High-temperature type polymer lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and polymers, applied in the direction of secondary batteries, battery electrodes, battery pack components, etc., can solve the problems of difficult to guarantee battery performance, difficult to discharge normally, short cycle life, etc., and achieve surface density and pressure Moderate solid density, lower battery impedance, and good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

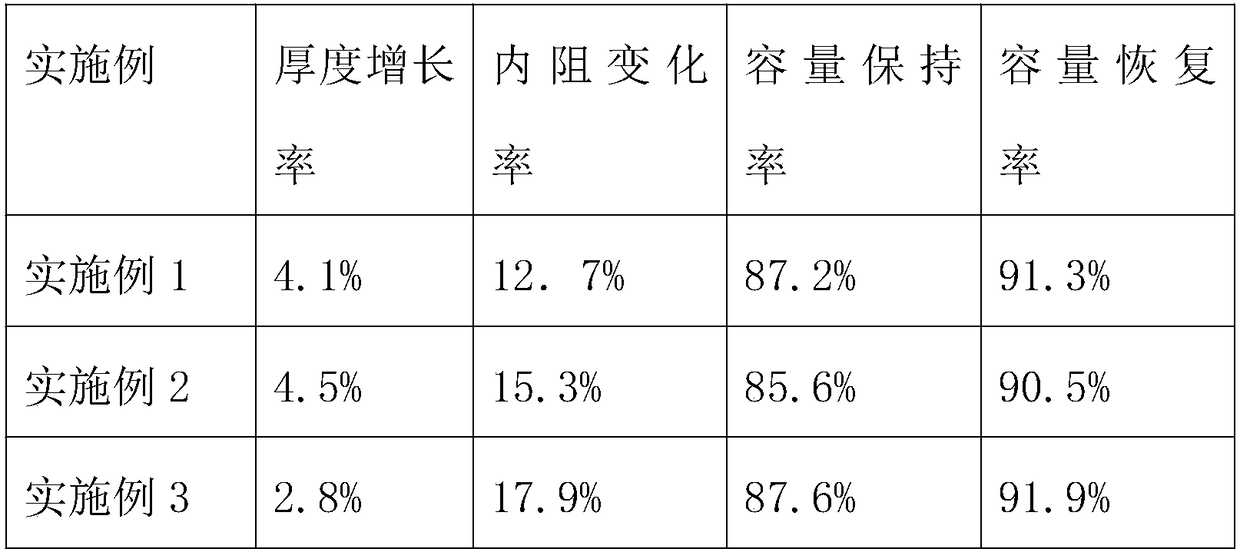

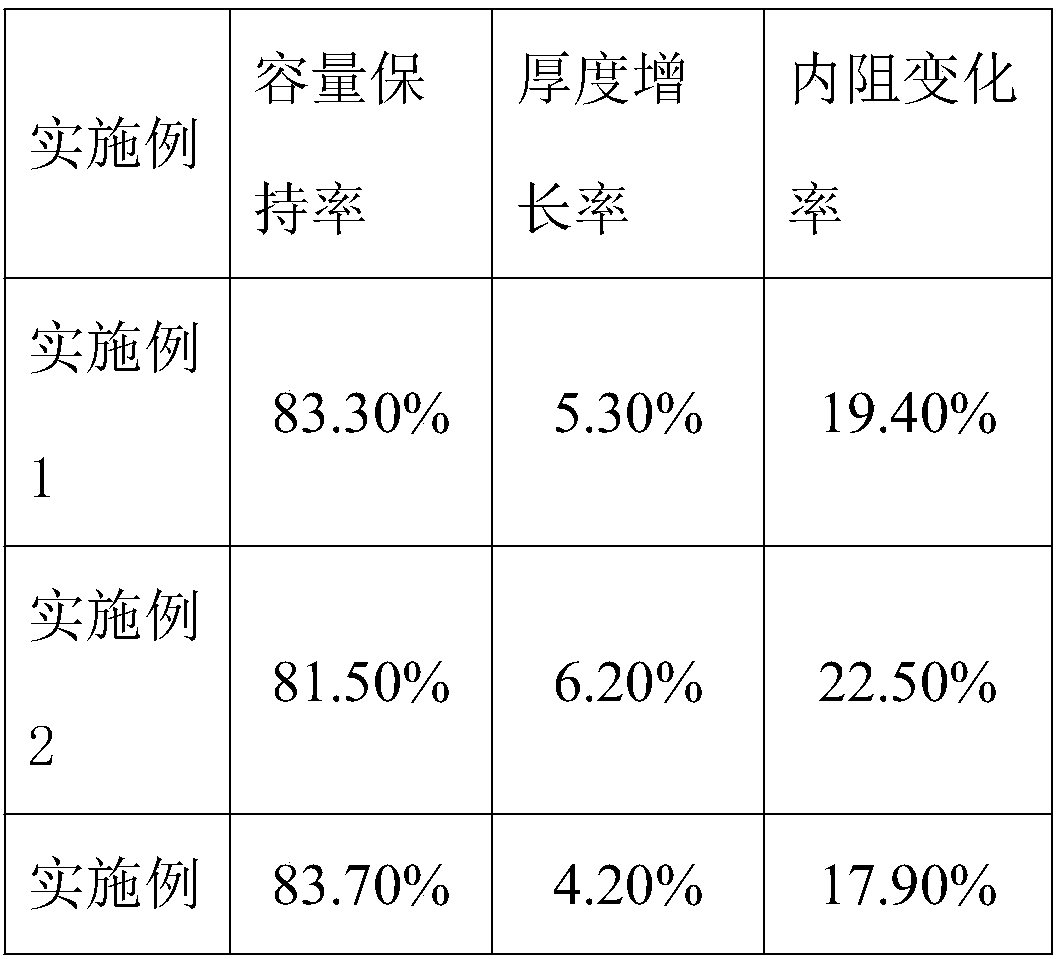

Embodiment 1

[0035] The lithium cobalt oxide D10 of the positive electrode sheet is 11 μm, and the specific surface area is: 0.2m 2 / g

[0036] The artificial graphite D10 of the negative electrode sheet is 13 μm, and the specific surface area is: 0.9m 2 / g.

[0037] The base film of the separator is a polyethylene porous film, the thickness of the base film is 12 μm, the mixed coating is a mixture of aluminum oxide and polyvinylidene fluoride, the mass ratio of the two is 1:1, and the thickness of the coating is 3 μm , the coating corresponds to the positive side.

[0038] The lithium salt of the electrolyte is LiPF6, and the content of the lithium salt is 1.0mol / L;

[0039] The mass ratio of each component of the carbonate mixture is ethylene carbonate (EC): propylene carbonate (PC): diethyl carbonate (DEC): ethylmethyl carbonate (EMC)=40:15:30:15 ;

[0040] The additive content accounts for 5.5% of the total mass of the electrolyte, and the mass ratio of various additives is: fluor...

Embodiment 2

[0052] The lithium cobalt oxide D10 of the positive electrode sheet is 11 μm, and the specific surface area is: 0.2m 2 / g;

[0053] The artificial graphite D10 of the negative electrode sheet is 13 μm, and the specific surface area is: 0.9m2 / g.

