Composite graphene aerogel electrode, preparation method and application thereof

A technology of graphene airgel and composite graphene, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve problems such as complex methods, aerogels without supercapacitors, etc., and achieve high mechanical stability , strong recovery elasticity, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method for a composite graphene airgel electrode, comprising the following steps:

[0035] 1) Cleaning of the electrode substrate: Cut the titanium sheet into a sample of 1cm×2cm, clean the sample with distilled water, ethanol, and acetone in sequence to remove surface impurities and oil, dry it in a vacuum drying oven, and then put it in nitrogen gloves spare in the box;

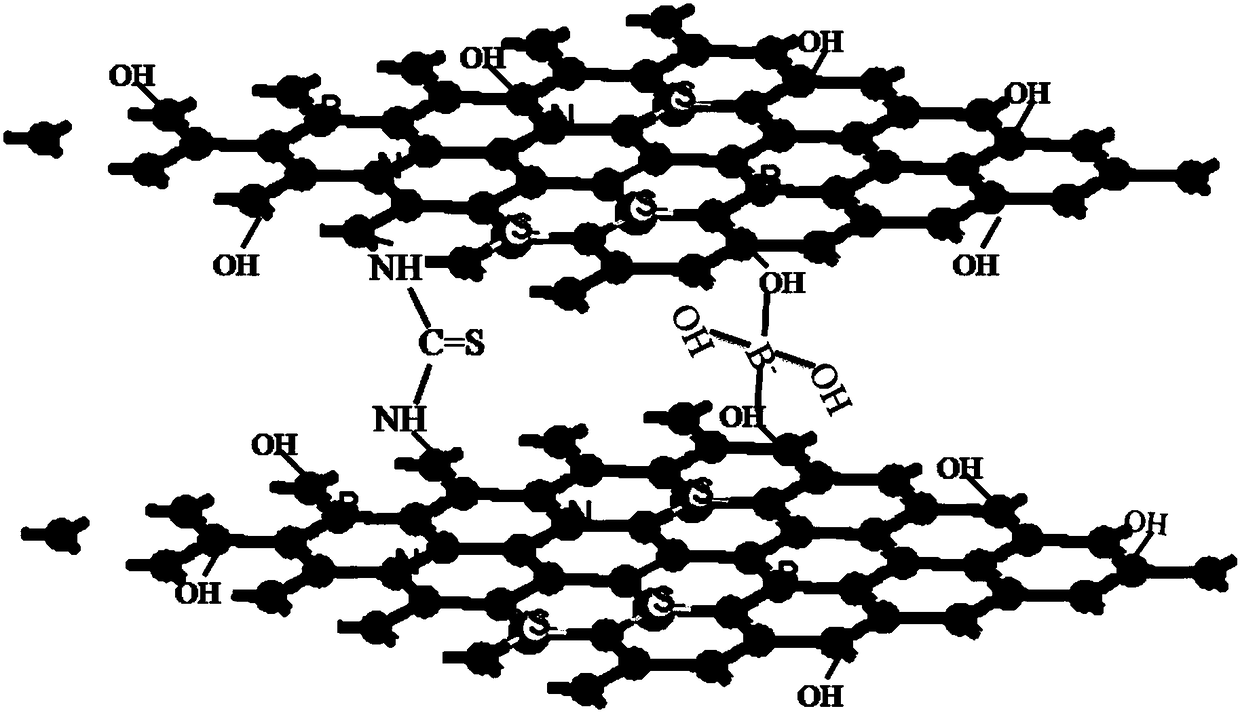

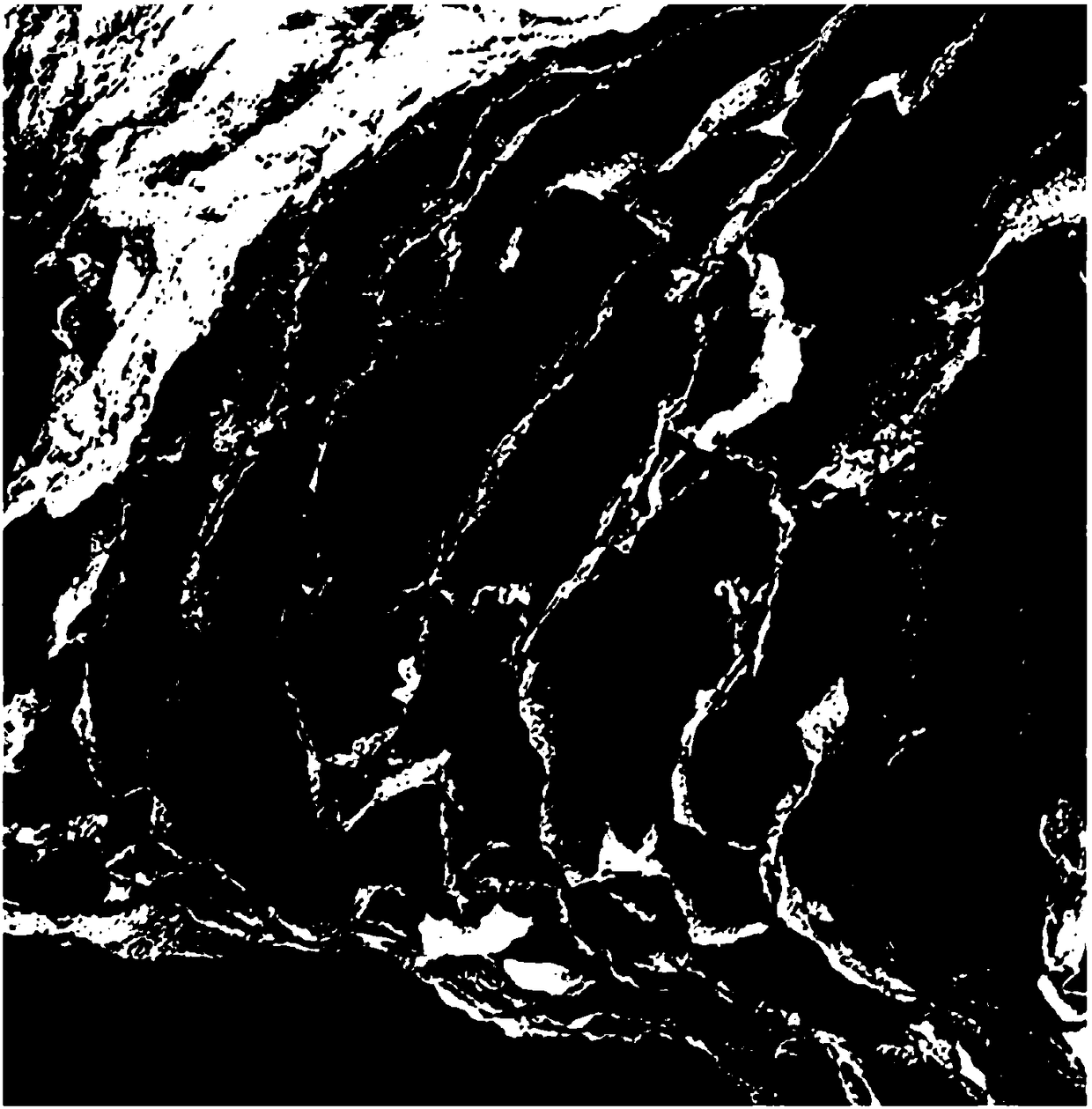

[0036] 2) Preparation of graphene hydrogel: first prepare 10mL concentration of 5mg·mL -1 Graphene oxide solution, at least two of ammonia, thiourea and boric acid are added to the graphene oxide solution to obtain a mixed solution, so that the mass ratio of GO to ammonia, thiourea and boric acid is 1: (0~ 1.14): (0 ~ 0.024): (0 ~ 0.0024), then the mixed solution is added to the reaction kettle and placed in an oven with a temperature of 90 ~ 150 ° C for 6 ~ 14 hours, and the hydrothermal reaction is carried out to obtain graphene water. gel;

[0037] 3) Dialysis of the graphene hydr...

Embodiment 1

[0042] A preparation method for a composite graphene airgel electrode, comprising the following steps:

[0043] 1) Cleaning of the electrode substrate: Cut the titanium sheet into a sample of 1cm×2cm, clean the sample with distilled water, ethanol, and acetone in sequence to remove surface impurities and oil, dry it in a vacuum drying oven, and then put it in nitrogen gloves spare in the box;

