Liquor making device and application method thereof

A brewing device and brewing room technology, applied in the field of brewing devices, can solve the problems of food quality damage, beer quality impact, retention, etc., and achieve the effect of increasing alcohol concentration, increasing alcohol concentration, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

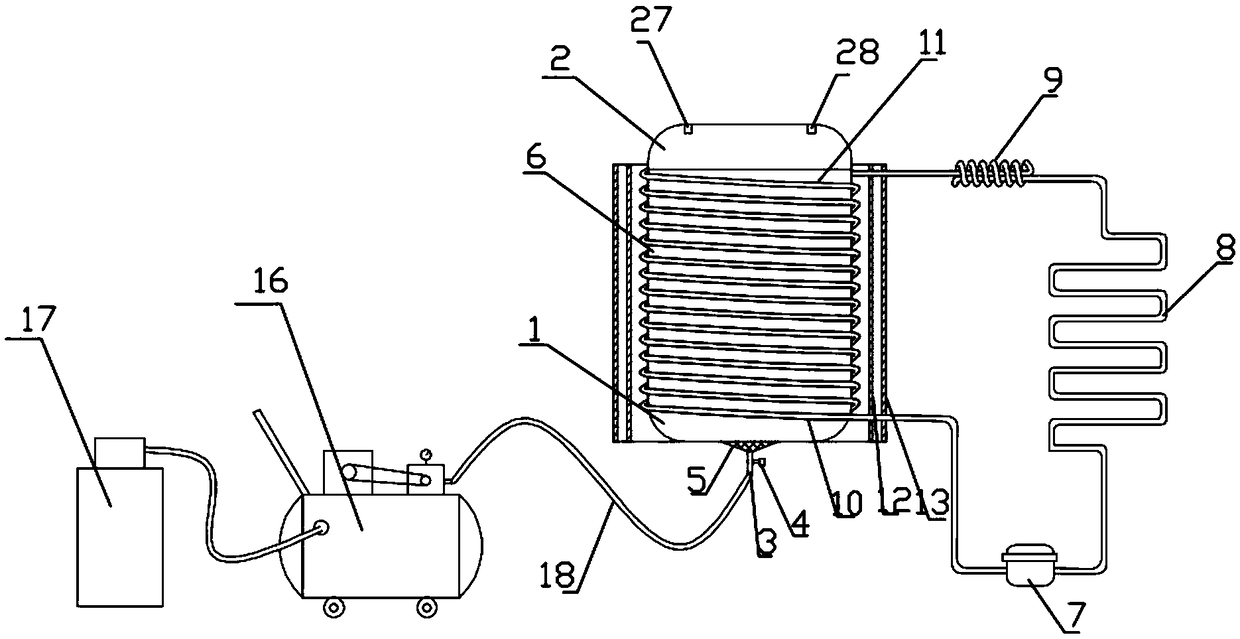

[0047] Such as figure 1 The brewer shown includes a wine grains container 1, a cover body 2, a refrigeration system, a separation system, a conduit 3, a solenoid valve 4 and a filter layer 5; the wine grains container 1 and the lid body 2 are closed to form a seal The brewing chamber 6 is provided with a conduit 3 communicating with it on the outer surface of the brewing chamber 6, and an electromagnetic valve 4 and a filter layer 5 are arranged on the conduit 3.

[0048] The refrigeration system includes a compressor 7, a condenser 8, a throttling device 9, and a first evaporator 10. The exhaust port of the compressor 7 is connected to one end of the condenser 8 by a pipeline, and the other end of the condenser 8 is connected to the throttle by a pipeline. The flow device 9, the throttling device 9 is connected to one end of the first evaporator 10 through a pipeline, and the other end of the first evaporator 10 is finally connected to the suction port of the compressor 7 by ...

