High-molecular antibacterial liquid membrane and preparation method thereof

A liquid film and polymer technology, applied in the field of film materials, can solve the problems of weak adhesion, weak antibacterial activity, slow film forming speed, etc., achieve good biocompatibility and air permeability, promote wound healing, reduce The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

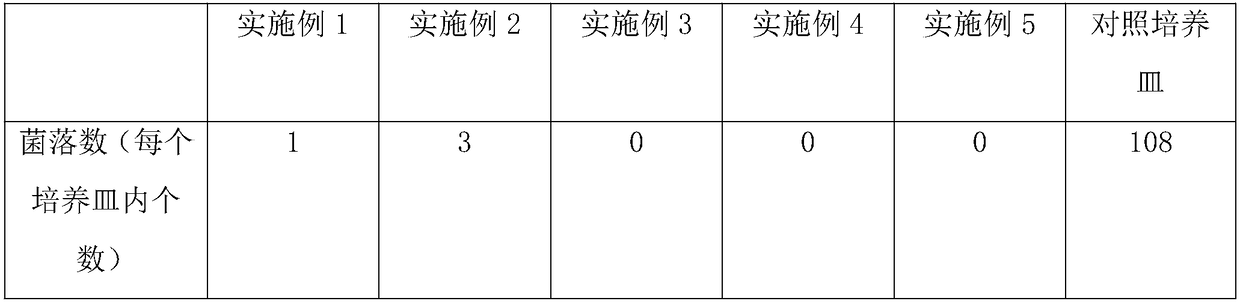

Examples

Embodiment 1

[0024] A polymer antibacterial liquid film, comprising the following components by weight: 100 parts of purified water, 100 parts of ethanol, 10 parts of polyvinyl alcohol, 10 parts of chitosan, 1 part of dimethyl phthalate, and 1 part of diethyl ether , 1 part of glycerol, 0.02 part of nano silver sol.

[0025] The ethanol is an aqueous ethanol solution with a mass fraction of 95%. .

[0026] The polyvinyl alcohol is formed by mixing polyvinyl alcohol 05 and polyvinyl alcohol 17, and the mass ratio is 0.2:1. The degree of polymerization of 17 is 1700-1800, the molecular weight is 78400-79200, and the alcoholysis degree of the polyvinyl alcohol 05 and the polyvinyl alcohol 17 is 86% to 90%.

[0027] The nano-silver sol is prepared by reducing soluble silver ions with natural materials. The natural materials include monosaccharides, double ponds, soluble starches or mixtures thereof. The natural materials specifically selected within this range have no effect on the technical...

Embodiment 2

[0033] A polymer antibacterial liquid film, comprising the following components by weight: 100 parts of purified water, 100 parts of ethanol, 30 parts of polyvinyl alcohol, 30 parts of chitosan, 5 parts of dimethyl phthalate, and 10 parts of ether , 10 parts of glycerol, 0.03 part of nano silver sol.

[0034] The ethanol is an aqueous ethanol solution with a mass fraction of 95%. .

[0035] The polyvinyl alcohol is formed by mixing polyvinyl alcohol 05 and polyvinyl alcohol 17, and the mass ratio is 0.3:1. The degree of polymerization of 17 is 1700-1800, the molecular weight is 78400-79200, and the alcoholysis degree of the polyvinyl alcohol 05 and the polyvinyl alcohol 17 is 86% to 90%.

[0036] The nano-silver sol is prepared by reducing soluble silver ions with natural materials. The natural materials include monosaccharides, double ponds, soluble starches or mixtures thereof. The natural materials specifically selected within this range have no effect on the technical ef...

Embodiment 3

[0042] A polymer antibacterial liquid film, comprising the following components by weight: 100 parts of purified water, 100 parts of ethanol, 15 parts of polyvinyl alcohol, 15 parts of chitosan, 2 parts of dimethyl phthalate, and 3 parts of diethyl ether , 3 parts of glycerol, 0.07 part of nano silver sol.

[0043] The ethanol is an aqueous ethanol solution with a mass fraction of 95%. .

[0044] The polyvinyl alcohol is formed by mixing polyvinyl alcohol 05 and polyvinyl alcohol 17, the mass ratio is 0.4:1, the polyvinyl alcohol 05 has a degree of polymerization of 500-600, and a molecular weight of 22000-22600. The degree of polymerization of 17 is 1700-1800, the molecular weight is 78400-79200, and the alcoholysis degree of the polyvinyl alcohol 05 and the polyvinyl alcohol 17 is 86% to 90%.

[0045] The nano-silver sol is prepared by reducing soluble silver ions with natural materials. The natural materials include monosaccharides, double ponds, soluble starches or mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com