Aluminum nitride dispersion strengthened powder metallurgy aluminum high speed steel and preparation method thereof

A powder metallurgy and dispersion strengthening technology, applied in the field of powder metallurgy high-speed steel, can solve the problems of material toughness deterioration, refractory melting and atomization, and achieve the effects of avoiding chain distribution, inhibiting growth, and refining the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

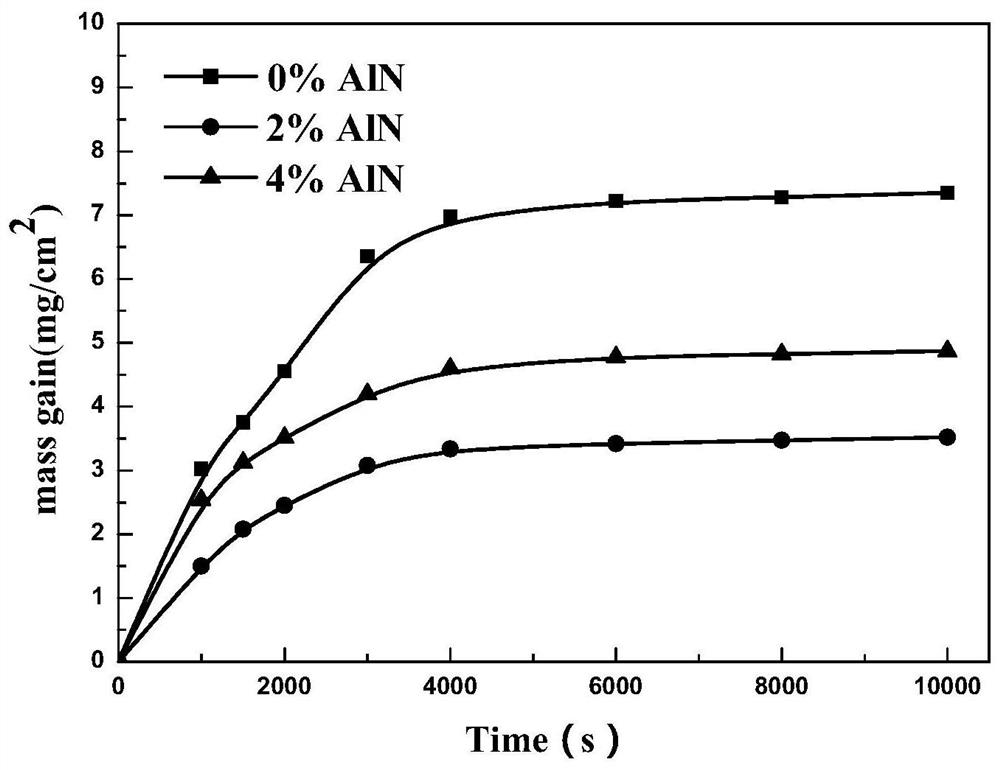

[0032] 1) 6.39wt.% WC powder, 5.31wt.% Mo2C powder, 4.62wt.% Cr3C2 powder, 3.71wt.% VC powder with a particle size of 0.05-10 microns and an oxygen content less than 0.1%, 8.0wt.% Co powder, 0.05wt.% AlN powder, 1.21wt.% carbon powder, and 70.71wt.% carbonyl iron powder were mixed and wet-milled in a roller ball mill. The ball milling medium was absolute ethanol, and the cemented carbide ball was a ball. The material ratio is 4:1, the ball milling time is 24 hours, and the powder mixture slurry is prepared;

[0033] 2) Stir and dry the mixed powder slurry obtained in step 1 in a stirring dryer at a temperature of 75°C until the liquid is completely evaporated, then put the powder into a sieve granulator, add 1% stearic acid and an appropriate amount of alcohol for drying Sieve granulation;

[0034] 3) Press the mixed powder under an automatic press at 300Mpa, hold the pressure for 30s, then carry out hydrogen degreasing, deoxygenation and pre-calcination, and then carry out p...

Embodiment 2

[0038] 1) 10.66wt.% WC powder, 5.31wt.% Mo2C powder, 3.46wt.% Cr3C2 powder, 11.74wt.% VC powder, 9.0wt.% with particle size of 0.05-10 microns and oxygen content less than 0.1% Co powder, 0.25wt.% AlN powder, 3.2wt.% carbon powder, and 56.23wt.% carbonyl iron powder are mixed and wet-milled in a drum-type ball mill. The material ratio is 3:1, the ball milling time is 26 hours, and the powder mixture slurry is prepared;

[0039] 2) Stir and dry the mixed powder slurry obtained in step 1 in a stirring dryer at a temperature of 80°C until the liquid is completely evaporated, then put the powder into a sieve granulator, add 1% stearic acid and an appropriate amount of alcohol for drying Sieve granulation;

[0040] 3) Press the mixed powder under the automatic press at 280Mpa, hold the pressure for 30s, then carry out hydrogen degreasing, deoxidation and pre-calcination, and then carry out pressure sintering.

[0041] 4) Heat treatment: The heat treatment process is: first stage ...

Embodiment 3

[0044] This embodiment takes the following technical solutions:

[0045] 1) 2.13wt.% WC powder, 3.19wt.% Mo2C powder, 9.23wt.% Cr3C2 powder, 6.18wt.% VC powder, 2.0wt.% with particle size of 0.05-10 microns and oxygen content less than 0.1% Co powder, 5.0wt.% AlN powder, 0.8wt.% carbon powder and 71.47wt.% carbonyl iron powder were wet-milled and mixed in a roller ball mill. The material ratio is 2:1, the ball milling time is 27 hours, and the powder mixture slurry is prepared;

[0046] 2) Stir and dry the mixed powder slurry obtained in step 1 in a stirring dryer at a temperature of 75°C until the liquid is completely evaporated, then add 1% stearic acid and an appropriate amount of alcohol for sieving and granulation;

[0047] 3) Press the mixed powder under an automatic press at 400Mpa, hold the pressure for 30s, then carry out hydrogen degreasing, deoxidation and pre-calcination, and then carry out pressure sintering, the sintering temperature is 1130°C, heat preservation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com