A polymer base functional film and a preparing method therefor

A polymer film and polymer technology, applied in coatings, photovoltaic power generation, electrical components, etc., can solve the problems of no natural products, etc., and achieve the effect of improving photoelectric performance, simple method, and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

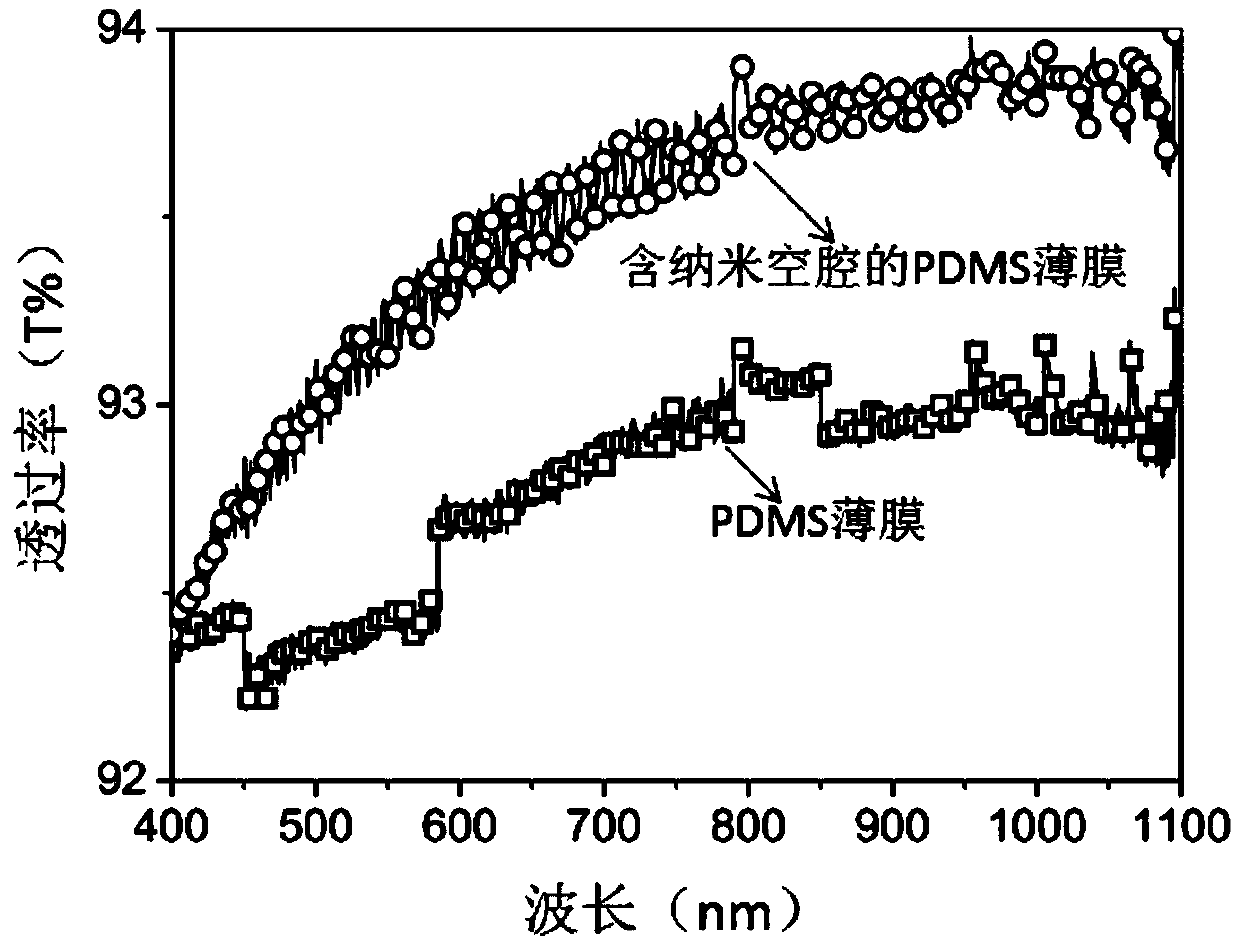

Embodiment 1

[0069] (1) Dissolve the polymer in toluene, the mass ratio of polymer to toluene is 1:7, magnetically stir for 1h, 5000rpm / min high-speed stirring for 10min, ultrasonic for 1h, after the polymer is completely dissolved, a uniform and transparent polymerization is obtained solution in toluene. Disperse the nano-sacrificial template in toluene, the mass ratio of the nano-sacrificial template to toluene is 1:10, and sonicate for 2 hours to obtain a uniformly mixed toluene solution containing the nano-sacrificial template. Then with the mass ratio of the nano-sacrifice template in the solution that finally forms is the amount that the toluene solution of polymer and the toluene solution that contains nano-sacrifice template are mixed, obtain composite colloid solution (wherein the mass fraction of polymer is 15%) , wherein the nano sacrificial template is oily monodisperse cadmium selenide (CdSe) quantum dots (3-5nm), and the polymer is polydimethylsiloxane (PDMS).

