Water-proof anti-corrosive thermal-insulating coating and preparation method thereof

A heat-insulating coating and heat-insulating filler technology, applied in anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of low film-forming substance content, low solid content of coatings, poor anti-corrosion performance, etc., to achieve increased solid content, dry Faster speed and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

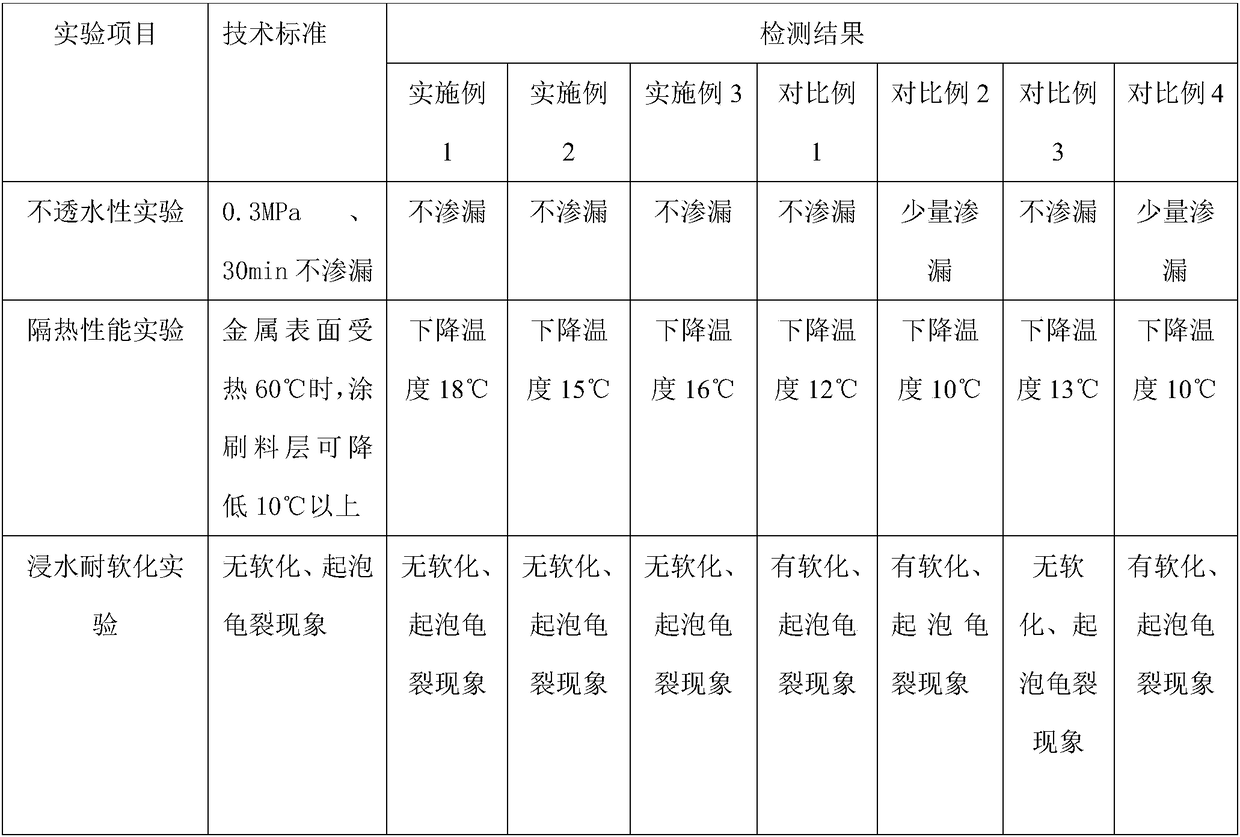

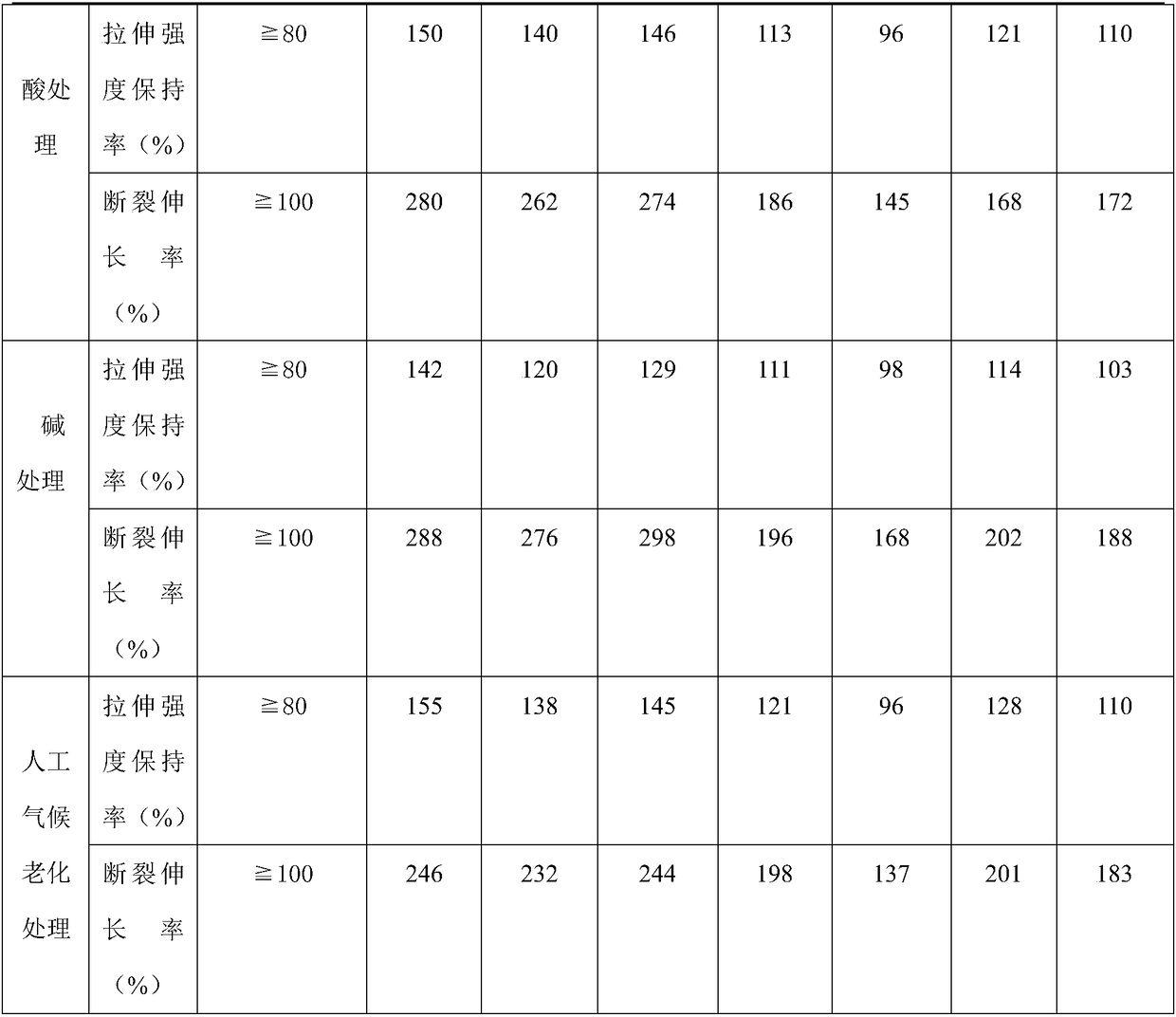

Examples

Embodiment 1

[0043] 1) Weigh 12% of high hydrogen-containing silicone oil emulsion and 5% of deionized water according to mass percentage, mix evenly under 200r / min low-speed stirring, then add 0.8% of ethylene glycol, 0.3% of dispersing Agent, 0.1% defoamer, 0.1% preservative, 0.1% leveling agent, 0.1% color paste, disperse evenly under high-speed stirring at 1200r / min to obtain a mixture;

[0044] 2) Add 10% of titanium dioxide, 5% of 100-mesh mica powder, 0.3% of 8nm nano heat insulation powder, and 0.5% of magnesium aluminum silicate to the mixture in sequence under stirring at a medium speed of 500r / min. , 0.1% hydroxyethyl cellulose, after 1200r / min high-speed stirring to disperse evenly, add it to the sand mill for sand grinding;

[0045] 3) Put the sand-milled mixture into a disperser, add 3% of 150-mesh vitrified microbeads under a medium-speed stirring of 500r / min, and after the dispersion is uniform, stir at a low speed of 200r / min, and then add 30% of benzene Acrylic emulsion,...

Embodiment 2

[0047] 1) Weigh 5% of high hydrogen-containing silicone oil emulsion and 2% of deionized water according to mass percentage, mix evenly under 150r / min low-speed stirring, then add 1.2% of ethylene glycol, 0.7% of dispersing Agent, 0.2% defoamer, 0.3% preservative, 0.3% leveling agent, 0.3% color paste, uniformly dispersed under 800r / min high-speed stirring, to obtain a mixture;

