Resin Composition

A technology of resin composition and cured product, which is applied in the direction of epoxy resin coatings, coatings, circuits, etc., can solve the problems of poor adhesion strength of metal layers, and achieve the effect of excellent adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

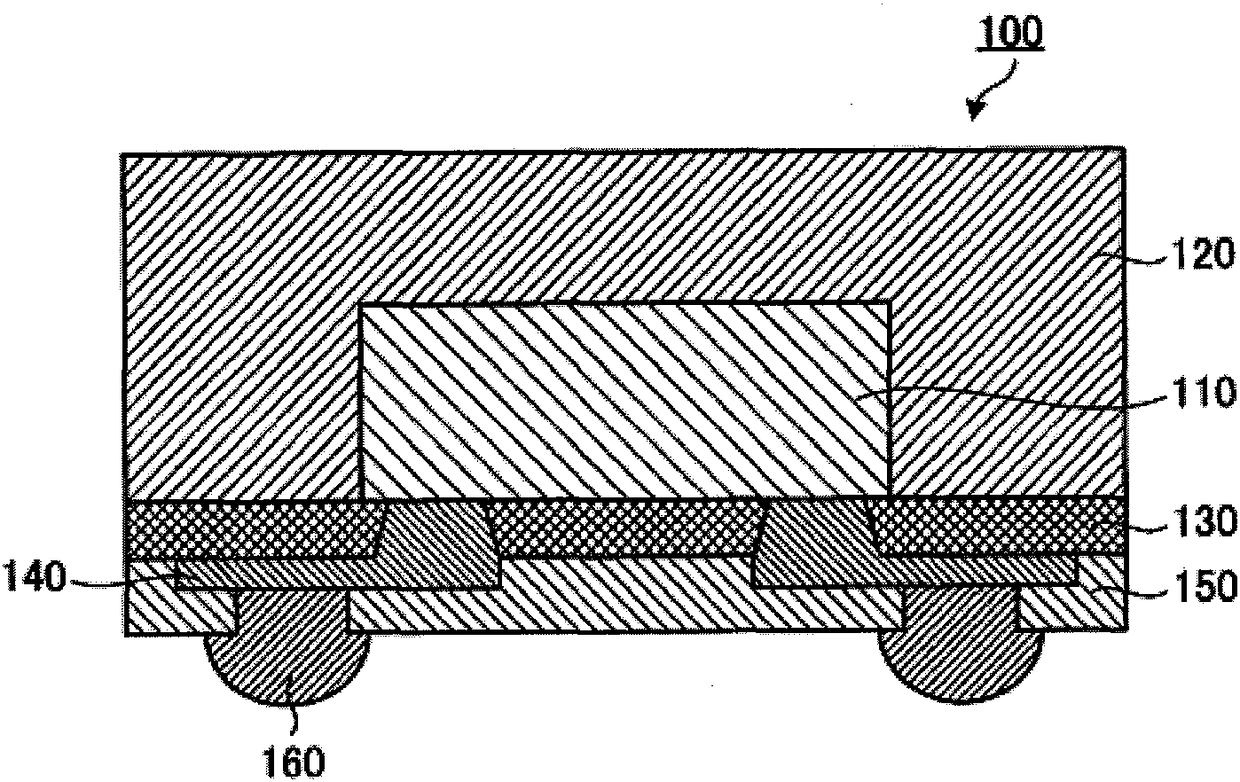

Image

Examples

Embodiment

[0247] Hereafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples. In addition, in the following description, unless otherwise stated, "part" and "%" which show an amount mean "mass part" and "mass %", respectively.

[0248]

[0249] (1) Substrate treatment of inner layer circuit board

[0250] Dip both sides of a glass cloth base epoxy resin double-sided copper-clad laminate (copper foil thickness 18 μm, substrate thickness 0.3 mm, R5715ES manufactured by Panasonic Corporation) with an inner layer circuit formed in CZ8100 manufactured by MEC Co., Ltd. Roughening treatment.

[0251] (2) Lamination of resin sheets

[0252] Using a batch-type vacuum pressure laminator (2-Stage Buildup Laminator (2-stage stack laminator) "CVP700" manufactured by Nikko-Materials Co., Ltd.), the resin sheets produced in Examples and Comparative Examples were laminated inside On both sides of the layered circuit board, the resin c...

Synthetic example 1

[0283]

[0284] 69 g of G-3000 (difunctional hydroxyl-terminated polybutadiene, number average molecular weight = 5047 (GPC method), hydroxyl equivalent = 1798 g / eq., solid content 100% by mass: manufactured by Nippon Soda Co., Ltd.) was mixed in a reaction container , 40 g of Ipsol (イプゾール) 150 (aromatic mixed solvent: manufactured by Idemitsu Petrochemical Co., Ltd.), and 0.005 g of dibutyltin dilaurate were uniformly dissolved. After becoming uniform, the temperature was raised to 50° C., and 8 g of isophorone diisocyanate (manufactured by Evonik Degussa Japan, IPDI, isocyanate group equivalent=113 g / eq.) was further added with stirring, and reacted for about 3 hours. Next, the reactant was cooled to room temperature, and 23 g of cresol novolac resin (KA-1160, manufactured by DIC Corporation, hydroxyl equivalent = 117 g / eq.), diethylene glycol ether acetate (ethyldiglycol acetate, Daicel Corporation) were added thereto. System) 60g, while stirring, the temperature was rais...

Synthetic example 2

[0285]

[0286] In a reaction container, 80 g of polycarbonate diol (number average molecular weight: about 1000, hydroxyl equivalent: 500, non-volatile content: 100%, "C-1015N" manufactured by Kuraray Co., Ltd.) and 0.01 g of dibutyltin dilaurate It was uniformly dissolved in 37.6 g of diethylene glycol monoethyl ether acetate ("diethylene glycol monoethyl ether acetate" manufactured by Daicel). Next, this mixture was heated up to 50 degreeC, and 27.8 g of toluene-2, 4- diisocyanates (isocyanate group equivalent weight: 87.08) were further added, stirring, and it reacted for about 3 hours. Next, the reactant was cooled to room temperature, and 14.3 g of benzophenone tetracarboxylic dianhydride (acid anhydride equivalent: 161.1), 0.12 g of triethylenediamine, and diethylene glycol monoethyl ether acetate (Daicel 84.0 g of "diethylene glycol ethyl ether acetate" manufactured by the company was heated up to 130 degreeC, stirring, and it reacted for about 4 hours. 2250cm confi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com