Insulation Decorative Board Exterior Wall Exterior Insulation System

A technology for thermal insulation decorative panels and external wall thermal insulation, which is applied in the field of building wall materials, can solve the problems of extended construction period, labor and material cost, and damage to the wall insulation layer, and achieve excellent thermal insulation performance, increase curing speed, and improve resistance. cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

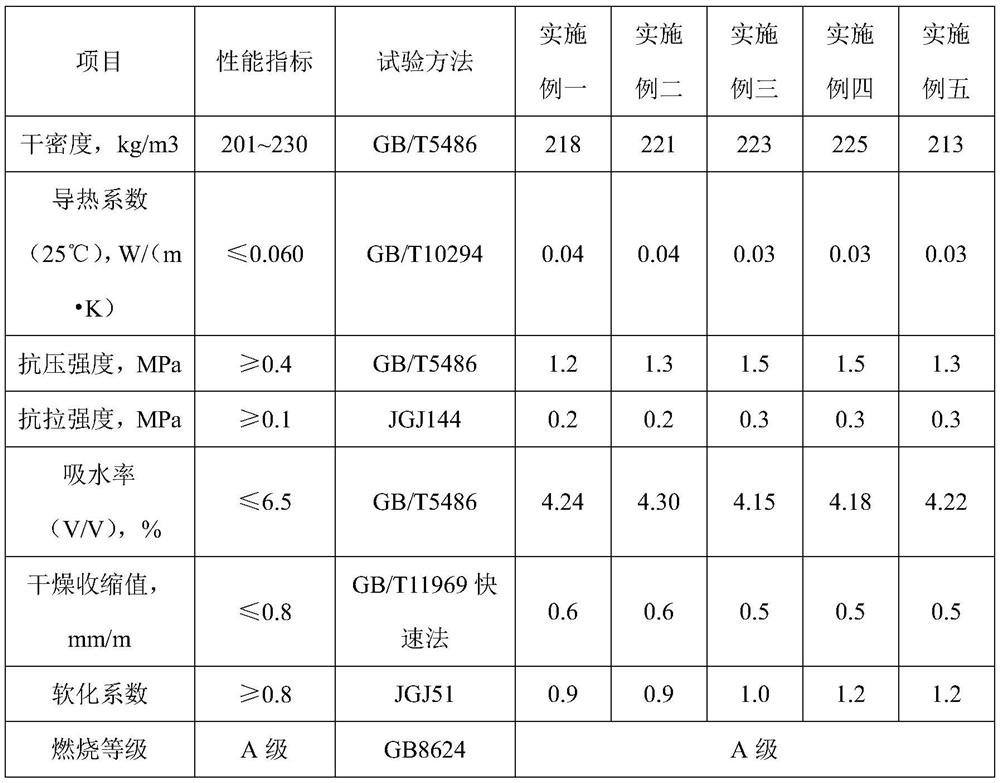

Embodiment 1

[0028] A preparation method of a gel glass bead insulation board, the specific steps are as follows:

[0029] (1) Preparation of active silica gel binder: Weigh 80 parts of diatomite slurry, 30 parts of cement clinker powder, 10 parts of calcium formate, 5 parts of polyborosiloxane and 1 part of KH-550 for high-speed mixing ,spare;

[0030] (2) Preparation of modified powder curing agent: a, 20 parts of powder curing agent, 50 parts of high-strength Portland cement, 1 part of active silica gel binder, 2 parts of nano-airgel, and 0.2 parts of polypropylene fiber Parts are uniformly mixed; b, the mixture in a is blended with 20 parts of anti-seepage water bonding material, and set aside;

[0031] (3) Molding: Weigh 100 parts of expanded perlite, 10 parts of inorganic silicon gel, 5 parts of cement-based binder, 20 parts of modified powder curing agent, 15 parts of nano-airgel and anti-seepage bonding material 5 parts were mixed to obtain a mixture; and the mixture was pressed ...

Embodiment 2

[0033]A preparation method of a gel glass bead insulation board, the specific steps are as follows:

[0034] (1) Preparation of active silica gel binder: Weigh 85 parts of diatomite slurry, 30 parts of cement clinker powder, 12 parts of calcium formate, 6 parts of polyborosiloxane and 1 part of KH-550 for high-speed mixing ,spare;

[0035] (2) Preparation of modified powder curing agent: a, 22 parts of powder curing agent, 52 parts of high-strength Portland cement, 1 part of active silica gel binder, 2 parts of nano-airgel, and 0.2 parts of polypropylene fiber Parts are uniformly mixed; b, the mixture in a is blended with 20 parts of anti-seepage water bonding material, and set aside;

[0036] (3) Molding: Weigh 105 parts of expanded perlite, 13 parts of inorganic silicon gel, 5 parts of cement-based binder, 20 parts of modified powder curing agent, 18 parts of nano-airgel and anti-seepage bonding material 5 parts were mixed to obtain a mixture; and the mixture was pressed i...

Embodiment 3

[0038] A preparation method of a gel glass bead insulation board, the specific steps are as follows:

[0039] (1) Preparation of active silica gel binder: Weigh 90 parts of diatomite slurry, 30 parts of cement clinker powder, 12 parts of calcium formate, 5 parts of polyborosiloxane and 2 parts of KH-550 for high-speed mixing ,spare;

[0040] (2) Preparation of modified powder curing agent: a, 24 parts of powder curing agent, 50 parts of high-strength Portland cement, 1.2 parts of active silica gel binder, 2 parts of nano-airgel, and 0.2 parts of polypropylene fiber Parts are uniformly mixed; b, the mixture in a is blended with 22 parts of anti-seepage water bonding material, for subsequent use;

[0041] (3) Molding: Weigh 110 parts of expanded perlite, 15 parts of inorganic silicon gel, 7 parts of cement-based binder, 22 parts of modified powder curing agent, 24 parts of nano-airgel and anti-seepage bonding material 8 parts were mixed to obtain a mixture; and the mixture was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com