Embodiment 2

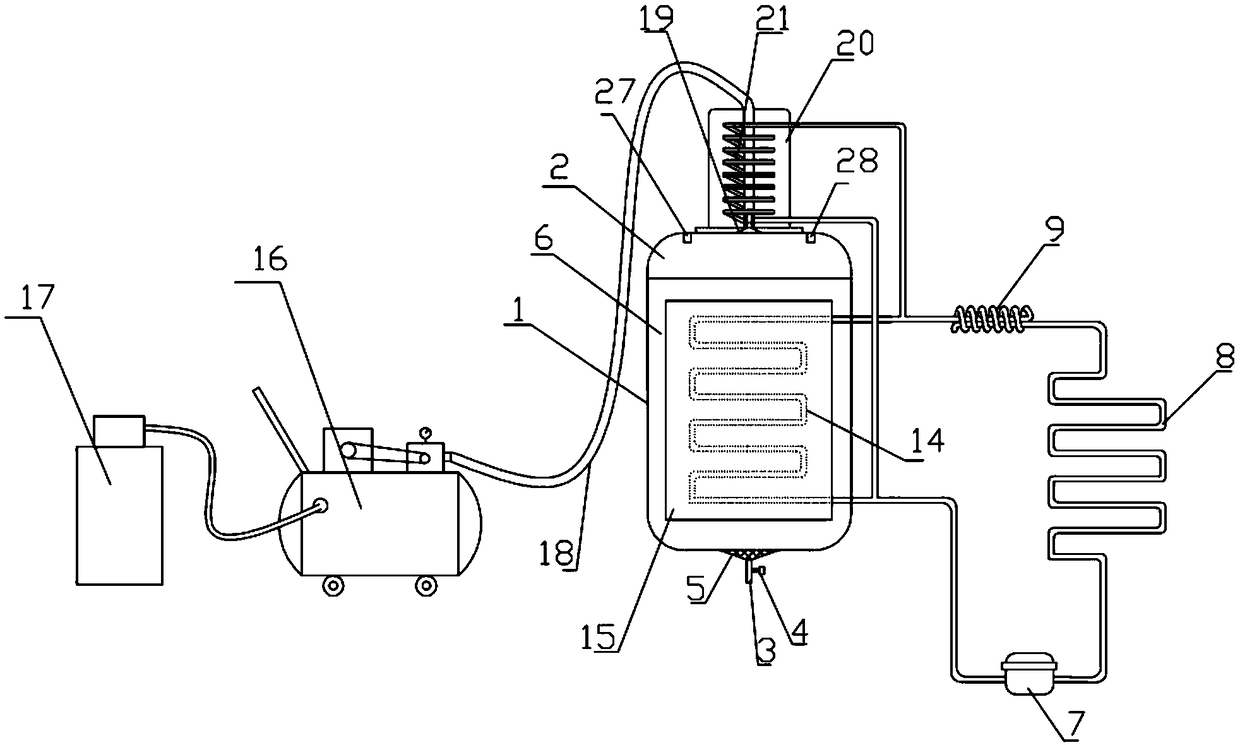

[0053] Such as figure 2 A kind of wine brewer shown, differs from embodiment 1 in that:

[0054] The first evaporator 10 includes a serpentine coil 14 and a film-coated plate 15. The heat exchange section of the serpentine coil 14 is pressed on the film-coated plate 15 through the hot-melt adhesive film on its outer peripheral surface, and the film-coated plate 15 is surrounded by Inside Brewery 6.

[0055] An air nozzle 19 is added above the cover body 2 , and the air outlet pipe 18 communicates with the air nozzle 19 .

[0056] The end of the air outlet pipe 18 connected to the brewing chamber 6 is provided with a condensation chamber 20 , and a second evaporator 21 is arranged in the condensation chamber 20 , and the second evaporator 21 is a spiral condensation pipe surrounding the air outlet pipe 18 .

