Micro-nano type hollow-structured double-metal catalyst and preparation method and application thereof

A technology of bimetallic catalysts and hollow structures, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low utilization of metal active sites and few edge active sites, and achieve Improve the utilization rate of metal raw materials, the coke suppression effect is good, and the effect of simplifying the pre-vulcanization step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

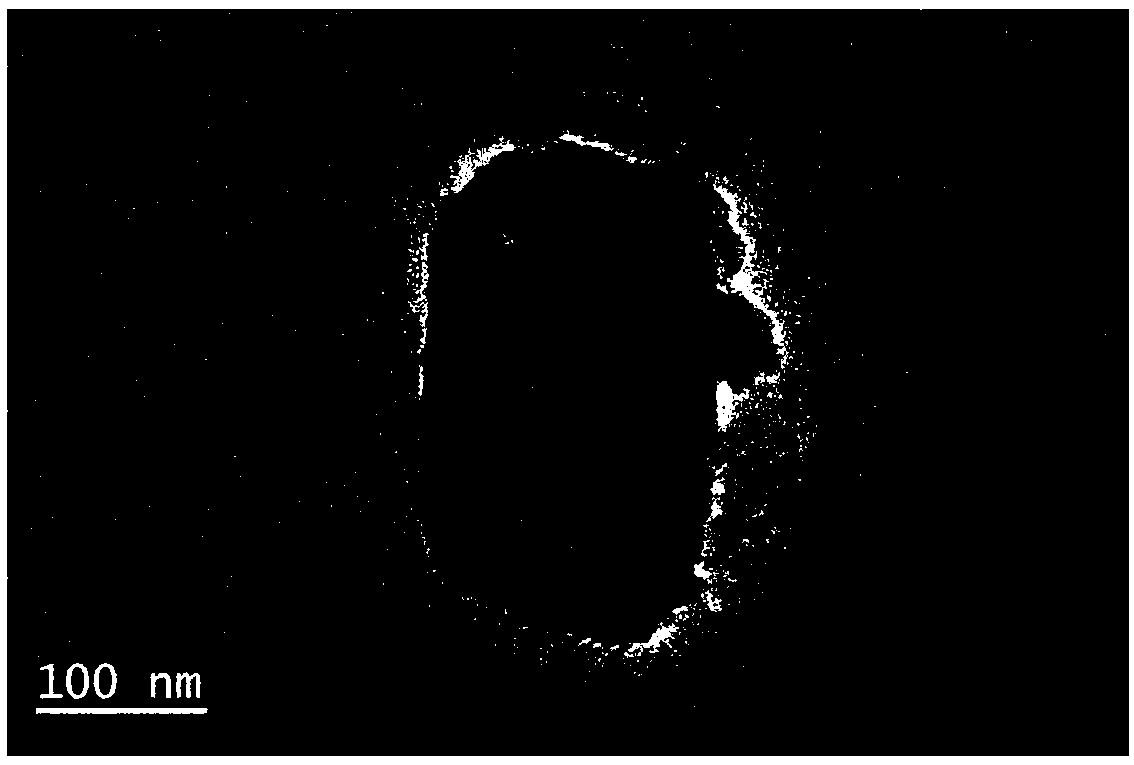

[0032] This example provides a micro-nano hollow structure bimetallic catalyst Ni-MoS 3 , the active component of the catalyst is the sulfided substance of molybdenum and nickel, the molar ratio of molybdenum to nickel is 1:1, and the sum of the mass fractions of molybdenum and nickel in the catalyst is 32.35%, and its preparation method is as follows:

[0033] (1) Take 10.0g of ammonium molybdate and pour it into 30ml of ammonia water, stir at 45°C until the ammonium molybdate is completely dissolved, after heating up to 65°C, add 50ml of ammonium sulfide aqueous solution, react for 100min, then cool and crystallize to product 1;

[0034] (2) Take 2.8g of polyvinylpyrrolidone (PVP), 1.3g of nickel acetate tetrahydrate and 200ml of absolute ethanol in a container, stir and reflux at a reaction temperature of 85°C for 6 hours, then centrifuge the product 2;

[0035] (3) 50 mg of product 2 was dissolved in 25 ml of isopropanol, and 220 mg of product 1 was dissolved in 480 ml of ...

