Preparation method and application of cobalt phosphide porous nanowire/stainless steel composite electrocatalyst

A porous nanowire and electrocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of limiting the wide application of electrocatalytic hydrogen evolution, consuming large electric energy, scarcity, etc., to achieve excellent The effect of electrocatalytic hydrogen evolution performance, widening source, good stability and persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of cobalt phosphide porous nanowire / stainless steel composite hydrogen evolution electrocatalyst, the specific steps are as follows:

[0033] A. Stainless steel pretreatment, cut 316 stainless steel (316-SS) into a size of 1.5×2 cm, put it in the prepared 1M HCl solution for ultrasonic treatment for 1 hour, then put it in acetone for ultrasonic treatment for 1 hour, finally wash with water, alcohol Washing and drying to obtain pretreated Type 316 stainless steel,

[0034] Using carbon cloth as the base material for comparison, cut the carbon cloth into 1.5×2cm, and dry it with acetone, ethanol, and water respectively to obtain the pretreated carbon cloth;

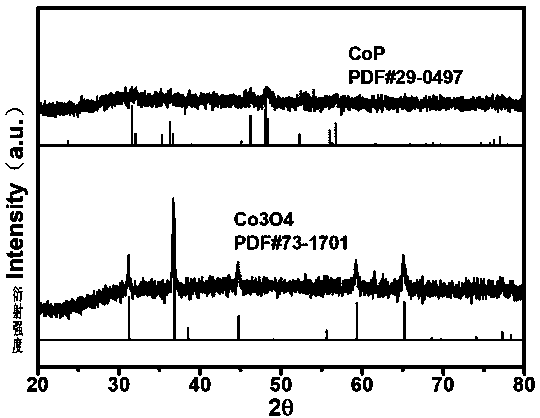

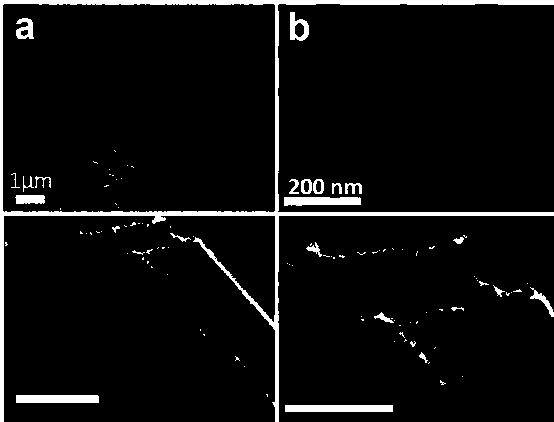

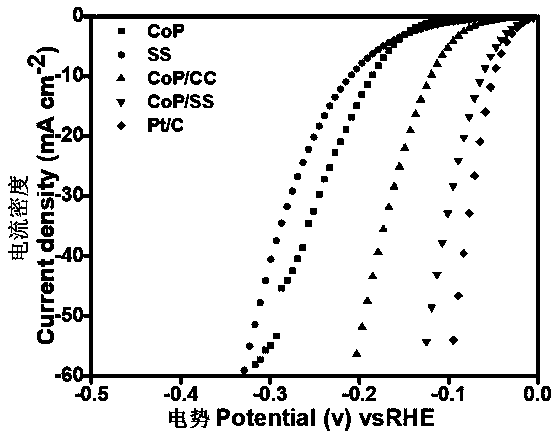

[0035] B. Synthesize the precursor of CoP / SS by hydrothermal method, weigh 10mmol of urea, 4mmol of ammonium fluoride, and 2mmol of CoCl 2 ·6H 2 O is dissolved in the deionized water of 40ml volume, then supersonic 15min forms the homogeneous and stable solution, it is transferred in the polyte...

Embodiment 2

[0045] A preparation method of cobalt phosphide porous nanowire / stainless steel composite hydrogen evolution electrocatalyst, the specific steps are as follows:

[0046] A. Pretreatment of stainless steel, cut 316 stainless steel (316-SS) into a size of 1.5×2 cm, put it into the prepared 1.5M HCl solution for ultrasonic treatment for 1.5h, then put it into acetone for ultrasonic treatment for 1.5h, Finally, wash with water, wash with alcohol, and dry to obtain pretreated Type 316 stainless steel;

[0047] B. Synthesize the precursor of CoP / SS by hydrothermal method, weigh 11mmol of urea, 5mmol of ammonium fluoride, and 3mmol of CoCl 2 ·6H 2 O is dissolved in the deionized water of 42ml volume, then supersonic 15min forms the homogeneous and stable solution, it is transferred to the polytetrafluoroethylene (PTFE) lined autoclave of 50ml, puts the stainless steel that handles into the kettle, at 140 Hydrothermal reaction at ℃ for 8 hours, washed with deionized water, and dried...

Embodiment 3

[0050] A preparation method of cobalt phosphide porous nanowire / stainless steel composite hydrogen evolution electrocatalyst, the specific steps are as follows:

[0051] A. Pretreatment of stainless steel, cut 316 stainless steel (316-SS) into a size of 1.5×2 cm, put it in the prepared 2M HCl solution for ultrasonic treatment for 2 hours, then put it in acetone for ultrasonic treatment for 2 hours, finally wash with water, alcohol Washing and drying to obtain pretreated 316 type stainless steel;

[0052] B. The precursor of CoP / SS is synthesized by hydrothermal method, weighing 12mmol of urea, 6mmol of ammonium fluoride, and 4mmol of CoCl 2 ·6H 2 O is dissolved in the deionized water of 45ml volume, then supersonic 15min forms the homogeneous and stable solution, it is transferred to the polytetrafluoroethylene (PTFE) lined autoclave of 50ml, puts the stainless steel that handles into the kettle, at 150 Hydrothermal reaction at ℃ for 10 h, washed with deionized water, and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com