A magnetic nanoparticle based on alkali lignin, its preparation method and its application in the adsorption of copper ions

A technology of magnetic nanoparticles and alkali lignin, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve few problems such as preparation methods and application reports of alkali lignin modified magnetic nanoparticles, and achieve a combination Strong power, low price, and the effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

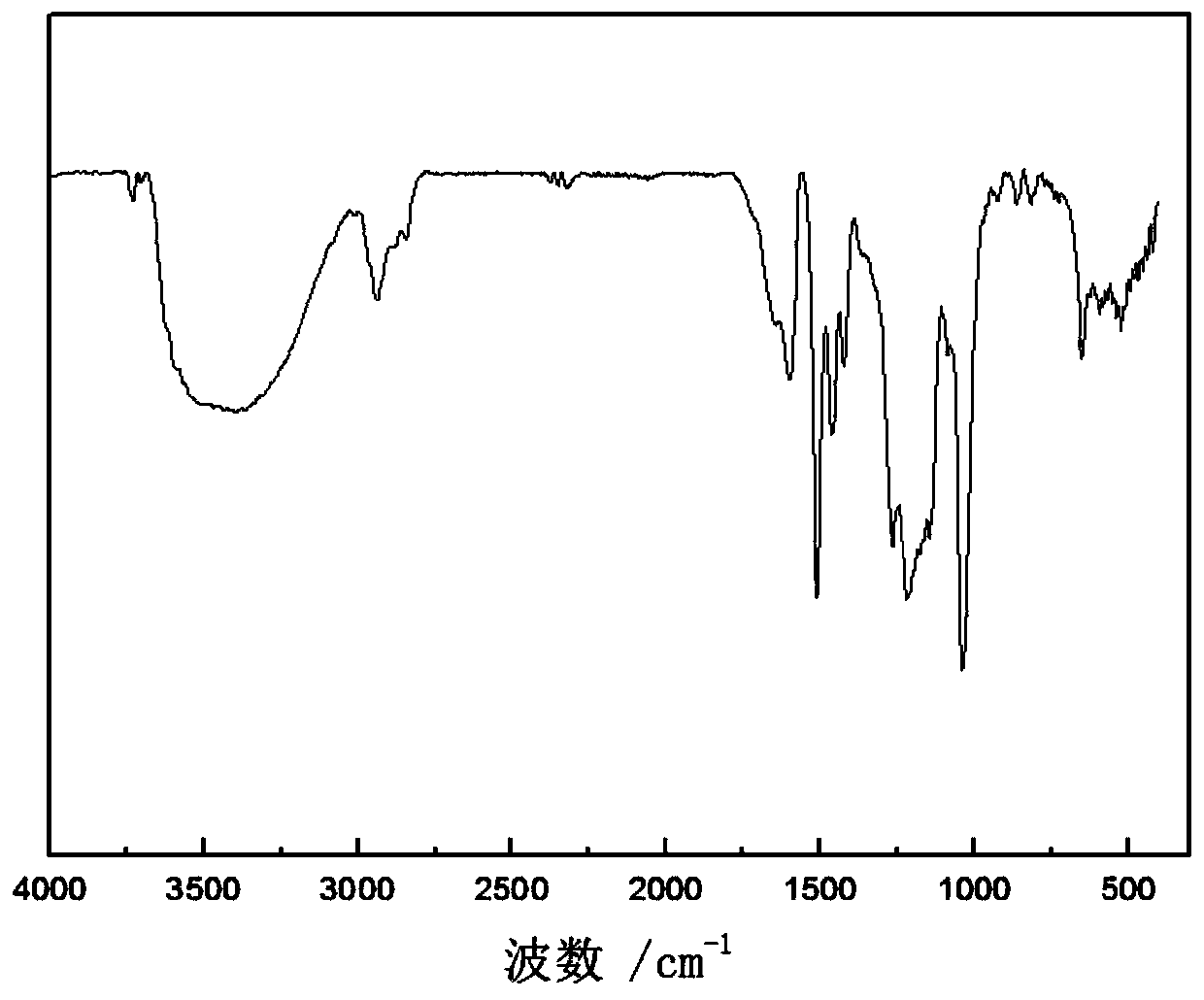

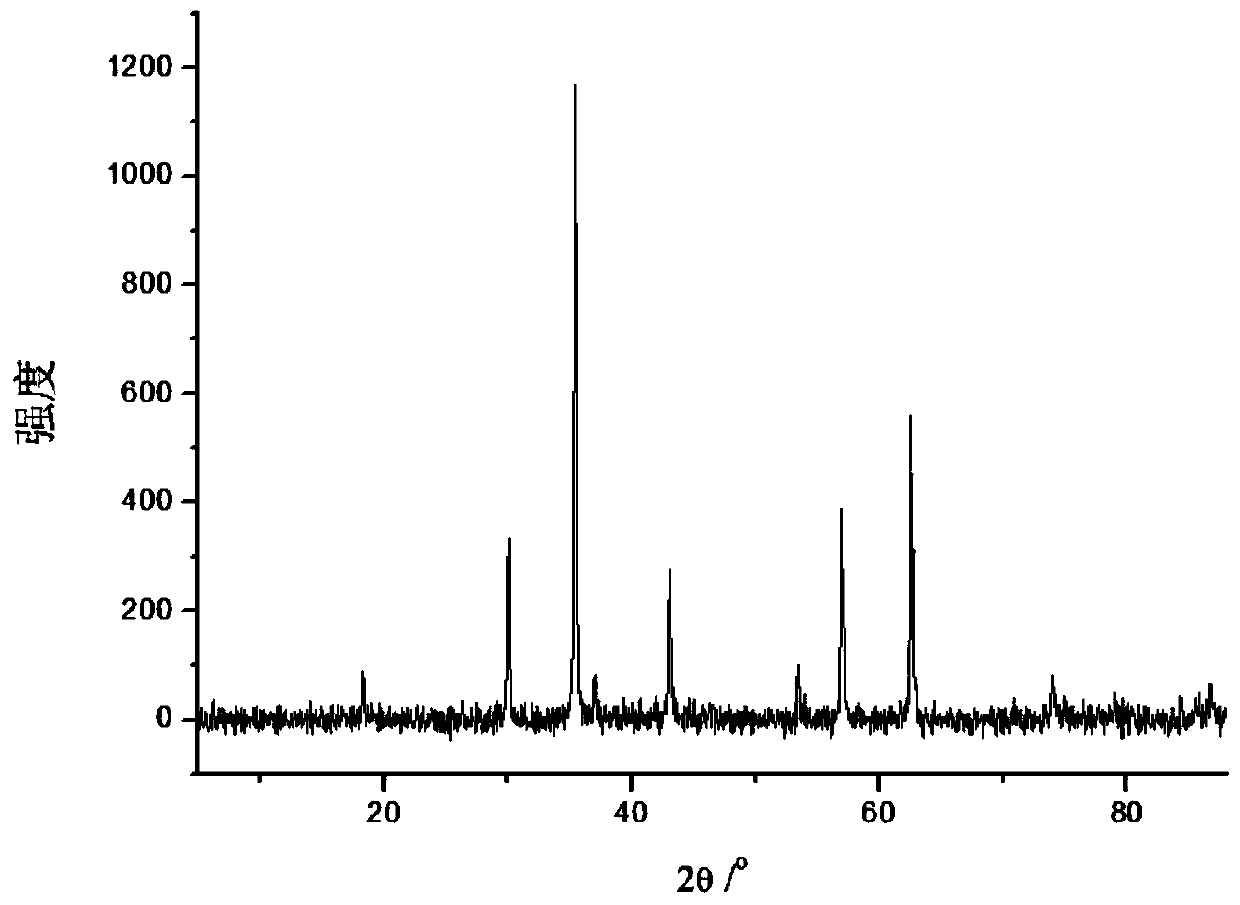

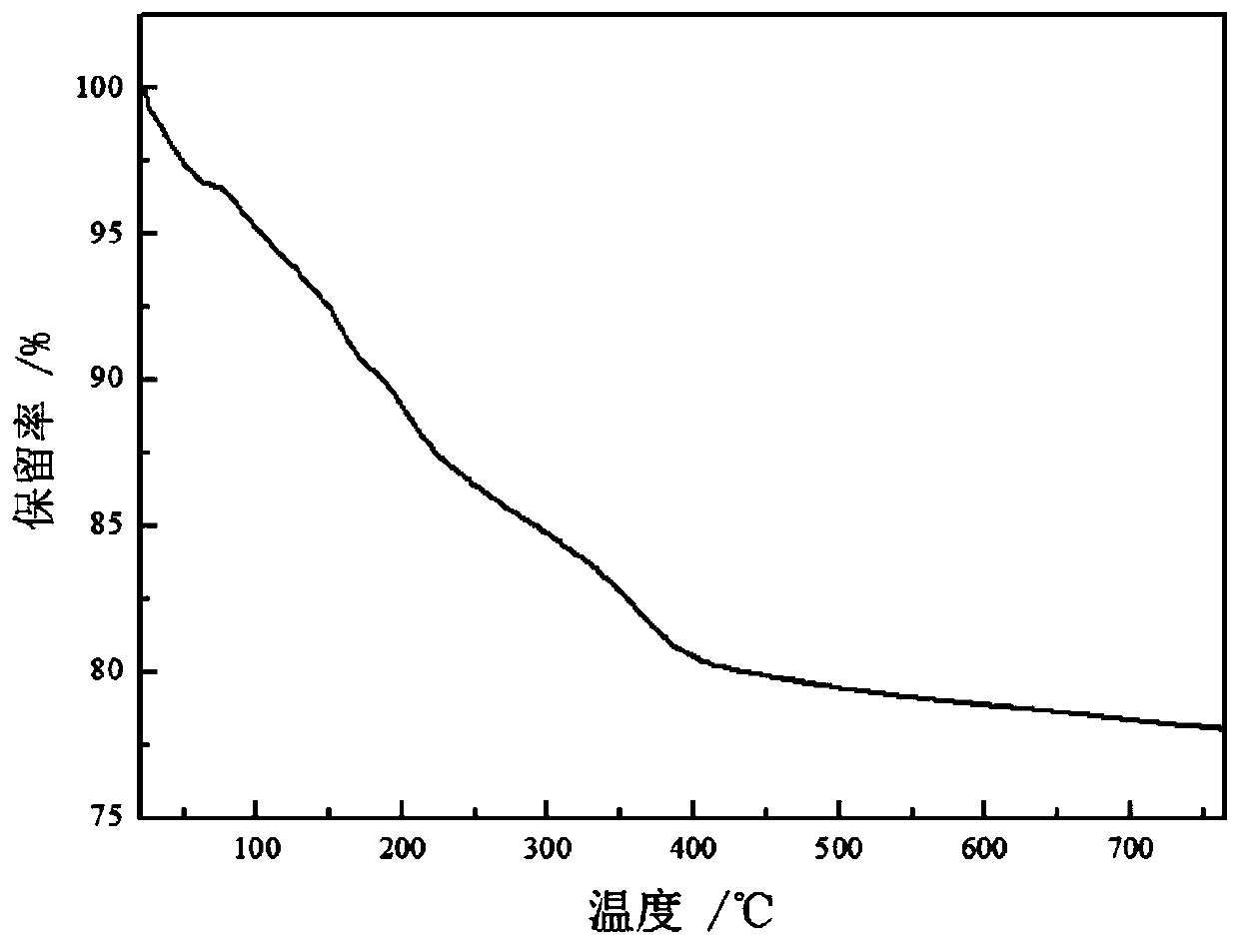

[0041] Dissolve 2.5g of ferrous sulfate and 3g of ferric chloride in 100mL of water, transfer to a four-neck flask, heat up to 85°C under mechanical stirring, slowly drop into 10g of 25% ammonia solution at a rate of 1 drop / second. After the dropwise addition, heat preservation and aging for 3h. After dissolving 2g of wheatgrass lignin into 10g of aqueous solution, drop it into the above reaction system together with 10g of absolute ethanol at the same time, the dropping speed is 1 drop / second, and keep stirring for 2 hours after the dropping is completed. Finally, the magnetic particles are separated by a permanent magnet, washed three times with ethanol, and vacuum-dried at 60° C. to obtain alkali lignin magnetic nanoparticles. Its performance test, the results are as follows.

