Three-stage heating device, biochar preparation system and preparation method

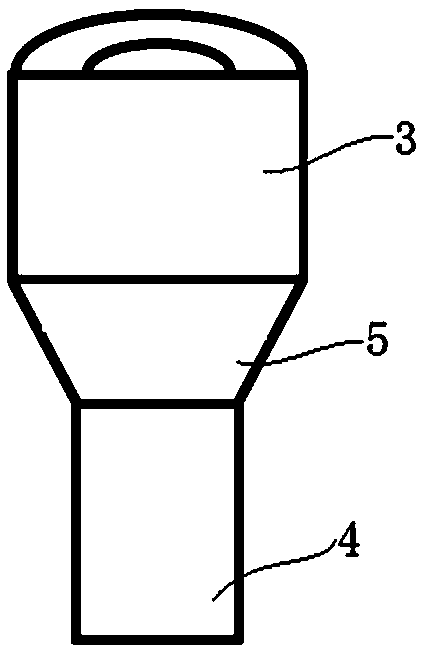

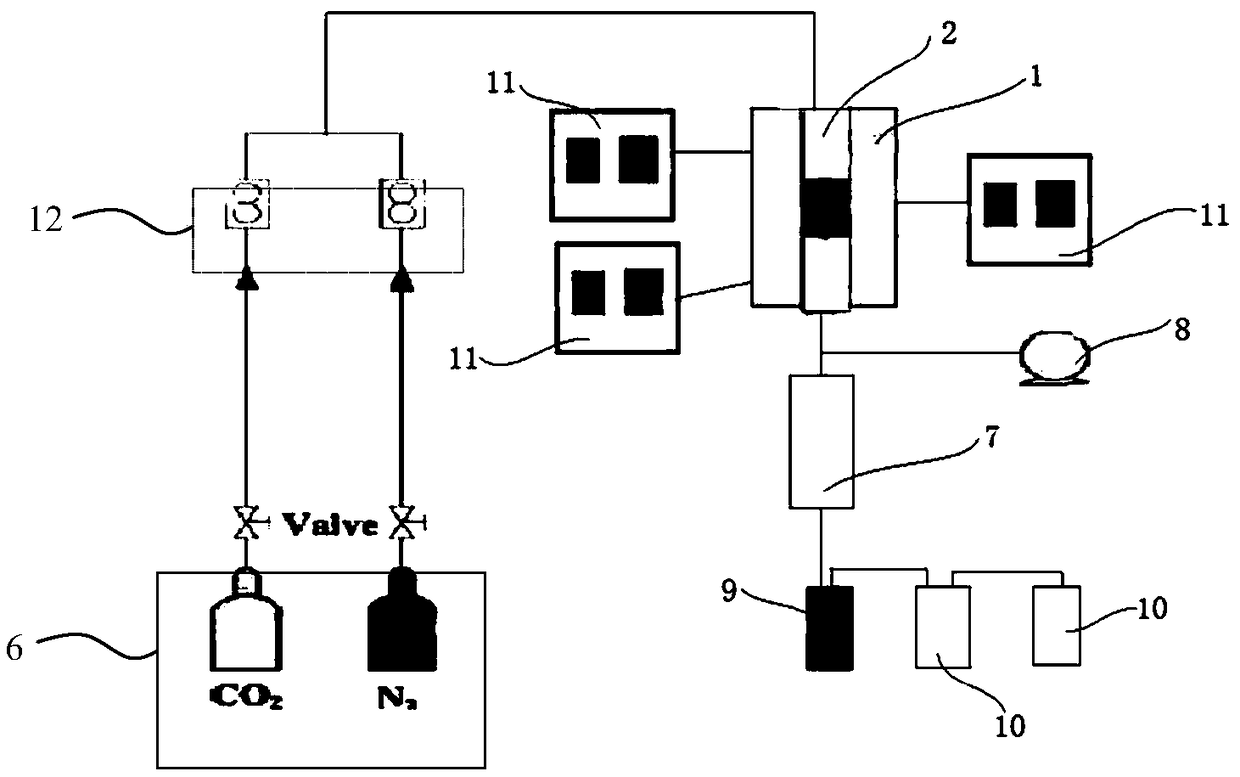

A heating device and a three-stage technology, which are applied to the three-stage heating device and the biochar preparation system and preparation field, can solve the problems of not effectively solving the program heating and temperature control, unable to obtain industrial application, unfavorable to research and production, and the like, Achieve the effect of rapid gas-liquid-solid three-phase separation, weakening temperature layer excursion, and excellent adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for preparing biochar by adopting coconut shell comprises the steps:

[0030] (1) Pretreatment of coconut shells: after washing and drying the coconut shells, dry them in an oven at 80°C to constant weight, and then use an LFP-800 pulverizer to pulverize them to a particle size of 5mm to 10mm;

[0031] (2) Add the crushed coconut shell from the feed end of the variable diameter reactor 2 in the three-stage heating device, start three temperature control devices 11 respectively, set the pyrolysis temperature at 600 ° C, and the heating rate at 20 ° C / min, while adjusting the gas flow control device 12 to set the gas velocity of the pyrolysis gas to 0.5L / min, and the pyrolysis reaction is 1h;

[0032] (3) After the pyrolysis reaction, adjust the cooling rate at 20°C / min to 300°C, set the gas velocity of the pyrolysis gas at 0.2L / min, and after cooling down to room temperature, the generated biochar is directly discharged from the variable-diameter reactor 2 ...

Embodiment 2

[0034] The method for preparing biochar by using rice stalks comprises the following steps:

[0035] (1) Pretreatment of rice straw: After washing and drying the rice straw, dry it in an oven at 70°C to constant weight, and then use an LFP-800 pulverizer to pulverize it to a particle size of 5 mm to 10 mm;

[0036] (2) Add crushed rice stalks from the feeding end of the variable-diameter reactor 2 in the three-stage heating device, start three temperature control devices 11 respectively, set the pyrolysis temperature to 600°C, and heat up at a rate of 15°C / min, while adjusting the gas flow control device 12 to set the gas velocity of the pyrolysis gas to 0.5L / min, and the pyrolysis reaction is 1h;

[0037] (3) After the pyrolysis reaction, adjust the cooling rate at 20°C / min to 300°C, set the gas velocity of the pyrolysis gas at 0.2L / min, and after cooling down to room temperature, the generated biochar is directly discharged from the variable-diameter reactor 2 The bio-oil ...

Embodiment 3

[0040] The method for preparing biochar by adopting apricot shells may further comprise the steps:

[0041] (1) Pretreatment of apricot shells: After washing and drying the apricot shells, dry them in an oven at 60°C to constant weight, and then use an LFP-800 pulverizer to crush them to a particle size of 5mm to 10mm;

[0042] (2) Add the pulverized apricot shells from the feed end of the variable diameter reactor 2 in the three-stage heating device, start three temperature control devices 11 respectively, set the pyrolysis temperature at 600 ° C, and the heating rate at 10 ° C / min, while adjusting the gas flow control device 12 to set the gas velocity of the pyrolysis gas to 0.5L / min, and the pyrolysis reaction is 1h;

[0043] (3) After the pyrolysis reaction, adjust the cooling rate at 20°C / min to 300°C, set the gas velocity of the pyrolysis gas at 0.2L / min, and after cooling down to room temperature, the generated biochar is directly discharged from the variable-diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com