Recycling method for ion type rare-earth ore smelting and separating magnesium salt wastewater

An ion-type rare earth ore and resource utilization technology is applied in the field of resource utilization of ion-type rare earth ore smelting and separation magnesium salt wastewater. Recycling effect, effect of promoting transformation and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

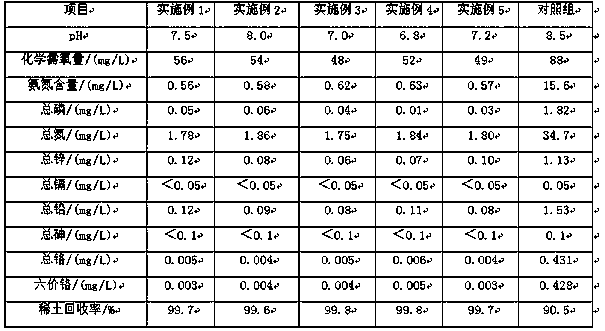

Examples

Embodiment 1

[0028]The extract components of plant A are the extract components after the combination of seaweed, kelp, mustard, angelica, cloves, and mint in a weight ratio of 1:1:1:1:1:1;

[0029] The extract component of plant B is the extract component after mixing false physalis, clover, and sorrel according to the weight ratio of 1:1:1;

[0030] Preparation of plant A extract components: seaweed, kelp, fenugreek, angelica, cloves, and mint are mixed in a weight ratio of 1:1:1:1:1:1 and then pulverized, and a certain amount of distilled water is added to make the material-to-liquid ratio 1:30 , stirred and soaked at 80°C for 11h, and then carried out ultrasonic extraction, the ultrasonic extraction power was 1150w, and the extraction time was 23min, and then the filter residue and filtrate were separated by filtration, and the filter residue was repeatedly extracted for 3 times. Filtrate, the total filtrate is concentrated so that the concentrated solution volume is 1 / 5 of the origina...

Embodiment 2

[0035] The extract components of plant A are the extract components after the combination of seaweed, kelp, mustard, angelica, cloves, and mint in a weight ratio of 1:1:1:1:1:1;

[0036] The extract component of plant B is the extract component after mixing false physalis, clover, and sorrel according to the weight ratio of 1:1:1;

[0037] Preparation of plant A extract components: seaweed, kelp, fenugreek, angelica, cloves, and mint are mixed in a weight ratio of 1:1:1:1:1:1 and then pulverized, and a certain amount of distilled water is added to make the material-to-liquid ratio 1:30 , stirred and soaked for 10 hours at 70 °C, and then carried out ultrasonic extraction. The ultrasonic extraction power was 1000w, and the extraction time was 25 minutes. Then, the filter residue and the filtrate were separated by filtration. The filter residue was repeatedly extracted for 3 times. Filtrate, the total filtrate is concentrated so that the concentrated solution volume is 1 / 5 of th...

Embodiment 3

[0042] The extract components of plant A are the extract components after the combination of seaweed, kelp, mustard, angelica, cloves, and mint in a weight ratio of 1:1:1:1:1:1;

[0043] The extract component of plant B is the extract component after mixing false physalis, clover, and sorrel according to the weight ratio of 1:1:1;

[0044] Preparation of plant A extract components: seaweed, kelp, fenugreek, angelica, cloves, and mint are mixed in a weight ratio of 1:1:1:1:1:1 and then pulverized, and a certain amount of distilled water is added to make the material-to-liquid ratio 1:30 , stirred and soaked at 78°C for 10.5 hours, and then carried out ultrasonic extraction. The ultrasonic extraction power was 1200w and the extraction time was 20min. Then the filter residue and the filtrate were separated by filtration. Total filtrate, the total filtrate is concentrated so that the concentrated solution volume is 1 / 5 of the original total filtrate volume to obtain the plant A ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com