[0048] 2) Add 12.2% of titanium dioxide, 20% of 300-mesh mica powder, 0.1% of 12nm nano heat insulation powder, and 0.2% of magnesium aluminum silicate to the mixture in sequence under stirring at a medium speed of 500r / min. , 0.3% hydroxyethyl cellulose, after dispersing evenly under 800r / min high-speed stirring, add it to the sand mill for sand grinding;

[0049] 3) Put the sand-milled mixture into a disperser, add 2% of 250-mesh vitrified microbeads under a medium-speed stirring of 500r / min, and after the dispersion is uniform, stir at a low speed of 150r / min, and then add 40% of benzene Acrylic e...

Embodiment 3

[0051] 1) Weigh 8% of high hydrogen-containing silicone oil emulsion and 3% of deionized water according to the mass percentage, mix evenly under low-speed stirring of 200r / min, then add 1% of ethylene glycol, 0.3% of dispersing Agent, 0.2% defoamer, 0.2% preservative, 0.2% leveling agent, 0.2% color paste, uniformly dispersed under 1000r / min high-speed stirring, to obtain a mixture;

[0052] 2) Add 15% of titanium dioxide, 15% of 100-mesh mica powder, 0.2% of 10nm nano heat insulation powder, and 0.3% of magnesium aluminum silicate to the mixture in sequence under stirring at a medium speed of 500r / min. , 0.2% hydroxyethyl cellulose, after 1000r / min high-speed stirring and dispersing evenly, add it into the sand mill for sand grinding;

[0053] 3) Put the sand-milled mixture into a disperser, add 2% of 150-mesh vitrified microbeads under a medium-speed stirring of 500r / min, and after the dispersion is uniform, stir at a low speed of 200r / min, and then add 33% of benzene Acry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com