PC/PMMA/PETG ternary alloy material and preparation method thereof

A ternary alloy and raw material technology, applied in the field of PC/PMMA/PETG ternary alloy material and its preparation, can solve the problems of abnormal water-marked silver wire injection molding, easy decomposition of small molecules, low bending elastic modulus, etc. Low cost, good practical prospects and social and economic benefits, the effect of improving bending elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

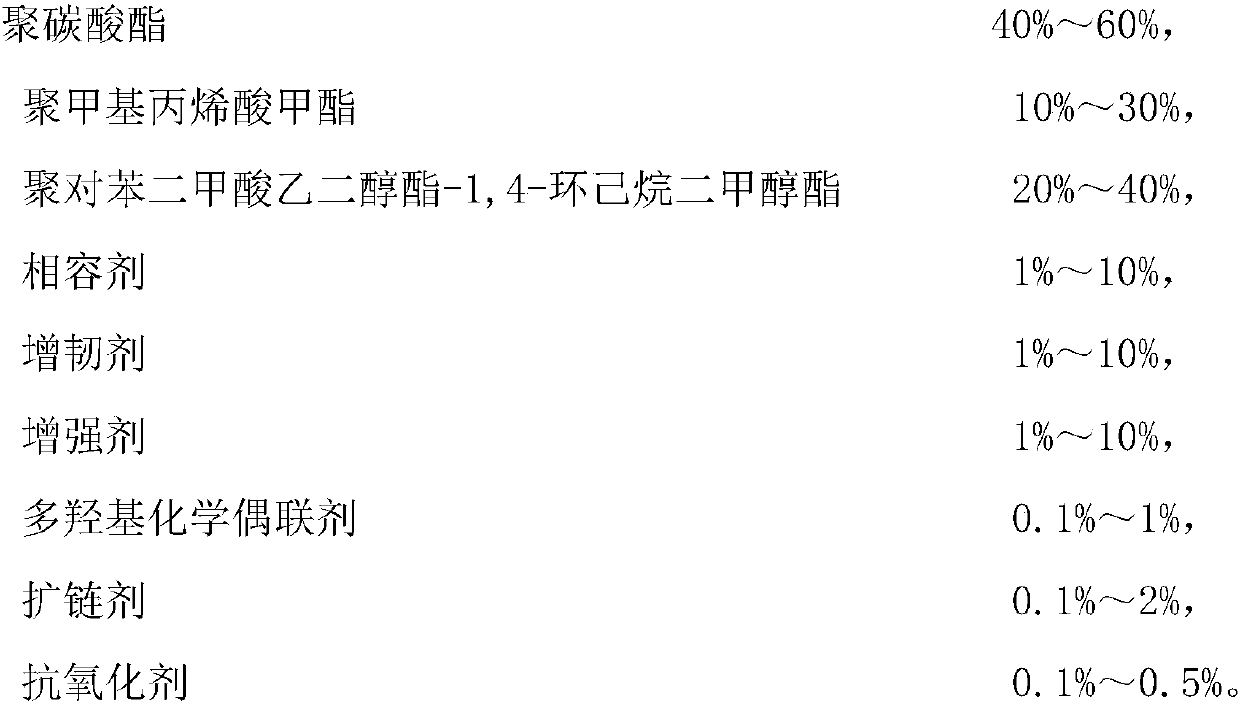

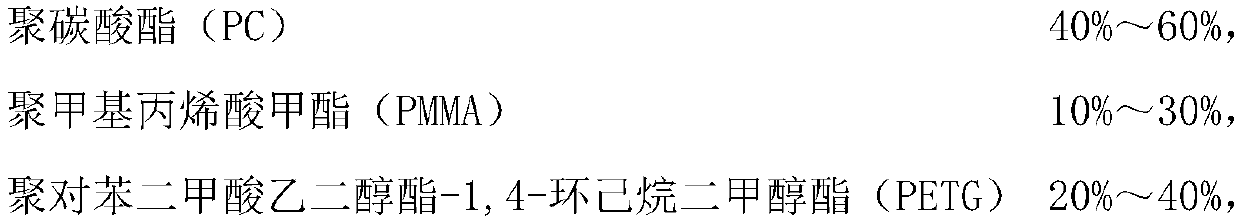

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of PC / PMMA / PETG ternary alloy material, it comprises the following steps:

[0034] Step 1) Weigh the raw material components according to the following mass percentages: polycarbonate 50.4%, polymethyl methacrylate 12.6%, polyethylene terephthalate-1,4-cyclohexanedimethanol 27% , ABS-g-MAH 3%, butadiene content greater than or equal to 55% ABS high rubber powder 3%, organic montmorillonite 3%, pentaerythritol 0.2%, styrene-acrylonitrile-glycidyl methacrylate copolymer 0.5% tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.2%, tris(2,4-di-tert-butyl)phenyl phosphite 0.1%.

[0035] The polycarbonate is a high-molecular-weight polycarbonate resin recycled material after sorting, purification, crushing, cleaning, and drying. It does not contain flame retardants, and its melt index is ≤15g / 10min; the drying environment is 95°C, and the drying time is 1.5 hours.

[0036] The polymethyl methacrylate is an injection gr...

Embodiment 2

[0042] The preparation method of PC / PMMA / PETG ternary alloy material, it comprises the following steps:

[0043] Step 1) Weigh the raw material components according to the following mass percentages: polycarbonate 43.2%, polymethyl methacrylate 10.8%, polyethylene terephthalate-1,4-cyclohexanedimethanol 36% , AS-g-MAH 5%, methyl methacrylate-butadiene-styrene terpolymer 2%, fumed nano-silica 2%, glycerin 0.2%, styrene-acrylonitrile-methacrylic acid shrink Glyceride copolymer 0.5%, β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 0.2%, tris(2,4-di-tert-butyl)phenylphosphite Esters 0.1%.

[0044] The polycarbonate is a high-molecular-weight polycarbonate resin recycled material after sorting, purification, crushing, cleaning, and drying. It does not contain flame retardants, and its melt index is ≤15g / 10min; the drying environment is 95°C, and the drying time is 1.5 hours.

[0045] The polymethyl methacrylate is an injection grade polymethyl methacrylate resin reg...

Embodiment 3

[0051] The preparation method of PC / PMMA / PETG ternary alloy material, it comprises the following steps:

[0052] Step 1) Weigh the raw material components according to the following mass percentages: polycarbonate 37.8%, polymethyl methacrylate 16.2%, polyethylene terephthalate-1,4-cyclohexanedimethanol 36% , PS-g-MAH 4%, polyolefin thermoelastomer 1%, nano calcium carbonate 4%, glyceryl monostearate 0.2%, styrene-acrylonitrile-glycidyl methacrylate copolymer 0.5%, 0.2% n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, 0.1% trinonylphenyl phosphite.

[0053] The polycarbonate is a high-molecular-weight polycarbonate resin recycled material after sorting, purification, crushing, cleaning, and drying. It does not contain flame retardants, and its melt index is ≤15g / 10min; the drying environment is 95°C, and the drying time is 1.5 hours.

[0054] The polymethyl methacrylate is an injection grade polymethyl methacrylate resin regenerated material after sorting, purif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com