Electrolyte separator for vanadium battery and preparation method of electrolyte separator

A technology of electrolyte diaphragm and vanadium battery, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of anion exchange membrane human body and environmental hazards, thermal stability and chemical stability need to be further improved, and achieve equipment and reaction The conditions are not high, the ion exchange capacity is improved, and the preparation method is simple and easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

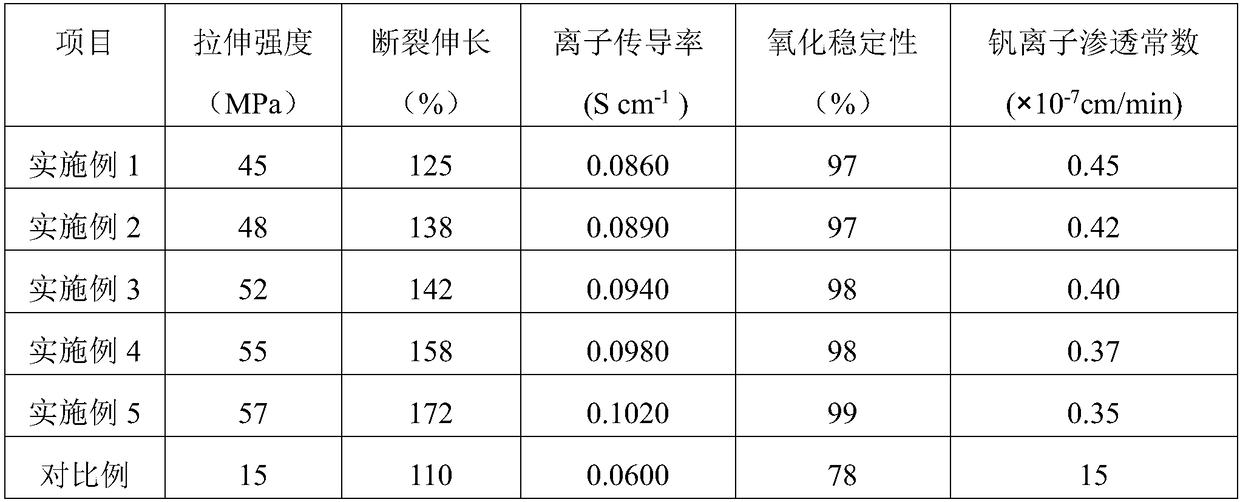

Examples

Embodiment 1

[0027] A preparation method for an electrolyte diaphragm for a vanadium battery, comprising the steps of:

[0028] 1) Preparation of quaternary ammonium salt-type silane: Add 12 g of epichlorohydrin into a three-necked flask, slowly add 10 g of bis(diethylamino)silane dropwise with a constant pressure dropping funnel, and reflux at 50° C. for about 6 hours. Rotary evaporation to remove excess epichlorohydrin, recrystallization in acetone 3 times, and then rotary evaporation to remove acetone again to obtain quaternary ammonium silane;

[0029] 2) Preparation of polymer: Dissolve 14.4 g of quaternary ammonium silane and 10 g of 4,4-dihydroxydiphenyl sulfone prepared in step 1) in 60 g of dimethyl sulfoxide, and then add benzyl 5 g of dimethylamine, stirred and reacted at 90° C. for 6 hours in a nitrogen atmosphere, then precipitated in acetone, washed the product with ethanol for 3 times, and dried in a vacuum oven at 60° C. for 10 hours;

[0030] 3) Preparation of diaphragm: ...

Embodiment 2

[0034] A preparation method for an electrolyte diaphragm for a vanadium battery, comprising the steps of:

[0035] 1) Preparation of quaternary ammonium salt-type silane: Add 13g of epichlorohydrin into a three-necked flask, slowly add 10g of bis(diethylamino)silane dropwise with a constant pressure dropping funnel, and reflux at 52°C for about 6.5h . Remove excess epichlorohydrin by rotary evaporation, recrystallize in acetone 4 times, and then remove acetone by rotary evaporation again to obtain quaternary ammonium silane;

[0036] 2) Preparation of polymer: Dissolve 14.4 g of quaternary ammonium silane and 10 g of 4,4-dihydroxydiphenyl sulfone prepared in step 1) in 75 g of N,N-dimethylformamide, and wait until completely After dissolving, add 6.5g of tetrabutylammonium bromide, stir and react for 6.5 hours in a helium atmosphere at a temperature of 93°C, then precipitate in acetone, wash the product with ethanol for 4 times, and place it in a vacuum drying oven at 65°C B...

Embodiment 3

[0041] A preparation method for an electrolyte diaphragm for a vanadium battery, comprising the steps of:

[0042] 1) Preparation of quaternary ammonium salt type silane: Add 13.5g of epichlorohydrin into a three-necked flask, slowly add 10g of bis(diethylamino)silane dropwise with a constant pressure dropping funnel, and reflux at 56°C for about 7h . Rotary evaporation to remove excess epichlorohydrin, recrystallization in acetone 5 times, and then rotary evaporation to remove acetone again to obtain quaternary ammonium salt type silane;

[0043]2) Preparation of polymer: Dissolve 14.4 g of quaternary ammonium silane and 10 g of 4,4-dihydroxydiphenyl sulfone prepared in step 1) in 95 g of N-methylpyrrolidone. After completely dissolving, add Benzyltriethylammonium chloride 7.5g, stirred and reacted at 96°C for 7 hours in a neon atmosphere, then precipitated in acetone, washed the product with ethanol for 5 times, and dried in a vacuum oven at 71°C for 13 Hour;

[0044] 3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com