Embodiment 2

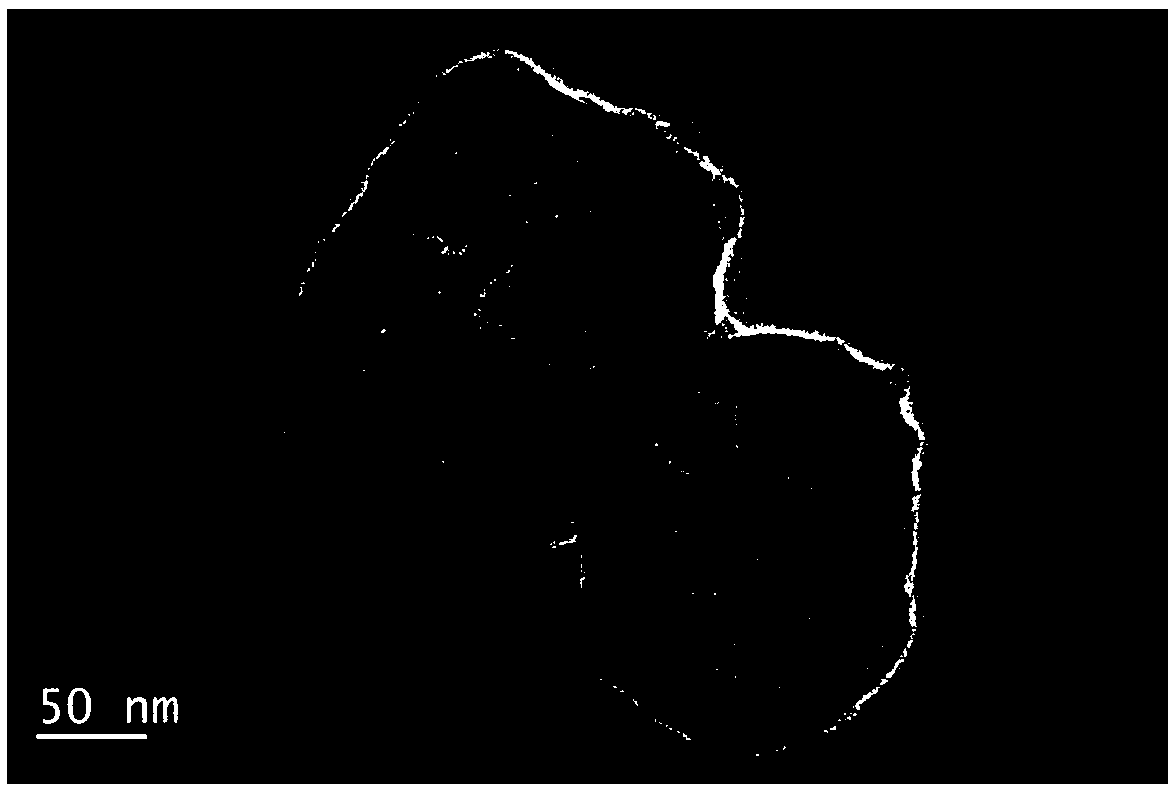

[0039] This example provides a micro-nano hollow structure bimetallic catalyst Ni-MoS 3 , the catalyst active component is the sulfide state substance of molybdenum and nickel, the molar ratio of molybdenum to nickel is 1:3, and the mass fraction of molybdenum and nickel in the catalyst is 34.67%, and its preparation method is as follows:

[0040] (1) Take 10.0g of ammonium molybdate and pour it into 20ml of ammonia water, stir at 45°C until the ammonium molybdate is completely dissolved, heat up to 68°C, add 150ml of hydrogen sulfide gas, react for 60min, then cool and crystallize to product 1;

[0041] (2) Take 2.8g of polyvinylpyrrolidone (PVP), 1.96g of nickel nitrate and 200ml of absolute ethanol in a container, stir and reflux at a reaction temperature of 90°C for 4 hours, then centrifuge the product 2;

[0042] (3) 50 mg of product 2 was dissolved in 18 ml of absolute ethanol, and 220 mg of product 1 was dissolved in 550 ml of deionized water. Pour the product 1 soluti...

