Process system and method for cracking of industrial sludge

A technology of industrial sludge and process system, applied in the field of process system of industrial sludge cracking, can solve the problems of heavy metal affecting the surrounding environment, dioxin polluting the atmosphere, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

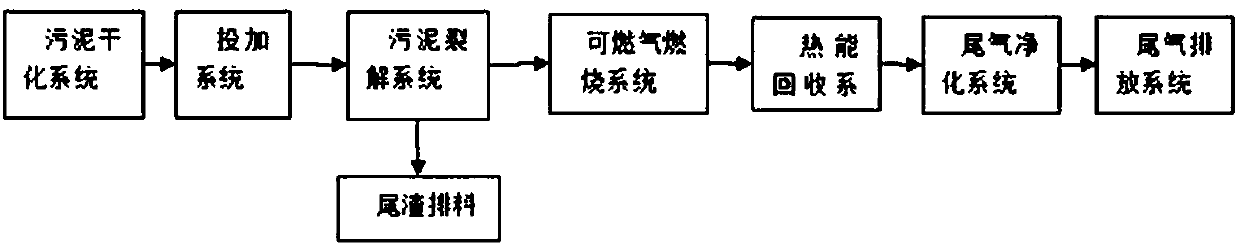

[0030] As a kind of most basic embodiment of the system of the present invention, disclose a kind of process system of industrial sludge pyrolysis, as figure 1 , including sequentially connected drying system, input system, cracking system, combustible gas combustion system, heat energy recovery system and tail gas treatment system; the sludge cracking system is also connected to a tailings discharge port; the combustible gas combustion system includes A combustion tower with an oxygen supply pipeline; the tail gas treatment system includes a tail gas cooling system and a tail gas purification system. During the disposal process, the dried sludge is cracked in the sludge cracker at a temperature of 600-800 ° C, and the organic matter is cracked into low-molecular combustible gases such as methane and carbon monoxide. After sludge treatment, on the one hand, the discharge of harmful substances is reduced, and on the other hand, resources are recovered.

Embodiment 2

[0032] As a preferred embodiment of the system of the present invention, a process system for cracking industrial sludge is disclosed, such as figure 1 , including sequentially connected drying system, input system, cracking system, combustible gas combustion system, heat energy recovery system and tail gas treatment system; the sludge cracking system is also connected to a tailings discharge port; the combustible gas combustion system includes A combustion tower with an oxygen supply pipeline; the tail gas treatment system includes a tail gas cooling system and a tail gas purification system; The feed rate can be guaranteed, and the amount of oxygen brought into the cracking system can be guaranteed to be small, so as to ensure the safety of the cracking process; the cracking system includes a double-layer heating tube with a control device, and the conveying spiral channel passes through the cracking system. Double-layer heating pipes are arranged; electric heating wires are...

Embodiment 3

[0034] As a most basic embodiment of the method of the present invention, a process method for cracking industrial sludge is disclosed, including a drying step, dehydrating the sludge through a dryer, so that the moisture content in the sludge is within 30%; In the cracking step, the sludge that has undergone the drying step is fed into the cracking system at a constant speed, and is cracked at a temperature of 600~800°C for at least 30 minutes; in the combustible gas combustion step, the combustible gas generated in the cracking step is transported into the combustion chamber , and mixed with oxygen to carry out combustion treatment in the combustion chamber; tail gas treatment step, the tail gas generated in the combustible gas combustion step is subjected to desulfurization, denitrification, dust removal and heavy metal removal treatment until it reaches the standard and then discharged. The closest conventional sludge treatment method to this technology is the incineration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com