[0054] The base film of the separator is a polyethylene porous film, the thickness of the base film is 12 μm, the mixed coating is composed of a mixture of aluminum oxide and polyvinylidene fluoride, the thickness of the coating is 3 μm, and the coating corresponds to the positive electrode surface.

[0055] The lithium salt of the electrolyte is LiPF6, and the content of the lithium salt is 1.0mol / L;

[0056] The mass ratio of each component of the carbonate mixture is ethylene carbonate (EC): propylene carbonate (PC): diethyl carbonate (DEC): ethylmethyl carbonate (EMC)=40:15:30:15 ; The carbonate mixture accounts for 81.5% of the total mass of the electrolyte.

[0057] The additive content accounts for 5.5% of the total mass of...

Embodiment 3

[0069] The lithium cobalt oxide D10 of the positive electrode sheet is 11 μm, and the specific surface area is: 0.2m 2 / g;

[0070] The artificial graphite D10 of the negative electrode sheet is 13 μm, and the specific surface area is: 0.9m 2 / g.

[0071] The base film of the separator is a polyethylene porous film, the thickness of the base film is 12 μm, the mixed coating is composed of a mixture of aluminum oxide and polyvinylidene fluoride, the thickness of the coating is 3 μm, and the coating corresponds to the positive electrode surface.

[0072] The lithium salt of the electrolyte is LiPF6, and the content of the lithium salt is 1.0mol / L;

[0073] The mass ratio of each component of the carbonate mixture is ethylene carbonate (EC): propylene carbonate (PC): diethyl carbonate (DEC): ethylmethyl carbonate (EMC)=40:15:30:15 ;

[0074] The additive content accounts for 6.5% of the total mass of the electrolyte, and the mass ratio of various additives is: fluoroethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com