Embodiment 3

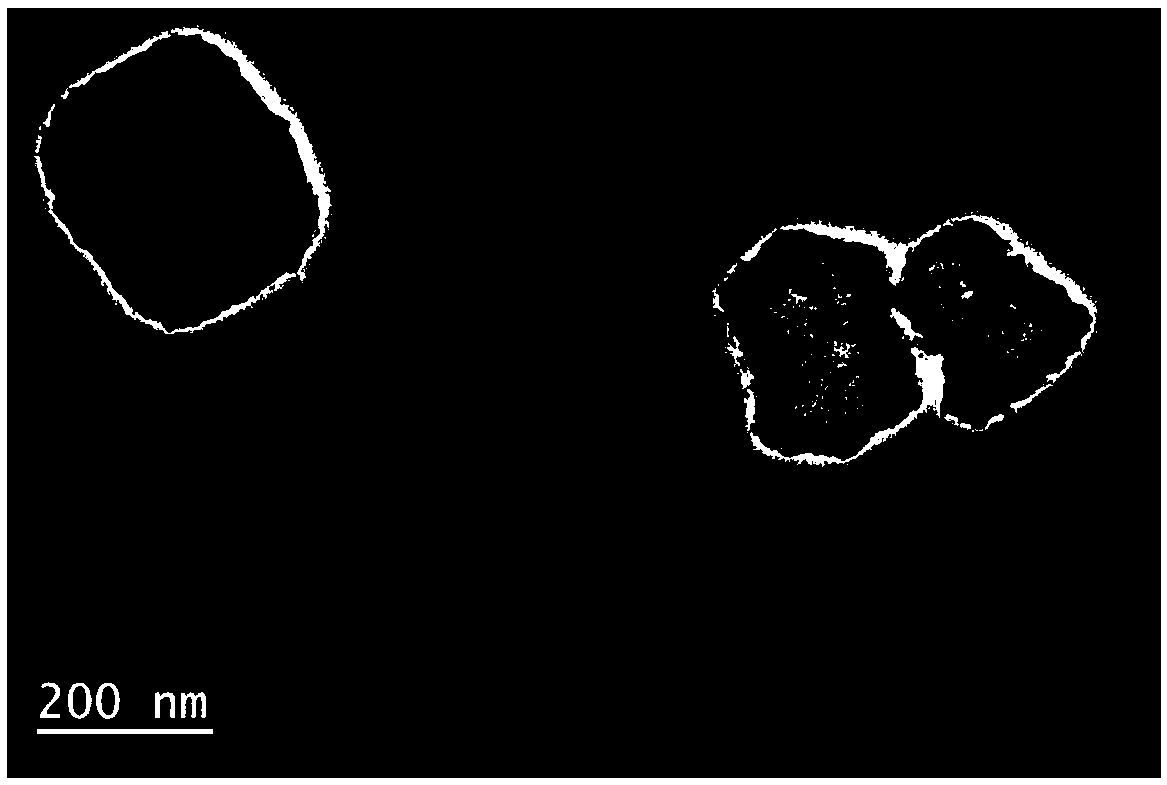

[0046] This example provides a micro-nano hollow structure bimetallic catalyst Ni-MoS 3 , the catalyst active ingredient is molybdenum and nickel sulfide substances, the molar ratio of molybdenum to nickel is 1.5:1, the mass fraction of molybdenum and nickel in the catalyst is 40.56%, and its preparation method is as follows:

[0047] (1) Take 10.0g of ammonium molybdate and pour it into 40ml of ammonia water, stir at 45°C until the ammonium molybdate is completely dissolved, after heating up to 60°C, add 150ml of ammonium sulfide aqueous solution, react for 120min, then cool and crystallize to obtain product 1;

[0048] (2) Take 2.8g of polyvinylpyrrolidone (PVP), 0.84g of nickel chloride and 200ml of absolute ethanol in a container, stir and reflux at a reaction temperature of 65°C for 8 hours, and centrifuge the product 2;

[0049] (3) 50 mg of product 2 was dissolved in 20 ml of ethylene glycol, and 220 mg of product 1 was dissolved in 330 ml of deionized water. Pour the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com