Film-grade nylon 6 pellets and production method thereof

A production method and slicing technology, applied in the field of nylon 6 industrial production, can solve the problems of affecting storage and transportation, general filtration effect, prone to crystal point and membrane rupture, etc., and achieve high quality, avoid crystal point and membrane rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

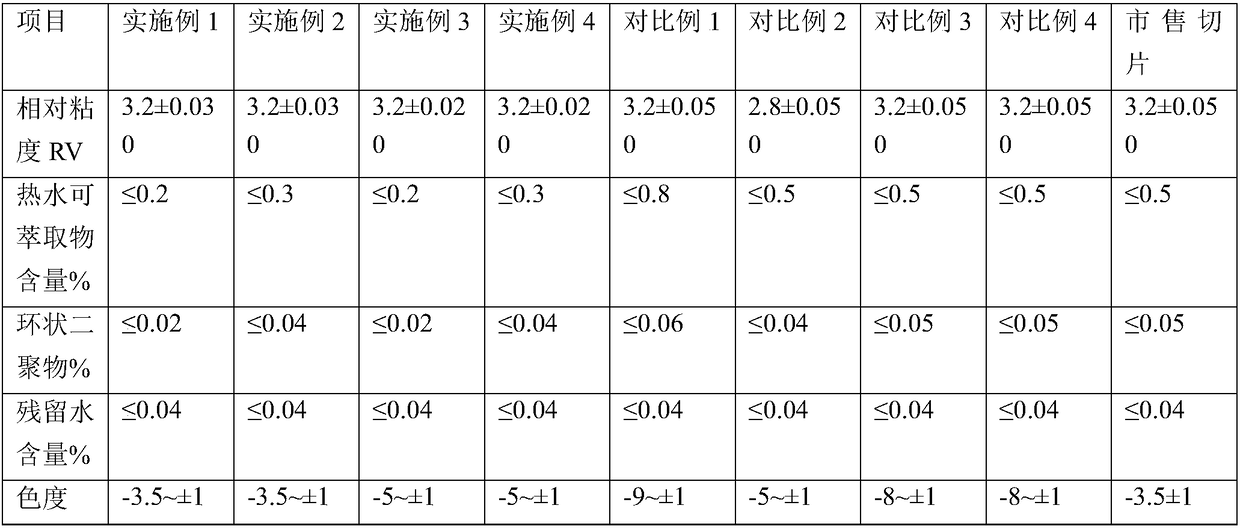

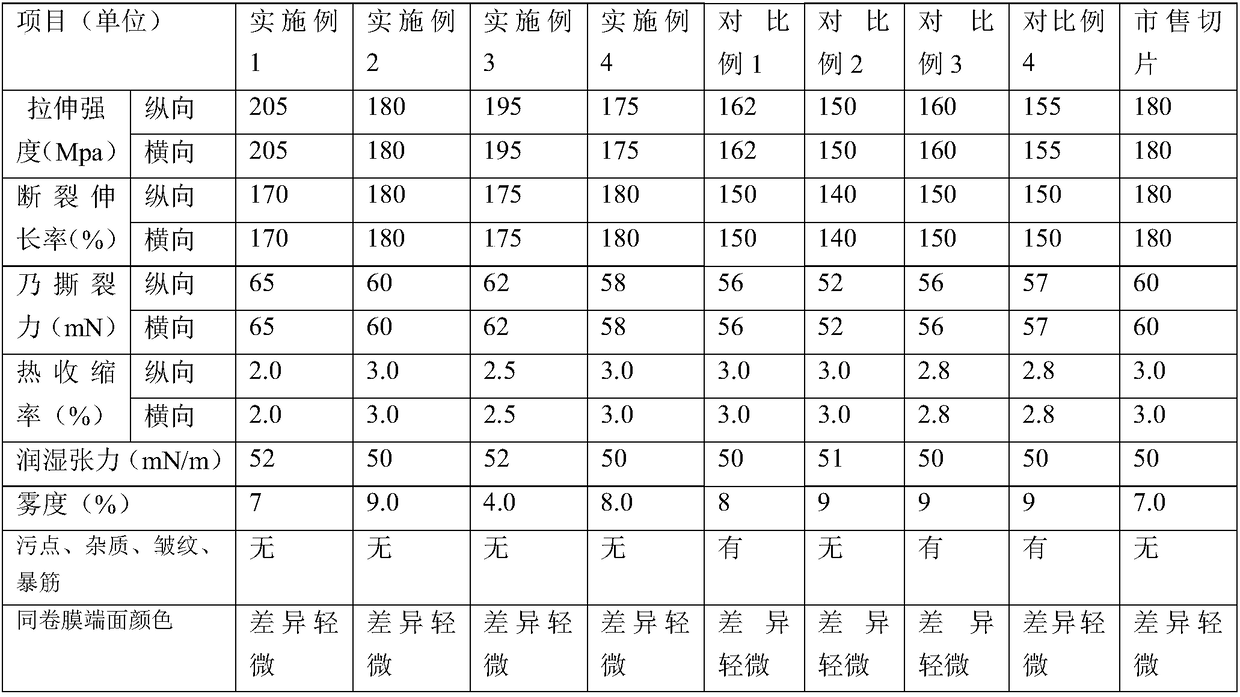

Examples

Embodiment 1

[0035] The production method of membrane-grade nylon 6 chips comprises the following steps:

[0036] Step 1): crush the solid caprolactam and heat it to melt to obtain fresh caprolactam and send it to a large caprolactam storage tank; add 50% by weight of solid caprolactam to the extraction concentrate, stir and dissolve in the purification tank, and pump the external Circulation, the circulation system is equipped with a steam heat exchanger for heating, and a filter with a pressure difference alarm device is installed at the outlet of the pump to control the heating temperature of the steam heat exchanger to 120°C, and the pressure difference alarm device controls the pressure at 50kpa. A packed tower is installed on the top to remove moisture by condensation and reflux, and the water content of the mixture coming out of the purification kettle is controlled at 5% by weight, and the caprolactam content is 90% by weight. into the large storage tank of caprolactam; the homogen...

Embodiment 2

