Waterless liquid coolant for engine under extreme conditions and preparation method thereof

A technology of extreme conditions and engines, applied in the direction of chemical instruments and methods, metal material coating technology, heat exchange materials, etc., can solve inconvenience and other problems, achieve high conductivity, good corrosion performance, and prevent electrochemical corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Weigh 23Kg of dipropylene glycol and 48Kg of propylene glycol and stir evenly; then add 16Kg of imidazole ionic liquid into it, and use a magnetic stirrer to fully stir for about 1 hour until uniform; add 1.5kg of silicone defoamer, and fully stir until completely dissolved ; Then add 0.5kg tolyltriazole, 0.5kg sodium nitrite, 0.8kg sebacic acid, 0.7kg caprylic acid, 0.3kg citric acid, 0.8kg sodium metasilicate, 0.7kg ammonium molybdate, and heat to 73°C -77°C, fully stirred until completely dissolved; finally add 7.5Kg viscosity reducer, fully stir until completely dissolved, that is, the finished product of anhydrous coolant for engine under extreme conditions of the present invention, its freezing point is -67.5°C, The boiling point is 253°C.

Embodiment 2

[0103] Weigh 25Kg of dipropylene glycol and 47Kg of propylene glycol and stir evenly; then add 17Kg of imidazole-based ionic liquid to it, then add 2.2Kg of imidazole-based ionic liquid into it, and stir fully with a magnetic stirrer for about 1 hour until uniform; add 1.8kg of organic silicon Defoamer, fully stirred until completely dissolved; then add 0.8kg tolyltriazole, 0.5kg sodium nitrite, 0.5kg sebacic acid, 0.7kg octanoic acid, 0.4kg citric acid, 0.6kg sodium metasilicate , 0.8kg ammonium molybdate, fully stirred, until fully dissolving; Add 7.2kg viscosity reducer at last, fully stir, until fully dissolving, promptly obtain the anhydrous cooling liquid finished product of motor under extreme conditions of the present invention, and its freezing point is- 65.5°C, the boiling point is 254°C.

Embodiment 3

[0105] Weigh 25Kg of dipropylene glycol and 45Kg of propylene glycol and stir evenly; then add 16Kg of imidazole ionic liquid into it, and stir fully with a magnetic stirrer for about 1 hour until uniform; add 1.0kg of silicone defoamer, and fully stir until completely dissolved ; Add 0.8kg tolyltriazole, 0.5kg sodium nitrite, 0.5kg sebacic acid, 0.7kg octanoic acid, 0.4kg citric acid, 0.6kg sodium metasilicate, 0.8kg ammonium molybdate successively, fully stir until Completely dissolve; finally add 6.8kg of viscosity reducer, fully stir until completely dissolved, that is, obtain the finished product of water-free coolant for engine under extreme conditions of the present invention, its freezing point is -69 ℃, boiling point is 255 ℃.

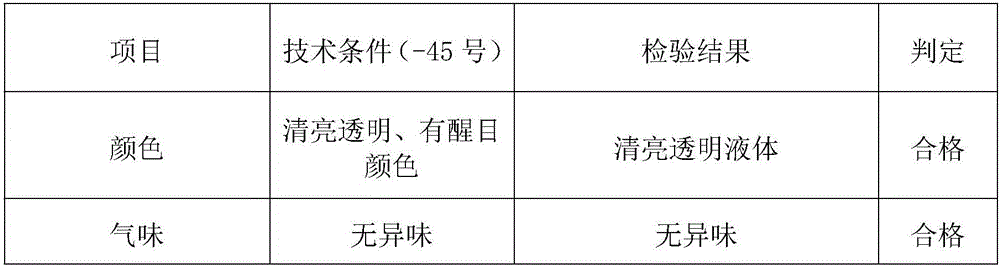

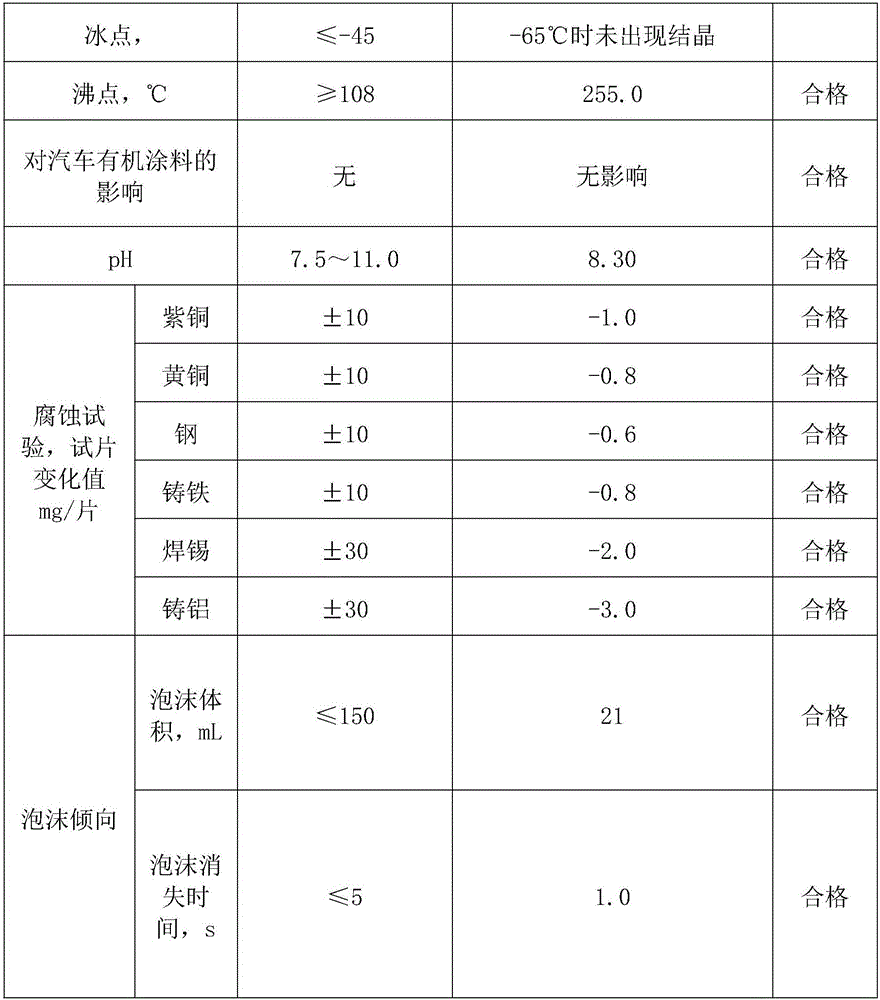

[0106] After the product of the present invention is sent to the Chinese People's Liberation Army Oil Plant and Oil Plant Equipment Inspection and Test Center for inspection, the inspection report is as follows, and part of the inspection data ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com