Method for preparing HMF (5-hydroxymethylfurfural) from glucose by lower-temperature catalysis with boehmite

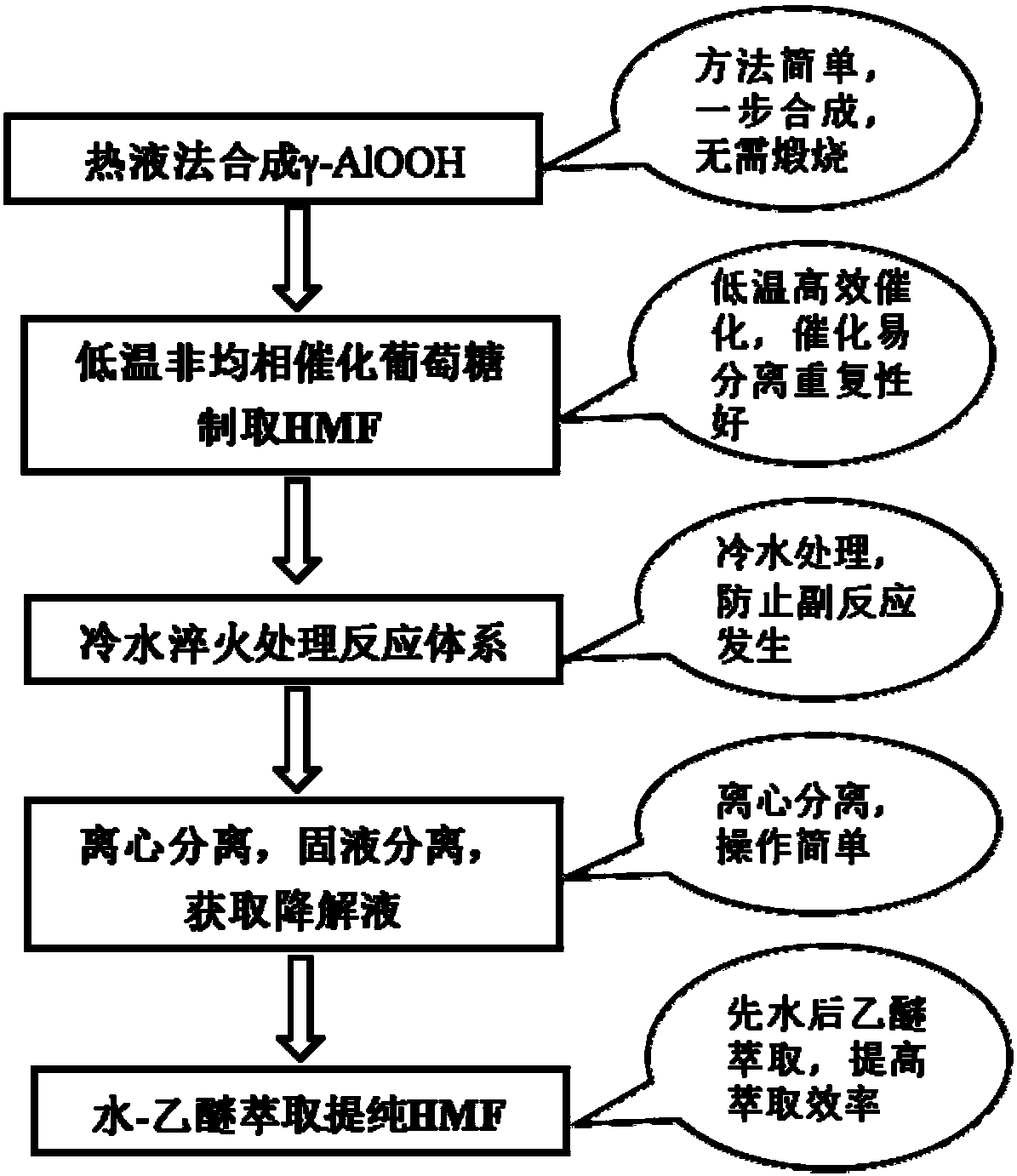

A technology of hydroxymethyl furfural and boehmite, applied in chemical recovery, organic chemistry and other directions, can solve problems such as high reaction temperature and complicated catalyst preparation, achieve simple preparation method, good industrial application prospect, and avoid a large number of side reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

