Preparation method and application of modified carbon fiber microelectrode

A micro-electrode and modified carbon technology, which is applied in the direction of material electrochemical variables, material analysis by electromagnetic means, and measurement devices, can solve the problems of low detection sensitivity, achieve high detection sensitivity, increase specific surface area, and low preparation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a modified carbon fiber microelectrode, comprising the following steps:

[0032] 1) Surface activation: Place a bundle of unsized T700 carbon fibers in absolute ethanol and ultrapure water in sequence, ultrasonically wash them for 5 minutes, and then place them in a nitric acid solution with a concentration of 65% to surface the carbon fibers by liquid phase oxidation. Activation, the activation temperature is 100°C, the time is 2h, and then the nitric acid on the surface of the activated carbon fiber is neutralized with 0.1mol / L NaOH, and the carbon fiber is cleaned with deionized water;

[0033] 2) Coating catalyst: preparing catalyst Ni(NO 3 ) 2 ·6H 2 Immerse the activated carbon fiber in an ethanol solution with an O concentration of 0.05mol / L, take it out after 1 hour, and dry it at 80°C for 30 minutes;

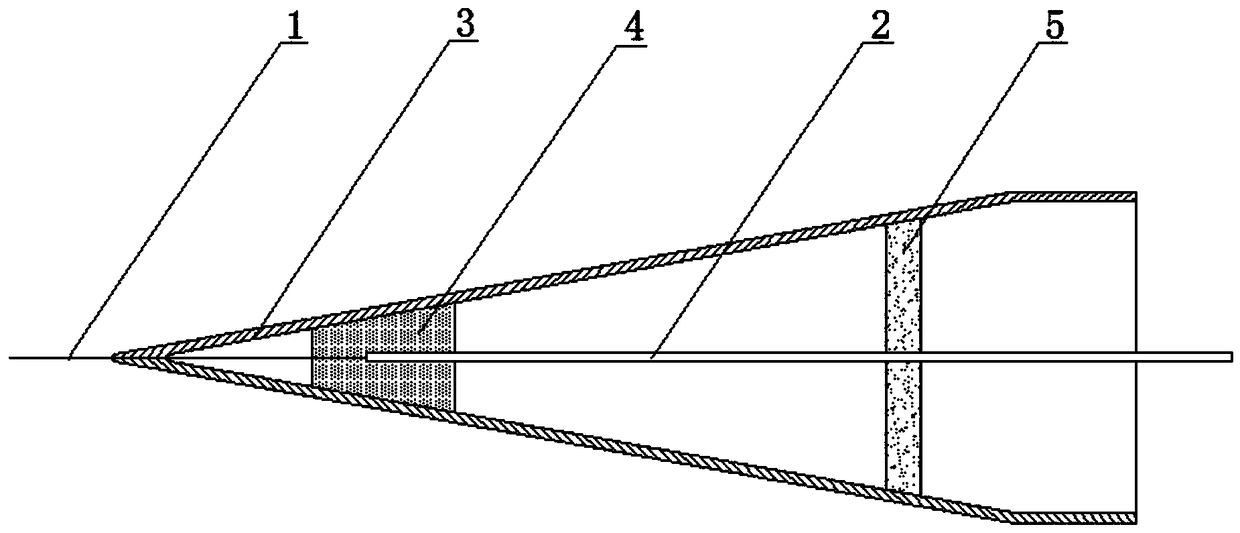

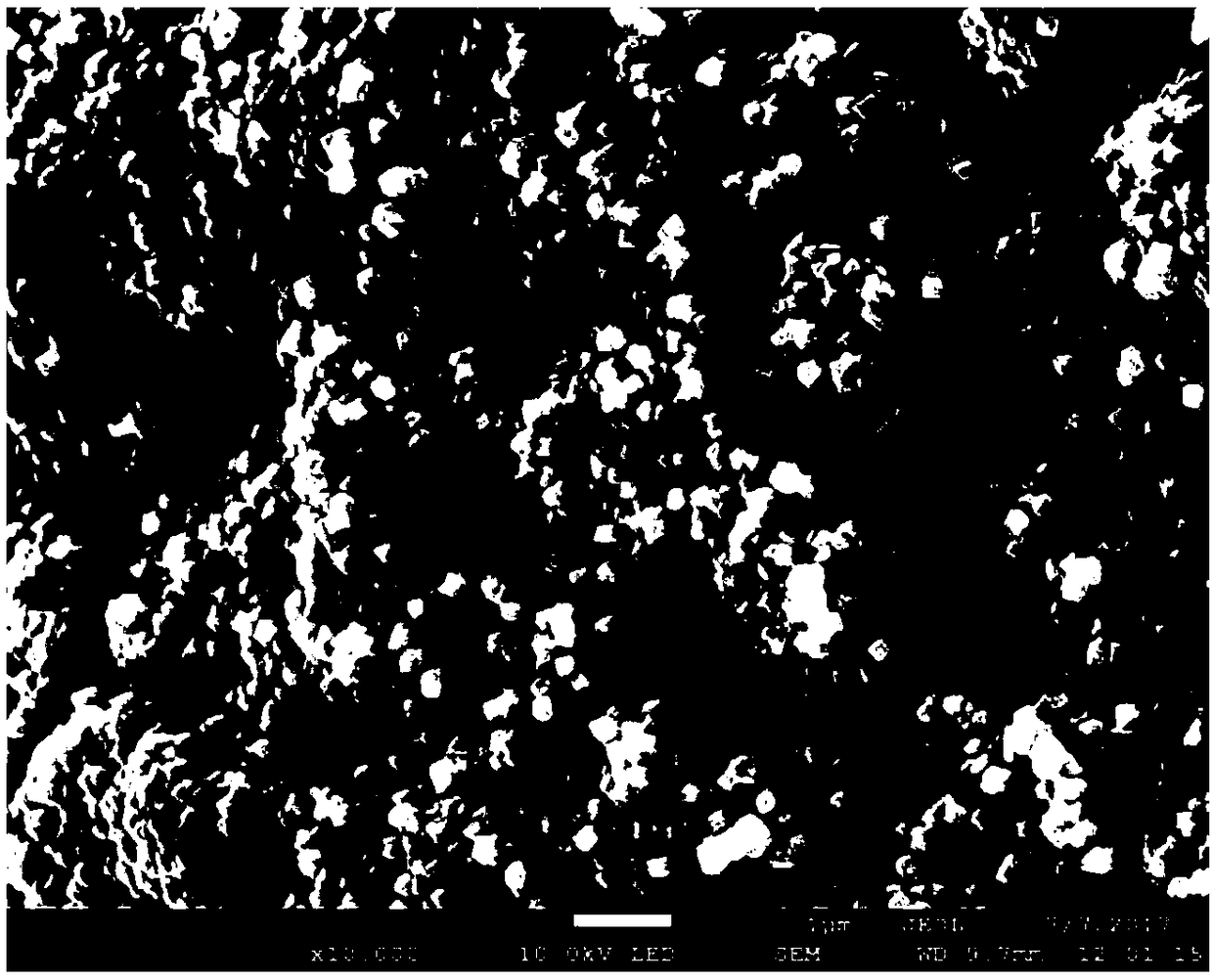

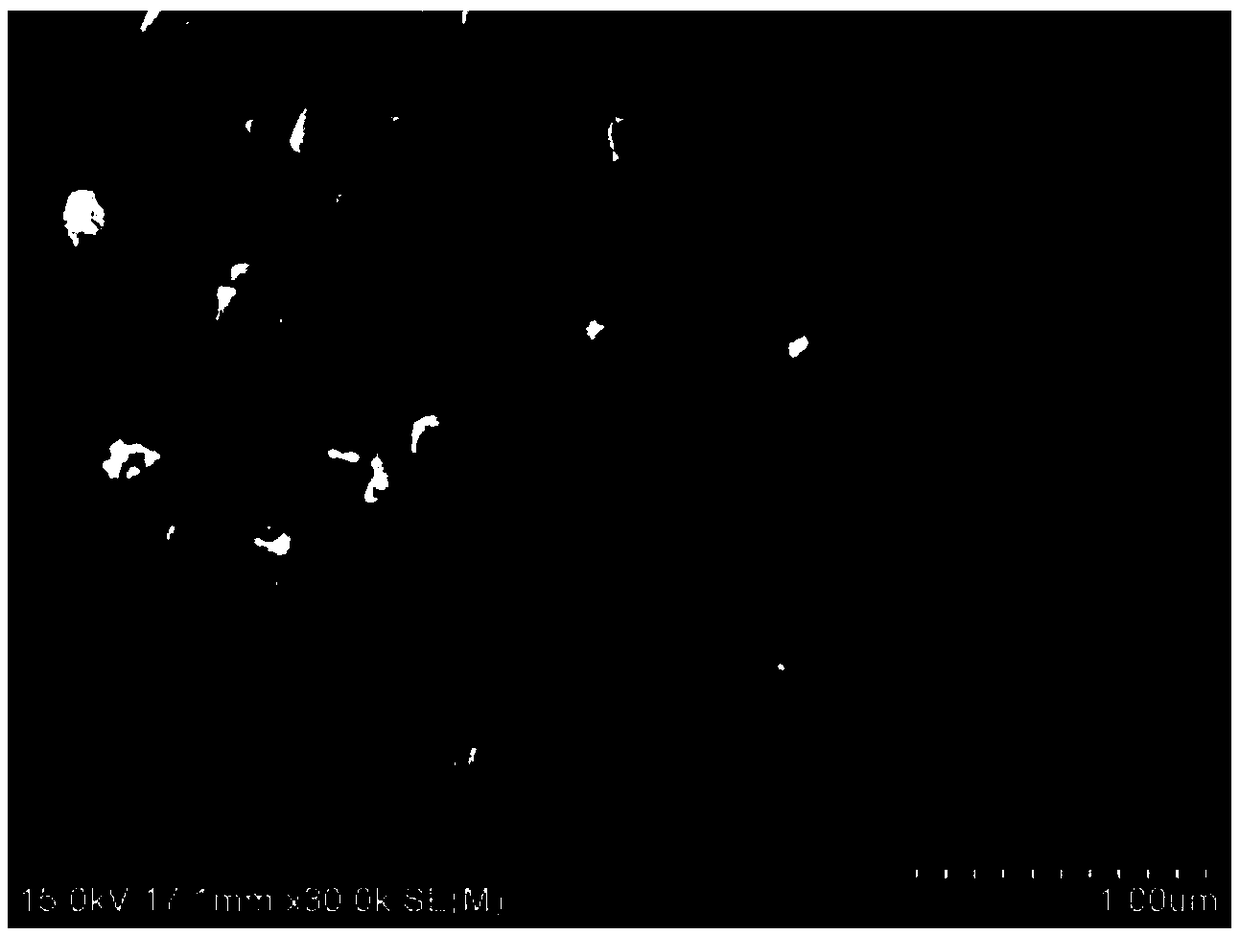

[0034] 3) Vapor-phase deposition of carbon nanofibers: step 2) the carbon fibers coated with the catalyst are evenly wound on the graphi...

Embodiment 2

[0038] A method for preparing a modified carbon fiber microelectrode, comprising the following steps:

[0039] 1) Surface activation: Place a bundle of unsized T800 carbon fibers in absolute ethanol and ultrapure water in sequence, ultrasonically wash them for 5 minutes, and then place them in a nitric acid solution with a concentration of 65% to surface the carbon fibers by plasma oxidation. Activation, the activation temperature is 110°C, the time is 1.5h, and then the nitric acid on the surface of the activated carbon fiber is neutralized with 0.1mol / L NaOH, and the carbon fiber is cleaned with deionized water;

[0040] 2) Coating catalyst: preparing catalyst Ni(NO 3 ) 2 ·6H 2 Immerse the activated carbon fiber in an ethanol solution with an O concentration of 0.5mol / L, take it out after 1 hour, and dry it at 80°C for 30 minutes;

[0041] 3) Vapor-phase deposition of carbon nanofibers: step 2) the carbon fibers coated with the catalyst are evenly wound on the graphite fr...

Embodiment 3

[0045] A method for preparing a modified carbon fiber microelectrode, comprising the following steps:

[0046] 1) Surface activation: Place a bundle of unsized T700 carbon fibers in absolute ethanol and ultrapure water in sequence, ultrasonically wash them for 5 minutes, and then place them in a nitric acid solution with a concentration of 65% to surface the carbon fibers by liquid phase oxidation. Activation, the activation temperature is 120°C, the time is 1h, and then the nitric acid on the activated carbon fiber surface is neutralized with 0.1mol / L NaOH, and the carbon fiber is cleaned with deionized water;

[0047] 2) Coating catalyst: preparing catalyst Ni(NO 3 ) 2 ·6H 2 Immerse the activated carbon fiber in ethanol solution with O concentration of 1mol / L, take it out after 1h, and dry at 80°C for 30min;

[0048] 3) Vapor-phase deposition of carbon nanofibers: step 2) the carbon fibers coated with the catalyst are evenly wound on the graphite frame, put into the CVD v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com