[0044] The preparation process of membrane-grade nylon 6 chips is the same as in Example 1, the difference is that step 1) adds 70% by weight of solid caprolactam to the extraction concentrate, the temperature heated by the steam heat exchanger is 140° C., and the differential pressure alarm device controls the pressure at 45-55kpa, the purified mixture is obtained from the purification kettle, the mixture from the purification kettle: the mass ratio of fresh caprolactam is 1:2, and sent to the large caprolactam storage tank to obtain liquid A, and the additives include 1% of the total weight of liquid A Chain terminator benzoic acid, the conventional nucleating agent accounting for 1% of the total weight of liquid A, and the anti-blocking agent active titanium dioxide accounting for 1% of the total weight of liquid A; the preheater is heated to 150°C in step 2), and the resulting material is sent to cracking Reactor, at 230 DEG C, under 200kpa, the material ring-opening and po...

Embodiment 3

[0046] The preparation process of membrane-grade nylon 6 slices is the same as in Example 1, the difference is that step 1) adds 30% by weight of solid caprolactam to the extraction concentrate, the temperature heated by the steam heat exchanger is 100°C, and the differential pressure alarm device controls the pressure at 45-55kpa, the water content of the mixture from the purification kettle is controlled at 15% by weight, and the purified mixture is obtained from the purification kettle. The mixture from the purification kettle: the fresh caprolactam mass ratio is 1:2 and sent to the caprolactam large storage tank. Obtain liquid A, additive comprises and accounts for the chain terminator benzoic acid of liquid A gross weight 0.03%, accounts for the conventional nucleating agent of liquid A gross weight 0.01%, accounts for the antiblocking agent talcum powder of liquid A gross weight 0.01%; step 2) The middle preheater is heated to 120°C, and the obtained material is sent into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com