Method for removing trace heavy metal and trace F-53B in electroplating wastewater treatment effluent

A F-53B, electroplating wastewater technology, applied in metallurgical wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of fish embryo development toxicity, high toxicity, and sewage treatment process removal. , to achieve the effect of improving the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

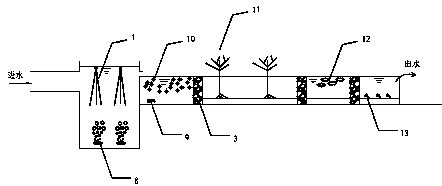

[0023] Such as figure 1 , an advanced treatment method for removing trace heavy metals and traces of F-53B in the effluent of electroplating wastewater treatment. After the terminal sedimentation tank of electroplating wastewater treatment, there are microbial degradation area, algae adsorption area, emergent plant area, floating water plant area and sedimentation tank in sequence. water plant area.

[0024] Put the composite microbial agent in the microbial degradation zone, promote the reproduction and growth of the composite microorganism through the micro-bubble aeration system, and set up carbon fiber filler to provide attachment for the microorganism; the composite microbial agent includes Rhodopseudomonas, Bacillus subtilis, Alcaligenes, actinomycetes, nitrifying bacteria, nitrogen-fixing bacteria, lactic acid bacteria, rhodocyclobacteria, Sclerotia, the content ratio of the compound microbial agent is 2:2:2:1:1:1:0.5 :0.5:0.5, the feeding ratio is 0.2kg / m 3 . Accord...

Embodiment 2

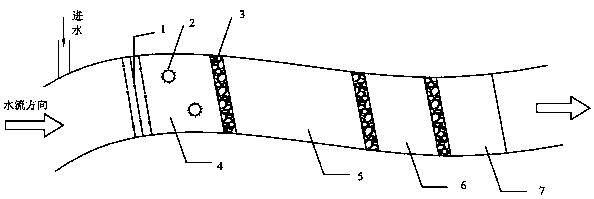

[0032] A certain electroplating wastewater is discharged into natural rivers after treatment, such as figure 2 , each treatment area is set along the natural river, the content ratio of the compound microbial agent is 2:2:2:1:1:1:0.5:0.5:0.5, and the distribution ratio is 0.1kg / m 3 . According to the water surface area every 5m 2 Set and install a carbon fiber tube bundle filler, corresponding to a microbubble aerator with a diameter of 20cm at the bottom of the river. One or more of chlorella, oscillating algae or anabaena are cultivated in the algae adsorption area, and a surface aerator can be installed to make the water in the algae adsorption area evenly mixed. The setting of intercepting net is the same as embodiment one.

[0033] Emergent plant areas, floating plant areas, and submerged plant areas are set along the natural channel. The plants planted in the emergent plant area are cattail and Zailihua, the plants planted in the floating plant area are water lilies...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com