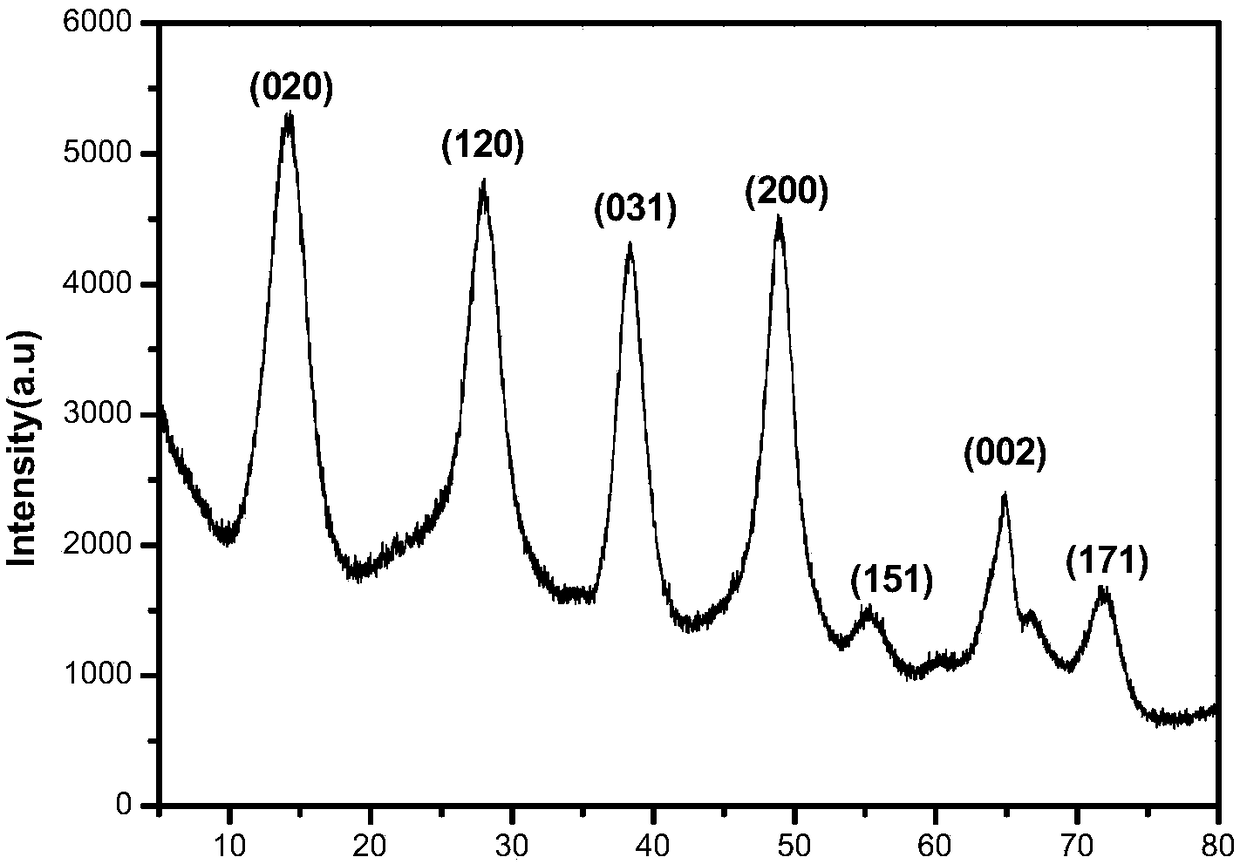

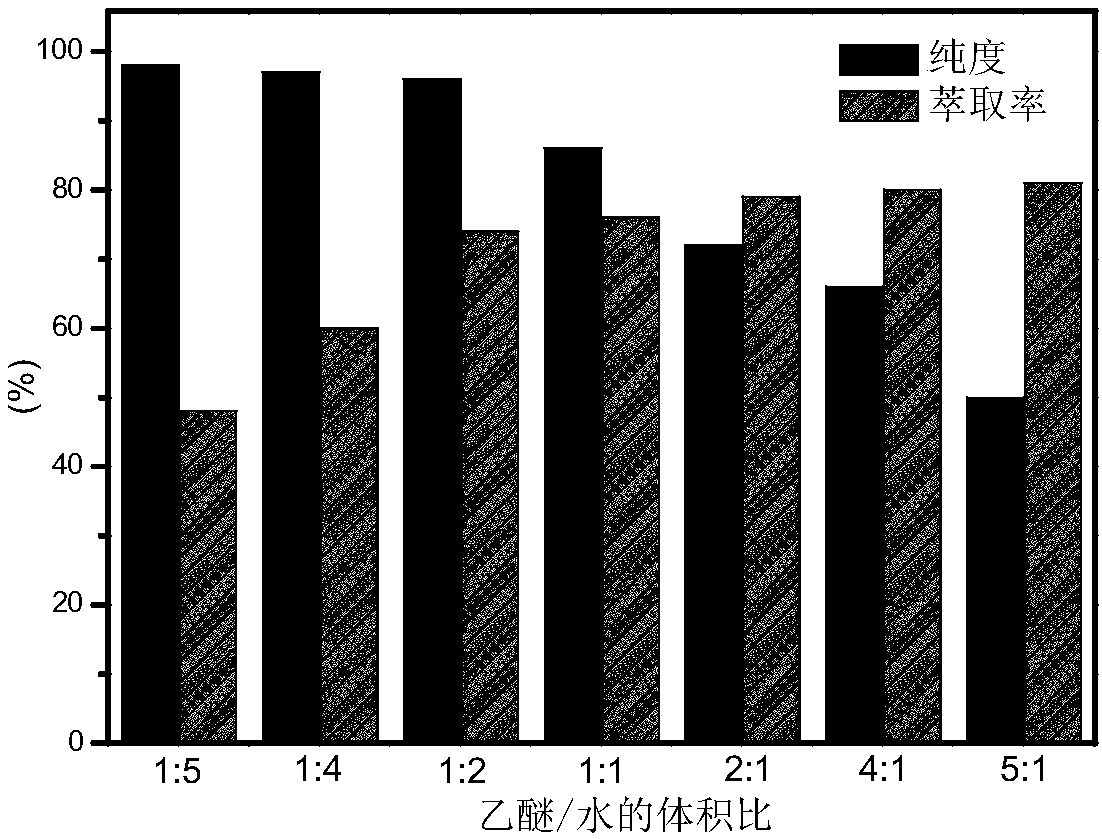

[0032] 30mmol NH 4 HCO 3 and 15mmol Al(NO 3 ) 3was added to 50 mL of deionized water with vigorous stirring. After it became a clear and transparent homogeneous solution, 25% concentrated ammonia solution was slowly added dropwise to adjust the pH to 9. After it became a homogeneous mixed solution, it was transferred to a 100 mL Teflon-lined reaction kettle, and reacted at 150° C. for 12 h. When the reaction time reaches the set time, take out the reactor. After being naturally cooled to room temperature, the reactor was opened to separate and wash the catalyst to obtain a solid product. Finally, the solid product was dried at 150° C. for 12 h to obtain the solid catalyst γ-AlOOH. This solid catalyst was subjected to XRD analysis. like figure 2 shown, from figure 2 It can be seen that all the diffraction peaks of the sample are consistent with the diffraction peaks of the orthogonal γ-AlOOH (JCPDS 021-1307) marker, and no diffraction peaks of other substances are ob...

Embodiment 2

[0036] The preparation method of γ-AlOOH is the same as that of Example 1. The experimental process of glucose conversion to prepare HMF is also the same as in Example 1.

[0037] The amount of dimethyl sulfoxide (DMSO) was increased to 2.0 g during the preparation of 5-hydroxymethylfurfural. The specific process is as follows: 0.1 g of glucose and 0.1 g of solid catalyst γ-AlOOH were added to 2.0 g of dimethyl sulfoxide, and after stirring evenly, the above solution was