[0070] (2) G...

Embodiment 2

[0073] (1) Dissolve the polymer in the organic solvent toluene, the mass ratio of the polymer to toluene is 1:7, stir magnetically for 1 hour, stir at a high speed of 5000rpm / min for 10 minutes, and sonicate for 1 hour. After the polymer is completely dissolved, a uniform and transparent The toluene solution of the polymer; dissolve the nano-sacrificial template in toluene, the mass ratio of the nano-sacrificial template to toluene is 1:10, and ultrasonicate for 2 hours to obtain a uniformly mixed toluene solution containing the nano-sacrificial template, and then use the final solution The mass ratio of the nano-sacrifice template is 1 wt%. The toluene solution of the polymer and the toluene solution containing the nano-sacrifice template are mixed to obtain a composite colloid solution (wherein the mass fraction of the polymer is 10%) as the first solution. Wherein, the nano sacrificial template is an oil-soluble monodisperse cadmium selenide (CdSe) quantum dot (3-5nm), and t...

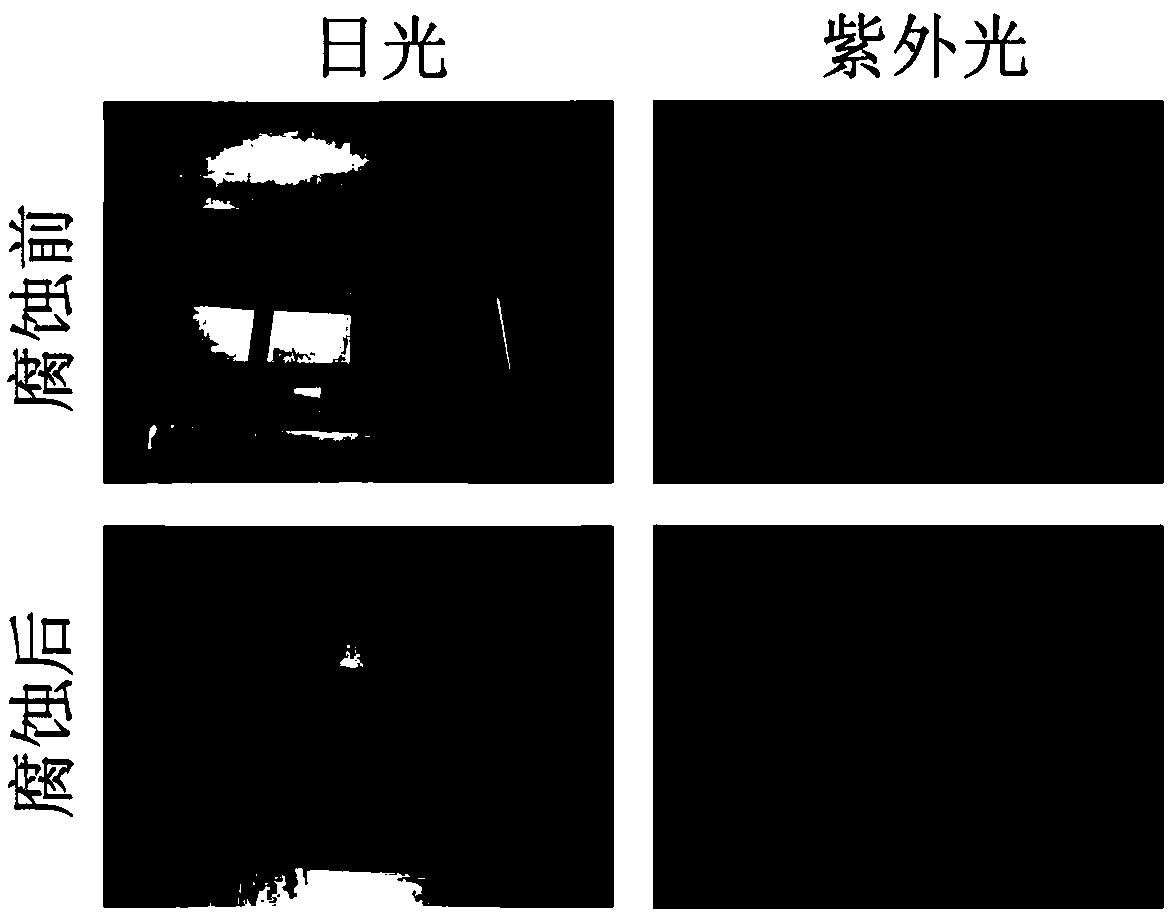

