Green and environment-friendly water treatment agent and production process thereof

A water treatment agent, green and environmentally friendly technology, applied in water/sewage treatment, adsorbed water/sewage treatment, biological water/sewage treatment, etc., to achieve the effect of good adsorption, fast purification, and reduced migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

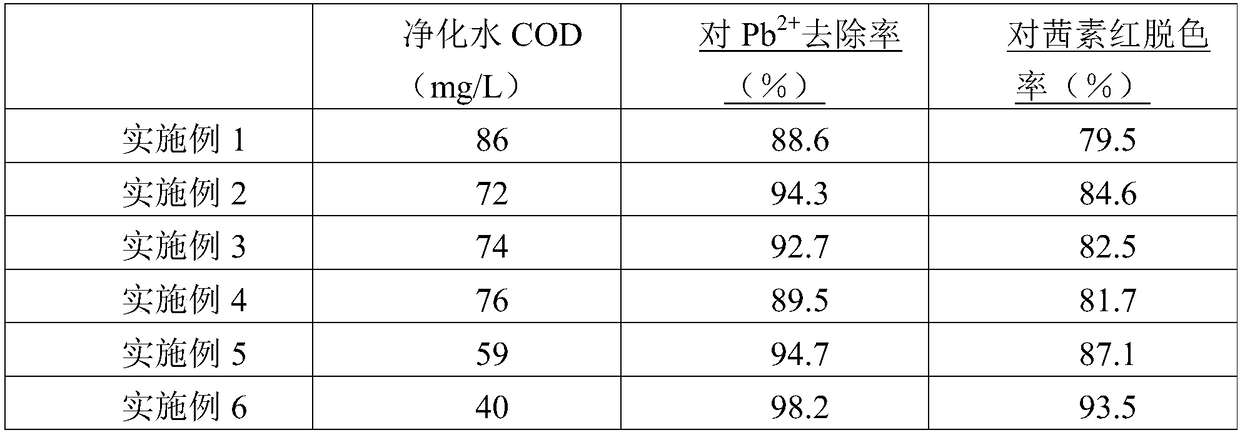

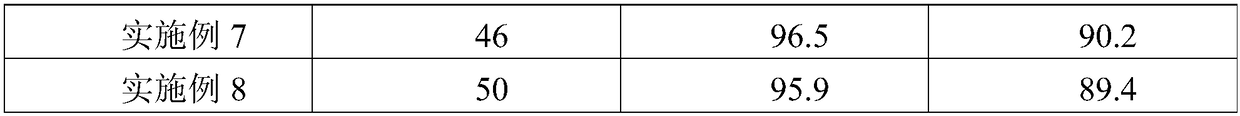

Examples

Embodiment 1

[0059] A kind of green environmental protection type water treatment agent, comprises the raw material preparation of following parts by weight:

[0060] 40 parts of polyacrylamide, 20 parts of polyferric sulfate, 3 parts of ferrous sulfate, 7 parts of polyaluminum chloride, 25 parts of porous ceramic powder, 20 parts of adsorption gel, and 85 parts of water.

[0061] The preparation method of the porous ceramic powder is as follows: attapulgite, talcum powder, bauxite, andalusite, and alumina are mixed in a mass ratio of 6:4:2:1:1, and then passed through a pulverizer to grind powder. 200-mesh sieve to obtain powder, dry the powder at 55°C for 24 hours, heat up to 1000°C at a rate of 5°C / min, calcinate at 1000°C for 1 hour, and then heat up to 1300°C at a rate of 3°C / min. Calcined at 1300° C. for 3 hours, cooled naturally to room temperature, and air-jet milled to obtain porous ceramic powder with a D97 particle size of 50 microns. The preparation method of the adsorption ge...

Embodiment 2

[0064] A kind of green environmental protection type water treatment agent, comprises the raw material preparation of following parts by weight:

[0065] 40 parts of polyacrylamide, 20 parts of polyferric sulfate, 3 parts of ferrous sulfate, 7 parts of polyaluminum chloride, 25 parts of modified porous ceramic powder, 20 parts of adsorption gel, and 85 parts of water.

[0066] The preparation method of the modified porous ceramic powder is as follows: mix attapulgite, talcum powder, bauxite, andalusite, alumina, and a modifier in a mass ratio of 6:4:2:1:1:0.01, After being ground by a pulverizer, pass through a 200-mesh sieve to obtain a powder. Dry the powder at 55°C for 24 hours, raise the temperature to 1000°C at a rate of 5°C / min, calcinate at 1000°C for 1 hour, and then heat it at 3°C / min. The temperature was raised to 1300°C at a rate of 1300°C, calcined at 1300°C for 3 hours, cooled to room temperature naturally, and then airflow pulverized to obtain a modified porous c...

Embodiment 3

[0069] Substantially the same as Example 2, the difference is only that in this Example 3: the modifying agent is the mixture of calcium carbonate, zinc oxide, magnesium acetate tetrahydrate, the mixture of calcium carbonate, zinc oxide, magnesium acetate tetrahydrate The mass ratio is 1:1:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com