A kind of preparation method of resistive diamond-like carbon base film material

A thin-film material, diamond technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of specific technical measures and means of surface resistivity of diamond-like carbon-based thin films, etc., and achieve good results. Application prospect and value, good thickness uniformity, strong film-base bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

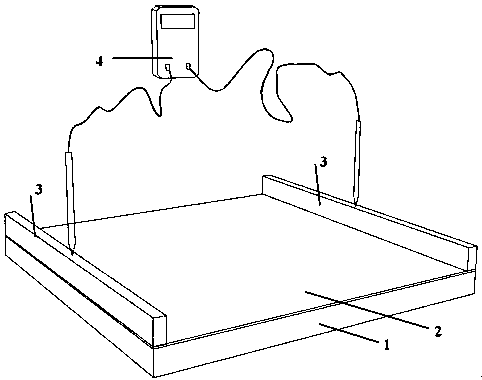

Image

Examples

Embodiment 1

[0023] In this embodiment, a resistive diamond-like carbon-based thin film material with a surface resistivity of 10±2 MΩ / □ was prepared on a polyimide film substrate, and the uniformity was good.

[0024] Specifically include the following steps:

[0025] Step 1. The surface of the high-purity graphite target is sputtered and cleaned.

[0026] The vacuum degree of the background in the pre-evacuation chamber is 1×10 -5 Below Torr, turn on the pulsed DC power supply, apply a bias voltage of -500~-50 V gradient, and apply a current of 3.0 A on the high-purity graphite target with a strong magnetic field, and feed a high-purity argon gas with a flow rate of 18 sccm. The surface of the high-purity graphite target is cleaned by sputtering with ionized argon ions for 35 minutes.

[0027] Step 2, cleaning and drying the surface of the substrate to be plated.

[0028] Take a polyimide film material with a size of 150 mm×150 mm, wipe and clean its surface with absolute ethanol, pl...

Embodiment 2

[0035] In this embodiment, a resistive diamond-like carbon-based film material with a surface resistivity of 50±10 MΩ / □ was prepared on a polyimide film substrate, and the uniformity was good.

[0036] Specifically include the following steps:

[0037] Step 1. The surface of the high-purity graphite target is sputtered and cleaned.

[0038] Same as Step 1 in Example 1.

[0039] Step 2, cleaning and drying the surface of the substrate to be plated.

[0040]Same as Step 2 in Example 1.

[0041] Step 3, plasma bombardment activation and etching on the surface of the substrate to be plated.

[0042] Same as Step 3 in Example 1.

[0043] Step 4, preparing a resistive diamond-like carbon-based thin film material with a surface resistivity of 50±10 MΩ / □.

[0044] Keep the working air pressure at 6×10 -4 Torr, the rotation speed of the sample holder is 10 rpm, the applied substrate bias is -30 V, the target current is 2.0 A, after sputtering deposition for 20 minutes, it is coo...

Embodiment 3

[0047] In this embodiment, a resistive diamond-like carbon-based thin film material with a surface resistivity of 80±10 MΩ / □ was prepared on a polyimide film substrate, and the uniformity was good.

[0048] Specifically include the following steps:

[0049] Step 1. The surface of the high-purity graphite target is sputtered and cleaned.

[0050] Same as step 1 in examples 1 and 2.

[0051] Step 2, cleaning and drying the surface of the substrate to be plated.

[0052] Same as step 2 in examples 1 and 2.

[0053] Step 3, plasma bombardment activation and etching on the surface of the substrate to be plated.

[0054] Same as step 3 in examples 1 and 2.

[0055] Step 4, preparing a resistive diamond-like carbon-based thin film material with a surface resistivity of about 80±10 MΩ / □.

[0056] Keep the working air pressure at 6×10 -4 Torr, the rotation speed of the sample holder was 10 rpm, the applied substrate bias was -30 V, and the target current was set to 1.6 A. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com