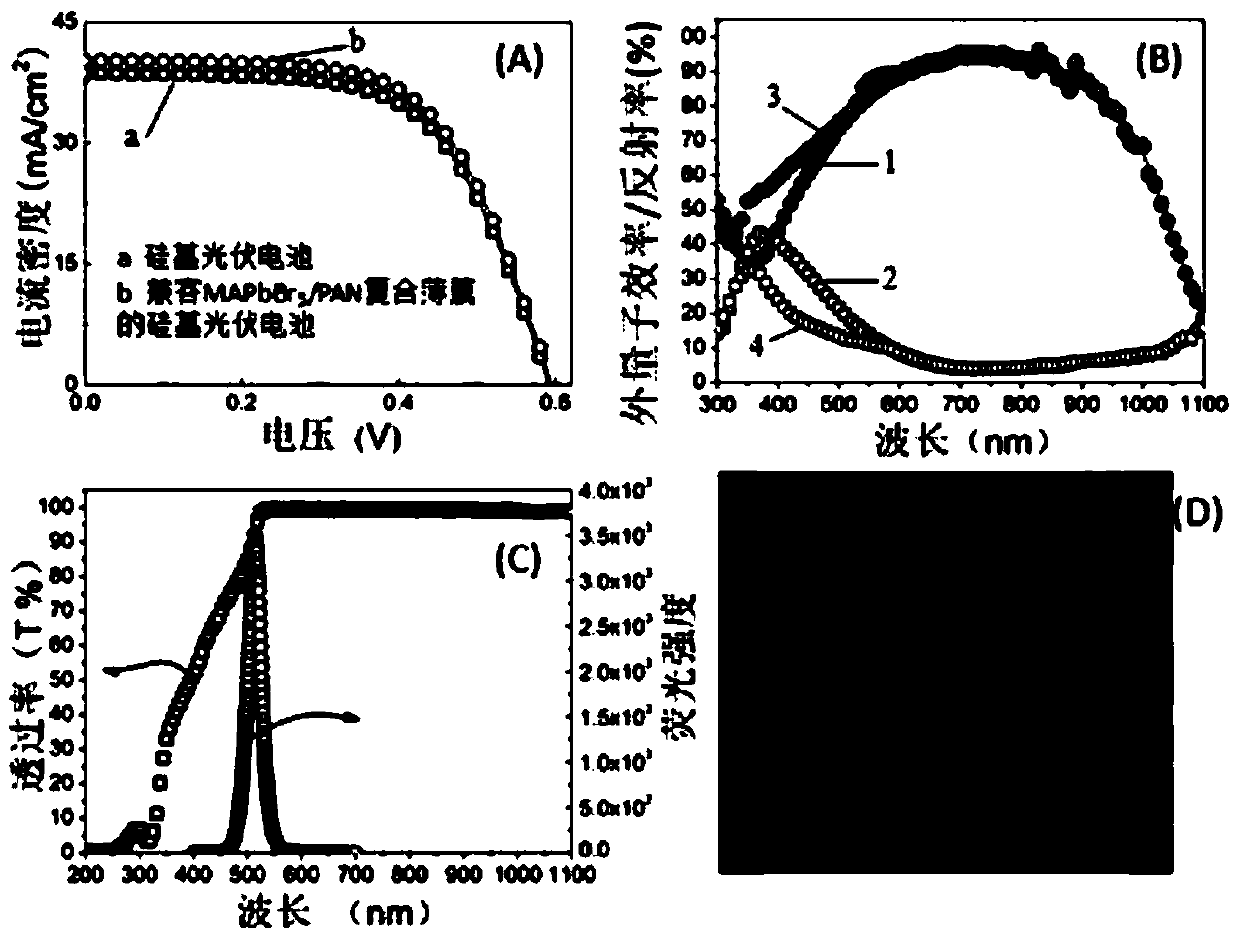

Embodiment 3

[0081] (1) Dissolve the polymer in the organic solvent N,N-dimethylformamide (DMF), the mass ratio of the polymer to the organic solvent is 1:8, magnetic stirring for 1h, 5000rpm / min high-speed stirring for 10min, ultrasonication for 1h After the polymer is completely dissolved, a uniform and transparent polymer solution is obtained as the first solution; the polymer is polyacrylonitrile (PAN).

[0082] (2) Mix the inorganic halide salt and organic ammonium halide salt powder, wherein the molar ratio of inorganic halide salt:organic ammonium halide salt is 1:1.5, and then add N,N-dimethylformamide (DMF) The mass ratio of N,N-dimethylformamide (DMF) to inorganic halide salts is 1:0.09. After mixing, ultrasonic treatment is performed. After ultrasonic treatment for 15 minutes, a transparent mixed solution is obtained. Liquid is filtered, and the filtrate obtained by filtration is taken as the second solution; the inorganic halide salt described in this step is lead bromide (PbBr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com