Melt spinning preparation method of high molecular weight polyethylene fiber

A polyethylene fiber, high molecular weight technology, used in melt spinning, single-component polyolefin rayon, stretch spinning, etc., can solve the problems of low melt flow rate, difficult preparation, and high melt viscosity , to achieve the effect of improving melt flow properties, increasing production rate and high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

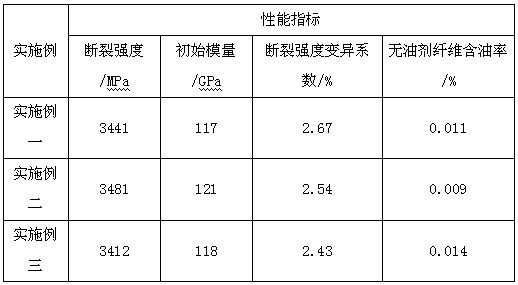

Embodiment 1

[0034] (1) Add 5 parts by mass of kaolin raw ore and 100 parts by mass of deionized water into the mixing tank. After fully stirring, let it stand for 10 minutes, siphon out the suspension in the upper 40mm part, and then add and suck out the suspension in the mixing tank deionized water equal to the volume of the liquid, then stirred, settled and extracted, and repeated several times until the suspension within the upper 40 mm of the mixing barrel was no longer turbid after adding deionized water and stirring for 10 minutes, and filtered the obtained kaolin slurry , drying to obtain purified kaolin;

[0035] (2) Add 3 parts by mass of the purified kaolin prepared in step (1) and 20 parts by mass of deionized water into an electric mixer, and stir and disperse with an electric mixer for 2 hours at room temperature, and mix 5 parts by mass of Add sodium hydroxide solution with a fraction of 4% into the electric stirrer, continue to stir for 2 hours at room temperature, then cen...

Embodiment 2

[0045] (1) Add 8 parts by mass of kaolin raw ore and 150 parts by mass of deionized water into the mixing tank. After fully stirring, let it stand for 20 minutes, siphon out the suspension in the upper 75mm part, and then add and suck out the suspension in the mixing tank deionized water equal to the volume of the liquid, then stirred, settled and extracted, and repeated several times until the suspension within the upper 75 mm of the mixing barrel was no longer turbid after adding deionized water and stirring for 20 minutes, and filtered the obtained kaolin slurry , drying to obtain purified kaolin;

[0046] (2) Add 5 parts by mass of the purified kaolin prepared in step (1) and 30 parts by mass of deionized water into an electric stirrer, stir and disperse for 4 hours with an electric stirrer at room temperature, and mix 8 parts by mass of Add sodium hydroxide solution with a fraction of 4% into the electric stirrer, continue to stir for 3 hours at room temperature, then cen...

Embodiment 3

[0056] (1) Put 10 parts by mass of kaolin raw ore and 200 parts by mass of deionized water into the mixing tank. After fully stirring, let it stand for 30 minutes, siphon out the suspension in the upper 100mm part, and then add and suck out the suspension in the mixing tank Deionized water equal to the volume of the liquid, then stirred, settled and extracted, and repeated several times until the suspension within the upper 100 mm of the mixing barrel was no longer turbid after adding deionized water and stirring for 30 minutes, then filtered the obtained kaolin slurry , drying to obtain purified kaolin;

[0057] (2) Add 7.5 parts by mass of the purified kaolin prepared in step (1) and 50 parts by mass of deionized water into an electric mixer, and stir and disperse for 5 hours with an electric stirrer at room temperature, and mix 10 parts by mass of Add sodium hydroxide solution with a fraction of 4% into the electric stirrer, continue to stir for 4 hours at room temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com