Monatomic air cathode, battery, electrochemical system and bioelectrochemical system

An air cathode and electrochemical technology, which is applied in the fields of materials, environment and energy, can solve the problems that the performance of cathode, battery and electrochemical system needs to be improved, and achieve the effects of good operation stability, improved performance and high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

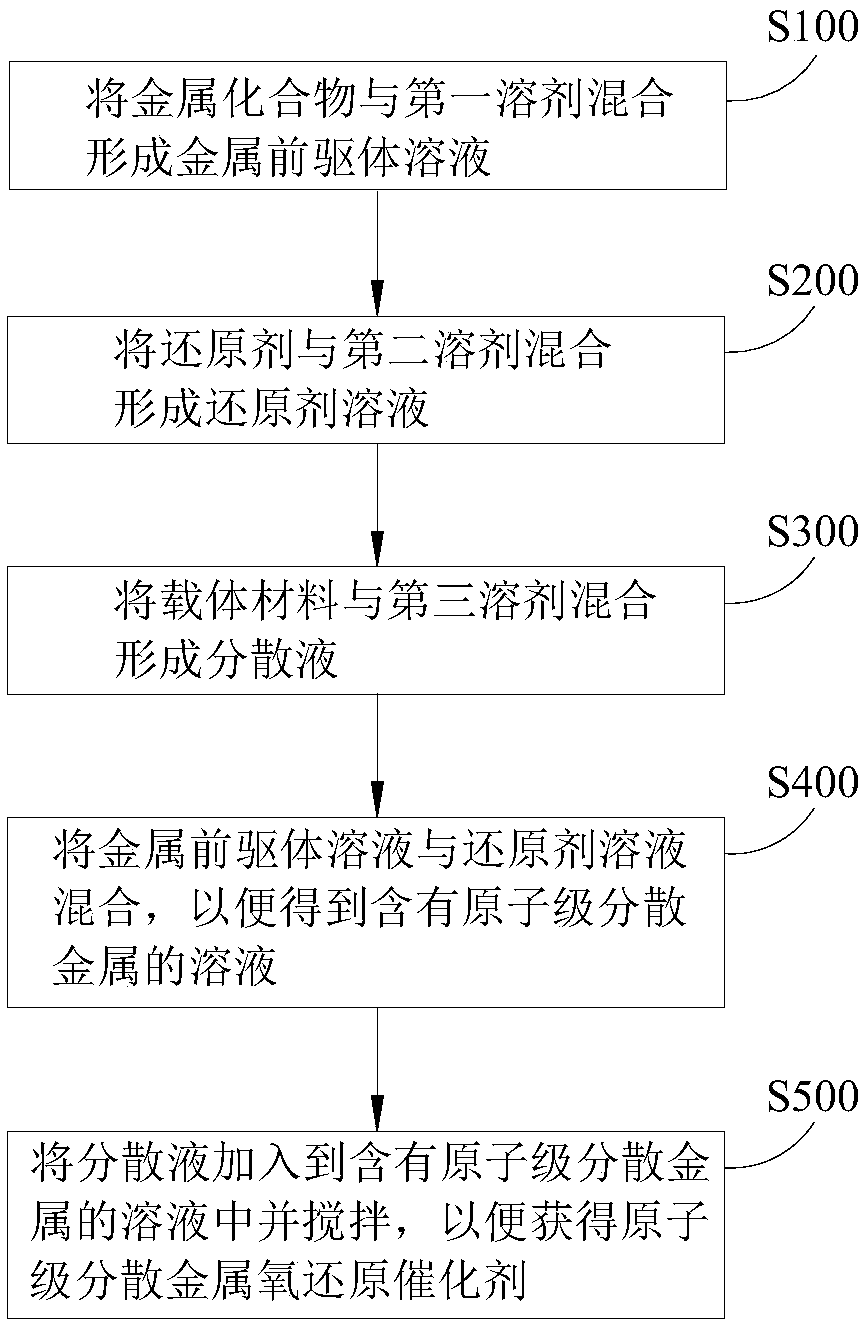

[0099] Example 1: Preparation of atomically dispersed Co catalyst

[0100](1) Configure reaction solution A: 0.01M CoCl 2 solution, the solvent is a water / ethanol mixed solvent with a volume ratio of 1:9; preparation of reducing agent solution B: 5.0M N containing 0.05M KOH 2 h 5 OH hydrazine hydrate solution; preparation of carrier dispersion C: 2.5mg mL -1 Nitrogen-doped mesoporous carbon dispersions.

[0101] (2) Put the above-mentioned reaction solution A and carrier dispersion C in a low-temperature box, cool down to minus 60°C and keep it warm for 30 minutes; use a syringe pump to control 5mL of the above-mentioned CoCl 2 Reaction solution A was dissolved in 0.125mL min -1 Add dropwise to 20mL of reducing solution B at a rate of 20mL; the above mixed liquid continued to react at minus 60°C for 2h, then mixed with 20mL of the above carrier dispersion C, and continued to stir for 3-5 hours.

