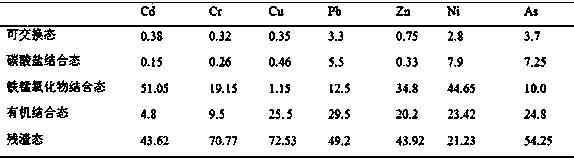

Embodiment 3

[0042] Embodiment 3: the method for this processing sludge, concrete operations are as follows:

[0043] (1) Weigh cetyl trimethyl ammonium bromide and octadecyl dimethyl benzyl ammonium chloride, add deionized water, mix well and place the mixture in a shaker at room temperature Shake for 3 hours to obtain a homogeneous mixture, which is stored in a brown reagent bottle for later use, wherein the total molar concentration of cetyltrimethylammonium bromide and octadecyldimethylbenzyl ammonium chloride in the homogeneous mixture is 20mmol / L, the mass ratio of cetyl trimethyl ammonium bromide and octadecyl dimethyl benzyl ammonium chloride is 3:1;

[0044] (2) Add 500mL of a homogenized solution with a concentration of 20mmol / L to 10g of industrial aluminum ash, react in a mixing and stirring reactor at 25°C for 6h, filter and wash the solid-liquid mixture with distilled water at 0.04MPa, repeat 2 Second, the solid is placed in a desiccator and dried at 100°C for 3 hours to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com