[0042] Add 1 g of alkali lignin magnetic nanoparticles to 100 mL of Cu with a concentration of 0.05 mol / L 2+ solution, placed on a shaker at a fixed speed at 20°C and oscillated for adsorption. Af...

Embodiment 2

[0049] Dissolve 5g of ferrous sulfate and 6g of ferric chloride in 100mL of water, transfer to a four-necked flask, heat up to 95°C under mechanical stirring, and slowly add 20g of 25% ammonia solution dropwise at a rate of 1 drop / second. After the dropwise addition, heat preservation and aging for 4h. After dissolving 5g of poplar alkali lignin into 20g of aqueous solution, drop it into the above reaction system together with 25g of methanol at the same time, the dropping speed is 1 drop / second, and keep stirring for 1 hour after the dropping is completed. Finally, the magnetic particles are separated by a permanent magnet, washed three times with ethanol, and vacuum-dried at 50° C. to obtain alkali lignin magnetic nanoparticles.

[0050] Add 1 g of alkali lignin magnetic nanoparticles to 100 mL of Cu with a concentration of 0.05 mol / L 2+ solution, placed on a shaker at a fixed speed at 20°C and oscillated for adsorption. After the adsorption is completed, magnetically sepa...

Embodiment 3

[0052] Dissolve 3g of ferrous sulfate and 5g of ferric chloride in 100mL of water, transfer to a four-necked flask, heat up to 75°C under mechanical stirring, slowly drop into 15g of 25% ammonia solution at a rate of 1 drop / second. After the dropwise addition, heat preservation and aging for 2.5 hours. After dissolving 4g of pine alkali lignin into 20g of aqueous solution, drop it into the above reaction system together with 20g of n-propanol at the same time, the dropping rate is 1 drop / second, and keep stirring for 3 hours after the dropping is completed. Finally, the magnetic particles are separated by a permanent magnet, washed three times with ethanol, and vacuum-dried at 70° C. to obtain alkali lignin magnetic nanoparticles.

[0053] Add 1 g of alkali lignin magnetic nanoparticles to 100 mL of Cu with a concentration of 0.05 mol / L 2+ solution, placed on a shaker at a fixed speed at 20°C and oscillated for adsorption. After the adsorption is completed, magnetically sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com