[0044] 2) Preparation of graphene hydrogel: first prepare 10mL concentration of 5mg·mL -1 Graphene oxide solution, then ultrasonic and magnetic stirring for 1h each, adding ammonia and thiourea and then magnetically stirring for 1h to obtain a mixed solution, wherein the mass ratio of GO to ammonia and thiourea was 1:1.14:0.012, and the mixed solution was added to the reaction Put it in the kettle and place it in an oven at 120°C, dry it for 6 hours, and obtain a graphene hydrogel after hydrothermal reaction;

[0045] 3) Dialysis of the graphene hydrogel: prepare a mixed dialysate of ...

Embodiment 2

[0051] A preparation method for a composite graphene airgel electrode, comprising the following steps:

[0052] 1) Cleaning of the electrode substrate: Cut the titanium sheet into a sample of 1cm×2cm, clean the sample with distilled water, ethanol, and acetone in sequence to remove surface impurities and oil, dry it in a vacuum drying oven, and then put it in nitrogen gloves spare in the box;

[0053] 2) Preparation of graphene hydrogel: first prepare 10mL concentration of 5mg·mL -1 Graphene oxide solution, then ultrasonic and magnetic stirring for 1h each, adding ammonia water and boric acid and magnetic stirring for 1h to obtain a mixed solution, so that the mass ratio of GO to ammonia water and boric acid was 1:1.14:0.0024, and then the mixed solution was added to the reaction kettle and placed in an oven with a temperature of 120° C. for 6 hours to perform a hydrothermal reaction to obtain a graphene hydrogel;

[0054] 3) Dialysis of the graphene hydrogel: prepare a mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com