transferred to an oil bath at 130 °C, and the reaction was conducted under magnetic stirring for 3 h. After the reaction was completed, 20 mL of cold deionized water was immediately added to the reaction solution for quenching treatment. The centrifuge was then used for separation at a speed of 10,000 rpm for 5 min, and the upper layer liquid was collected to obtain a degradation solution containing HMF. Take out a small amount of this degradation solution, dilute it 300 times with deionized water, and then ...

Embodiment 3

[0039] The preparation method of γ-AlOOH is the same as that of Example 1. The experimental process of glucose conversion to prepare HMF is also the same as in Example 1.

[0040] The amount of dimethyl sulfoxide (DMSO) was reduced to 0.5 g during the preparation of 5-hydroxymethylfurfural. The specific process is as follows: 0.1 g of glucose and 0.1 g of solid catalyst γ-AlOOH were added to 0.5 g of dimethyl sulfoxide, and after stirring evenly, the above solution was transferred to a 130 °C oil bath pot, and the reaction was conducted under magnetic stirring for 3 h. After the reaction was completed, 20 mL of cold deionized water was immediately added to the reaction solution for quenching treatment. The centrifuge was then used for separation at a speed of 10,000 rpm for 5 min, and the upper layer liquid was collected to obtain a degradation solution containing 5-hydroxymethylfurfural. Take out a little of this degradation solution, dilute it 200 times with deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com