Acid paddy soil modifier

A soil improver and rice technology, applied in the field of agricultural science, can solve problems such as the inhibition of soil microbial activity, the activation of toxic heavy metals, and the loss of nutrients, so as to reduce soil acid damage, increase yield and quality of agricultural products, and reduce heavy metals. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

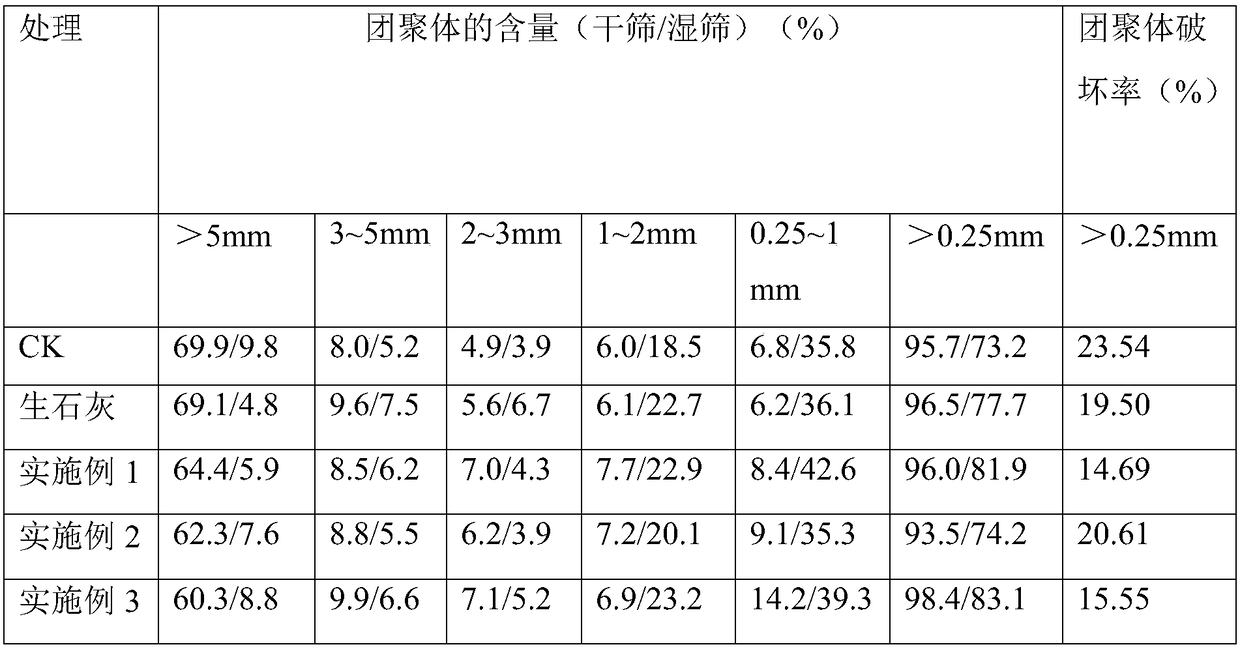

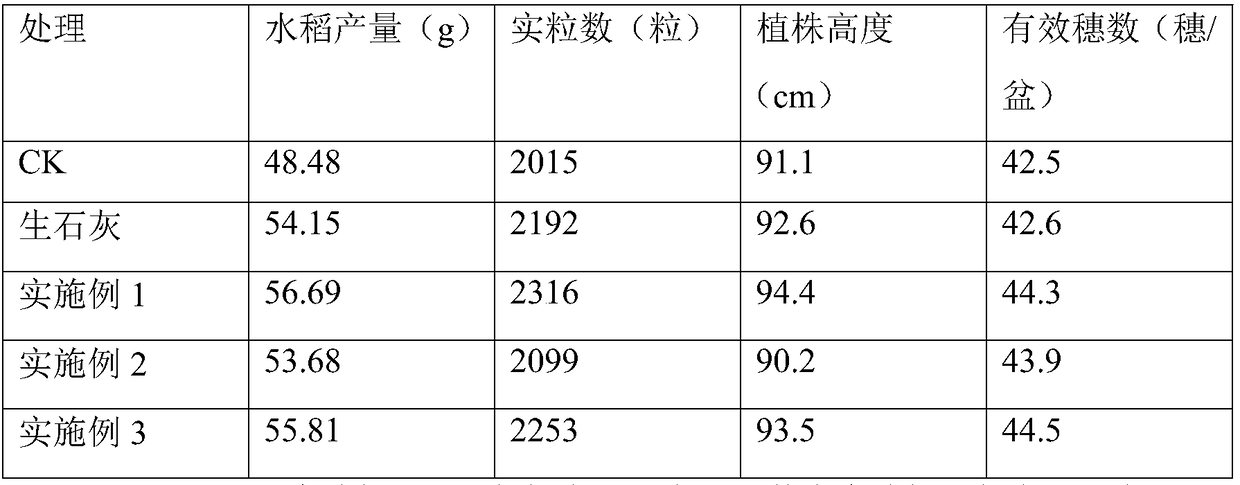

Examples

Embodiment 1

[0025] Embodiment 1: prepare soil conditioner as follows

[0026] The components of the soil conditioner are:

[0027] 3 parts of biomass black carbon, 5 parts of dolomite, 10 parts of sepiolite, 15 parts of limestone, 6 parts of 200 mesh powdery zeolite, 10 parts of 4-10mm vermiculite, 5 parts of bentonite, pulverized coal with 2%wt bitumen 40 parts of ash, 20 parts of polyacrylamide with an average molecular weight of 17.5 million, 30 parts of arbuscular mycorrhizal fungal agent, 22 parts of decomposed pig manure, and 3 parts of superabsorbent resin.

[0028] Preparation method:

[0029] (1) Preparation of arbuscular mycorrhizal fungal agent:

[0030] (A) Substrate preparation: mix by grass carbon: vermiculite: perlite: zeolite (volume ratio) is the ratio of 2:2:2:1, high pressure steam sterilization standby;

[0031] (B) the inoculants that contain three kinds of mycorrhizal fungal spores and mycelia of Glomus moses, Glomus in root, Glomus proteus respectively are mixed ...

Embodiment 2

[0040] Embodiment 2: prepare soil conditioner as follows