Embodiment 3

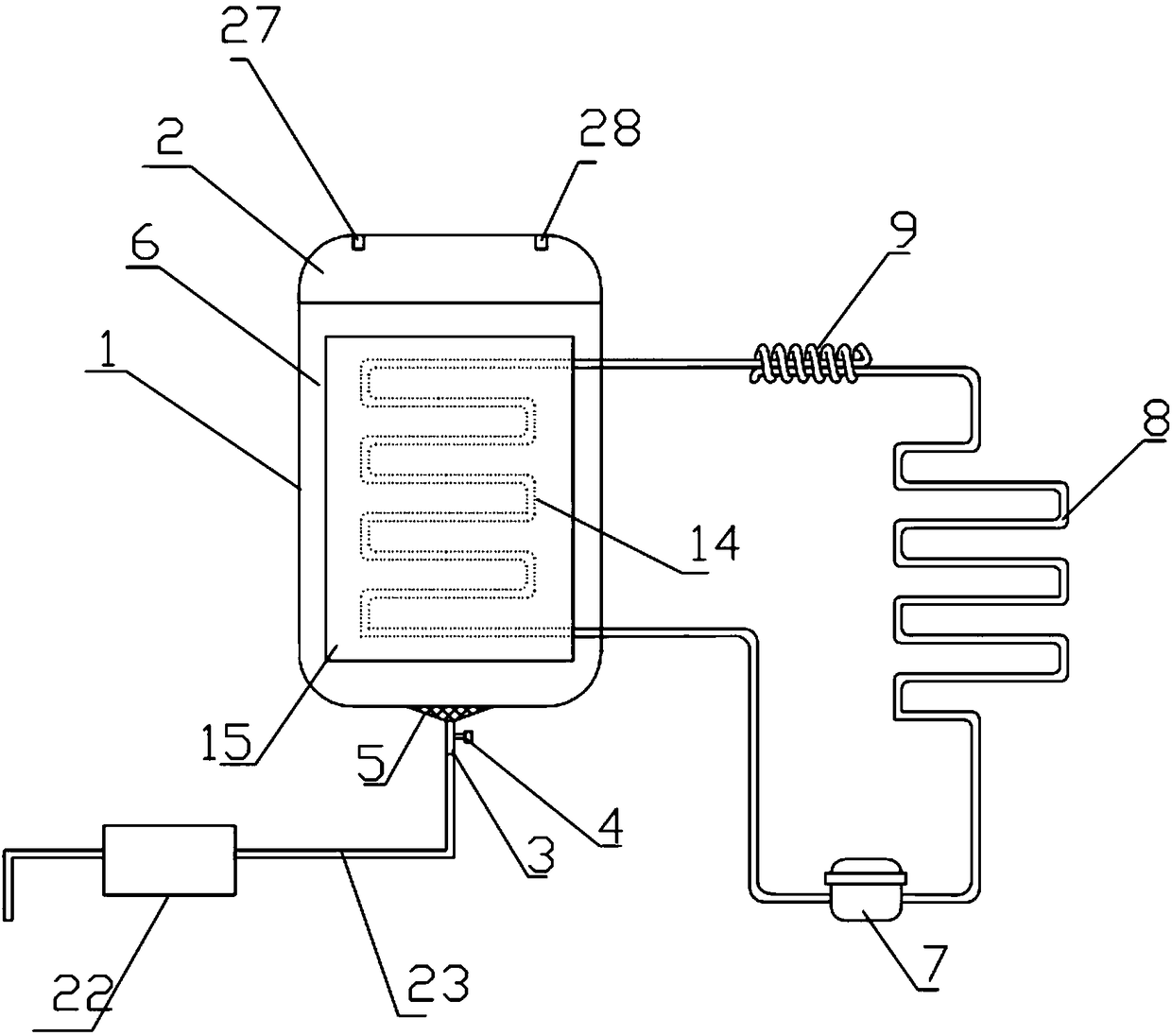

[0058] Such as image 3 A kind of brewer is shown, the separation system in this embodiment is a pumping system, including a water pump 22 and a water pipe 23, the water pipe 23 is detachably connected to the conduit 3 connected to the brewing chamber 6, and the water pump 22 provides power to make the brewing chamber 6 The liquid that melts earlier in the interior is drawn out from water suction pipe 23.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com