A permeable and cross-linked combined coating for anticorrosion of cooling towers

A cooling tower and cross-linking technology, which is applied in the field of permeable cross-linking combined coatings, can solve the problems of inability to exert synergistic effect of coatings, poor coating adhesion, poor anti-corrosion effect, etc., and achieve good dynamic crack resistance and low elasticity The effect of modulus and ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

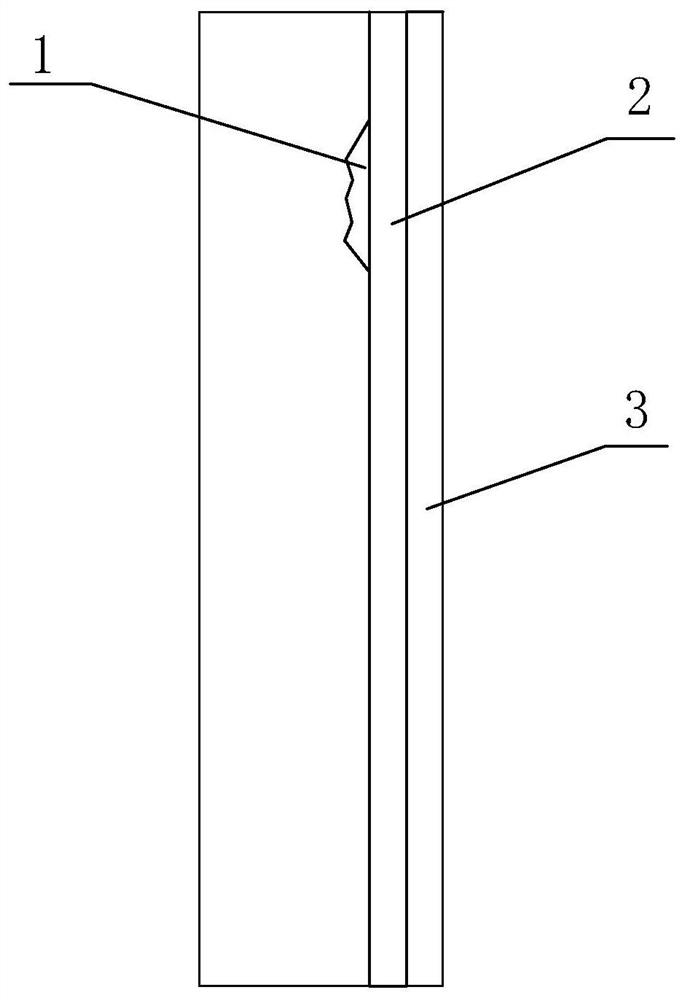

[0061] The invention relates to a permeable cross-linked combined coating for anticorrosion of cooling towers, which comprises: base surface repair material, primer coating and surface coating in the order of coating.

[0062] The base surface repair material comprises: 50wt% of quartz powder, 45wt% of Portland cement and 5wt% of acrylate / acrylamine / acrylate terpolymer.

[0063] The primer comprises: 50wt% of Portland cement slag, 10wt% of quartz sand and 40wt% of quartz powder.

[0064] The surface coating is divided into an inner wall surface coating and an outer wall surface coating.

[0065] The inner wall surface coating comprises: 22wt% of bisphenol A, 45wt% of epichlorohydrin resin, 17wt% of 3-aminomethyl-3,5,5-trimethylcyclohexylamine, and 16wt% of polyamide.

[0066] The outer wall surface coating comprises: 30 wt% of acrylate polymer, 25 wt% of calcium carbonate, 20 wt% of titanium dioxide and 25 wt% of water.

[0067] When used, the external emulsion used in conju...

Embodiment 2

[0070] The invention relates to a permeable cross-linked combined coating for anticorrosion of cooling towers, which comprises: base surface repair material, primer coating and surface coating in the order of coating.

[0071] The base surface repair material includes 45 wt% of quartz powder, 50 wt% of Portland cement and 5 wt% of acrylate / acrylamine / acrylate terpolymer.

[0072] The primer comprises 45wt% of Portland cement slag, 12wt% of quartz sand and 43wt% of quartz powder.

[0073] The surface coating is divided into an inner wall surface coating and an outer wall surface coating.

[0074] The inner wall surface coating includes 22wt% of bisphenol A, 45wt% of epichlorohydrin resin (MW<700), 17wt% of 3-aminomethyl-3,5,5-trimethylcyclohexylamine, and 16wt% of polyamide %.

[0075] The outer wall surface coating comprises 25 wt% of acrylate polymer, 30 wt% of calcium carbonate, 15 wt% of titanium dioxide and 30 wt% of water.

[0076] When in use, the cured thickness of t...

Embodiment 3

[0078] The invention relates to a permeable cross-linked combined coating for anticorrosion of cooling towers, which comprises: base surface repair material, primer coating and surface coating in the order of coating.

[0079] The base surface repair material includes 55 wt% of quartz powder, 40 wt% of Portland cement and 5 wt% of acrylate / acrylamine / acrylate terpolymer.

[0080] The primer comprises 55 wt% of Portland cement slag, 8 wt% of quartz sand and 37 wt% of quartz powder.

[0081] The surface coating is divided into an inner wall surface coating and an outer wall surface coating.

[0082]The inner wall surface coating includes 23wt% of bisphenol A, 47wt% of epichlorohydrin resin (MW<700), 15wt% of 3-aminomethyl-3,5,5-trimethylcyclohexylamine, and 15wt% of polyamide %.

[0083] The outer wall surface coating comprises 35wt% of acrylate polymer, 20wt% of calcium carbonate, 25wt% of titanium dioxide and 20wt% of water.

[0084] When in use, the cured thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com