[0041] 1 part of biomass black carbon, 1 part of dolomite, 5 parts of sepiolite, 10 parts of limestone, 2 parts of 150 mesh powdery zeolite, 5 parts of 4mm vermiculite, 2 parts of bentonite, 30 parts of fly ash containing 1%wt bitumen 10 parts of polyacrylamide with an average molecular weight of 15 million, 10 parts of arbuscular mycorrhizal fungal agent, 15 parts of decomposed pig manure, and 1 part of superabsorbent resin.

[0042] Preparation method:

[0043] (1) Preparation of arbuscular mycorrhizal fungal agent:

[0044] (A) Substrate preparation: mix by grass carbon: vermiculite: perlite: zeolite (volume ratio) is the ratio of 2:2:2:1, high pressure steam sterilization standby;

[0045] (B) the inoculants that contain three kinds of mycorrhizal fungal spores and mycelia of Glomus moses, Glomus in root, Glomus proteus respectively are mixed first, the spore density of each strain is 30 / gram, then Spread the mi...

Embodiment 3

[0054] Embodiment 3: prepare soil conditioner as follows

[0055] 5 parts of biomass black carbon, 10 parts of dolomite, 15 parts of sepiolite, 20 parts of limestone, 10 parts of 250 mesh powdery zeolite, 15 parts of 10mm vermiculite, 8 parts of bentonite, 50 parts of fly ash containing 3%wt pitch 30 parts of polyacrylamide with an average molecular weight of 20 million, 50 parts of arbuscular mycorrhizal fungal agent, 30 parts of decomposed pig manure, and 5 parts of superabsorbent resin.

[0056] Preparation method:

[0057] (1) Preparation of arbuscular mycorrhizal fungal agent:

[0058] (A) Substrate preparation: mix by grass carbon: vermiculite: perlite: zeolite (volume ratio) is the ratio of 2:2:2:1, high pressure steam sterilization standby;

[0059] (B) the inoculant that contains three kinds of mycorrhizal fungal spores and mycelia of Glomus moses, Glomus in root, Glomus proteus respectively is mixed first, the spore density of each strain is 100 / gram, then Spread ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com