Thermal insulating Nixing pottery teapot and production method thereof

A technology of thermal insulation and production method, applied in the field of ceramic products, can solve the problems of high thermal conductivity, poor thermal insulation effect, poor thermal insulation effect, etc., and achieves the effects of low thermal conductivity, improved kiln variability, and reduced shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

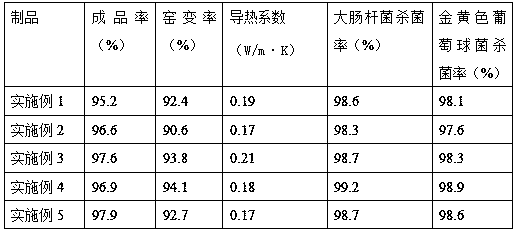

Examples

Embodiment 1

[0028] A heat-insulating and heat-preserving pottery teapot, comprising the following raw materials in parts by weight: 65 parts by weight of eastern mud, 50 parts of western mud, 15 parts of attapulgite, 10 parts of serpentine, 8 parts of rock wool, and 4 parts of aluminum silicate fiber Parts, 8 parts of oyster shell, 2.5 parts of hydroxyapatite, 1.5 parts of titanium dioxide and 4 parts of sintering aid. The sintering aid is composed of manganese dioxide, yttrium oxide and magnesium oxide with a mass ratio of 1:0.5:2.5.

[0029] The east mud and west mud are obtained by pretreatment as follows: the weathered east mud and west mud are respectively pulverized to 20 mesh with a ball mill and covered with plastic film. After 10 days of aging, the above east mud and west mud can be obtained. West mud.

[0030] The manufacturing method of the heat insulation and heat preservation Nixing pottery teapot includes the following steps:

[0031] (1) Weigh the raw materials according to the ...

Embodiment 2

[0036] A heat-insulating and heat-preserving pottery teapot, comprising the following raw materials in parts by weight: 70 parts by weight of eastern mud, 40 parts of western mud, 12 parts of attapulgite, 12 parts of serpentine, 6 parts of rock wool, 5 parts of aluminum silicate fiber Parts, 7 parts of oyster shell, 1.5 parts of hydroxyapatite, 2 parts of titanium dioxide and 5 parts of sintering aid. The sintering aid is composed of manganese dioxide, yttrium oxide and magnesium oxide with a mass ratio of 1:1:3.

[0037] The east mud and west mud are obtained by pretreatment as follows: the weathered east mud and west mud are respectively pulverized to 20 mesh with a ball mill and covered with plastic film. After 15 days of aging, the above east mud and west mud can be obtained. West mud.

[0038] The manufacturing method of the heat insulation and heat preservation Nixing pottery teapot includes the following steps:

[0039] (1) Weigh the raw materials according to the above-ment...

Embodiment 3

[0044] A heat-insulating and heat-preserving pottery teapot, comprising the following raw materials in parts by weight: 50 parts by weight of eastern mud, 50 parts of western mud, 20 parts of attapulgite, 15 parts of serpentine, 10 parts of rock wool, and 3 parts of aluminum silicate fiber Parts, 8 parts of oyster shell, 3 parts of hydroxyapatite, 1 part of titanium dioxide and 3.5 parts of sintering aid. The sintering aid is composed of manganese dioxide, yttrium oxide and magnesium oxide with a mass ratio of 1:0.5:2.

[0045] The east mud and west mud are obtained by pretreatment as follows: the weathered east mud and west mud are respectively pulverized to 40 mesh with a ball mill and covered with plastic film. After 7 days of aging, the above east mud and west mud can be obtained. West mud.

[0046] The manufacturing method of the heat insulation and heat preservation Nixing pottery teapot includes the following steps:

[0047] (1) Weigh the raw materials according to the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com