SrTiO3 nanometer material preparation method

A nanomaterial, ethylene glycol technology, used in chemical instruments and methods, inorganic chemistry, titanium compounds, etc., can solve the problems of long synthesis time and long reaction process, and achieve narrow particle size distribution, easy operation, and fine particles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A SrTiO 3 The preparation method of nanometer material specifically comprises the following steps:

[0022] (1) Dissolve citric acid, butyl titanate, and strontium chloride hexahydrate in 50mL of methanol, and add ethylene glycol as a dispersant at the same time to obtain a mixed solution. The amount of citric acid added to the mixed solution is 13.7432g, The added amount of butyl titanate was 3.7852 g, the added amount of strontium chloride hexahydrate was 2.9207 g, and the added amount of ethylene glycol was 3 mL.

[0023] (2) Foam the mixed solution obtained in step (1) at 90°C to form a gel, heat the reaction until no precipitation is formed during the foaming and forming process, and the time required for forming the gel is 20 minutes.

[0024] (3) Dry the colloid obtained in step (2) (dried at 180°C for 1 hour) to obtain a xerogel; the obtained xerogel is calcined (calcined at 800°C for 5 hours) to obtain SrTiO 3 Material.

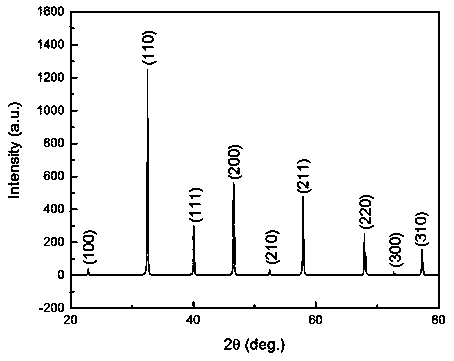

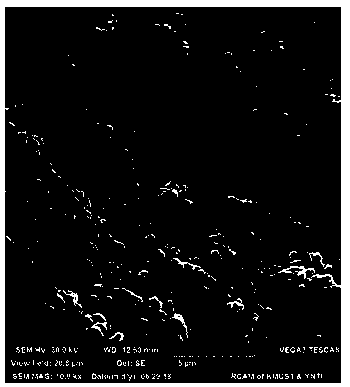

[0025] The SrTiO prepared in this em...

Embodiment 2

[0028] A SrTiO 3 The preparation method of nanometer material specifically comprises the following steps:

[0029] (1) Dissolve citric acid, butyl titanate, and strontium chloride hexahydrate in 50mL of methanol, and add ethylene glycol as a dispersant at the same time to obtain a mixed solution. The amount of citric acid added to the mixed solution is 13.7432g, The added amount of butyl titanate was 3.7852 g, the added amount of strontium chloride hexahydrate was 2.9207 g, and the added amount of ethylene glycol was 3 mL.

[0030] (2) Foam the mixed solution obtained in step (1) at 80°C to form a gel, heat the reaction until no precipitation is formed during the foaming and forming process, and the time required for forming the gel is 25 minutes.

[0031] (3) Dry the colloid obtained in step (2) (dried at 190°C for 1 hour) to obtain a dry gel; the obtained dry gel is calcined (calcined at 900°C for 3.5 hours) to obtain SrTiO 3 Material.

[0032] The SrTiO prepared in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com