[0102] (3) The mesoporous carbon-supported single-atom cobalt sample prepare...

Embodiment 2

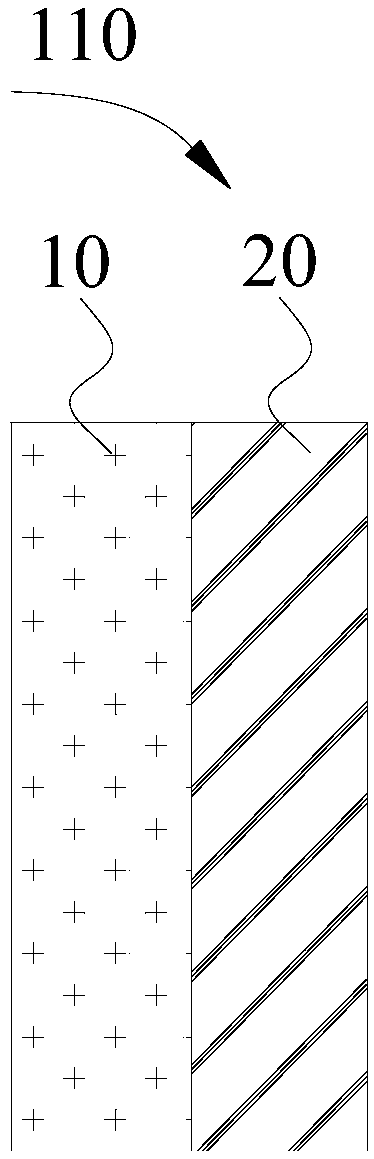

[0104] Example 2: Preparation of a cathode containing an atomically dispersed Co catalyst

[0105] (1) Preparation of diffusion layer: Mix 212mg of carbon black powder with 705.5mg of polytetrafluoroethylene binder (60% by mass fraction), add 1.4mL of absolute ethanol, ultrasonicate in a water bath for 20 seconds, and stir evenly until viscous slime. Place the mud on a plastic flat plate and roll it twice with a roller to make the diffusion layer material mix more evenly, then roll it onto the stainless steel mesh of the support material, press it with a powder tablet press at 4.5MPa for 10min, and then put it on Put it in a muffle furnace at 340°C for 20 minutes, take it out and cool it to room temperature.

[0106] (2) Preparation of catalyst layer and cathode: Weigh 60 mg of the atomically dispersed Co catalyst prepared in Example 1, add 70 μL of polytetrafluoroethylene binder (60% by mass fraction), 388 μL of deionized water, and stir under ultrasonic Mix for 20 seconds,...

Embodiment 3

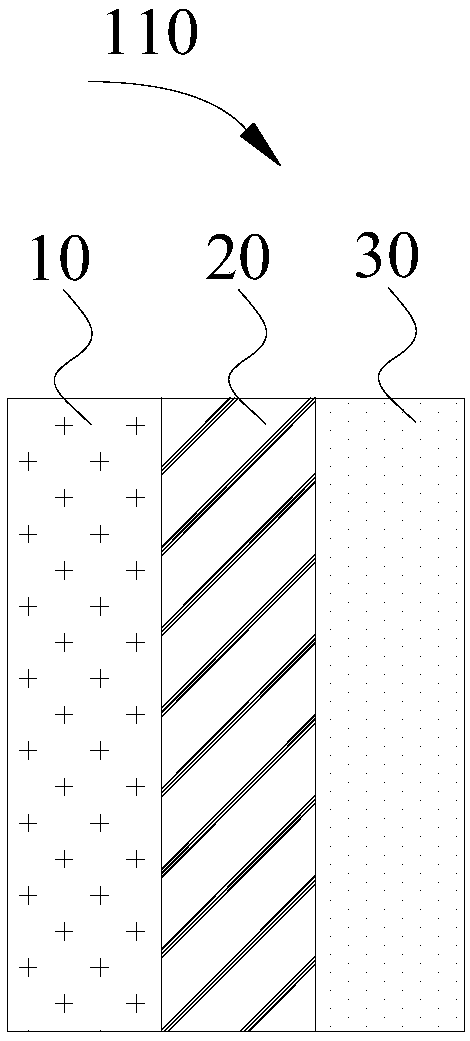

[0107] Embodiment 3: Make the electrochemical system containing atomically dispersed Co catalyst

[0108] The reactor adopts a double-chamber configuration, the anode chamber is 4cm long, and there is a hole with a diameter of 1cm in the upper middle part, which is used to place a platinum electrode as an anode; the cathode chamber is 2cm long, and there is a hole with a diameter of 1cm in the middle, which is used to place Reference electrode, two chambers separated by a cation exchange membrane. Load the cathode containing the atomically dispersed Co catalyst prepared in the titanium sheet and Example 2, then fix it with the cathode baffle plate, tighten and fix it with screws and screws at the four corners of the reactor, and the reactor (i.e. the electrochemical system) is assembled . The electrolyte is 50mM phosphate buffer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com